Bore Inspection automation Using Machine Vision AI and Borescope Cameras

Published on: Dec 06, 2024

Written by: Soumen das

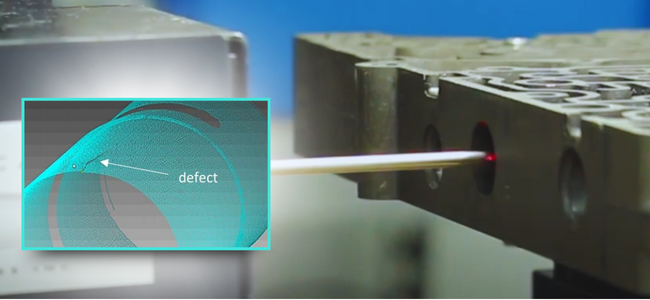

Lower diameter Bore inspection using Integic’s Live Vision AI software and Borescope camera.

Bore inspection is a critical process in industries like aerospace, automotive, and heavy machinery manufacturing, where precision and quality control are paramount. The interior surfaces of bores, cylindrical cavities, or narrow channels in metal components are often inaccessible for traditional inspection methods. Machine Vision AI Software combined with borescope cameras offers an innovative and efficient solution to overcome these challenges, delivering unparalleled accuracy and automation in detecting defects inside bores.

This article explores the significance of bore inspection, the role of borescope cameras, the integration of AI-powered machine vision software, and the applications of this advanced inspection solution in various industries.

What Is Bore Inspection?

Bore inspection involves examining the interior surfaces of cylindrical cavities or narrow, confined spaces in metal components. This process is essential to ensure that the bores are free of defects such as:

-

Surface scratches or grooves

-

Pitting and corrosion

-

Burrs or machining marks

-

Cracks or fractures

-

Dimensional irregularities

-

Foreign particles or residues

These defects can compromise the structural integrity and functionality of the component, potentially leading to failures in critical applications.

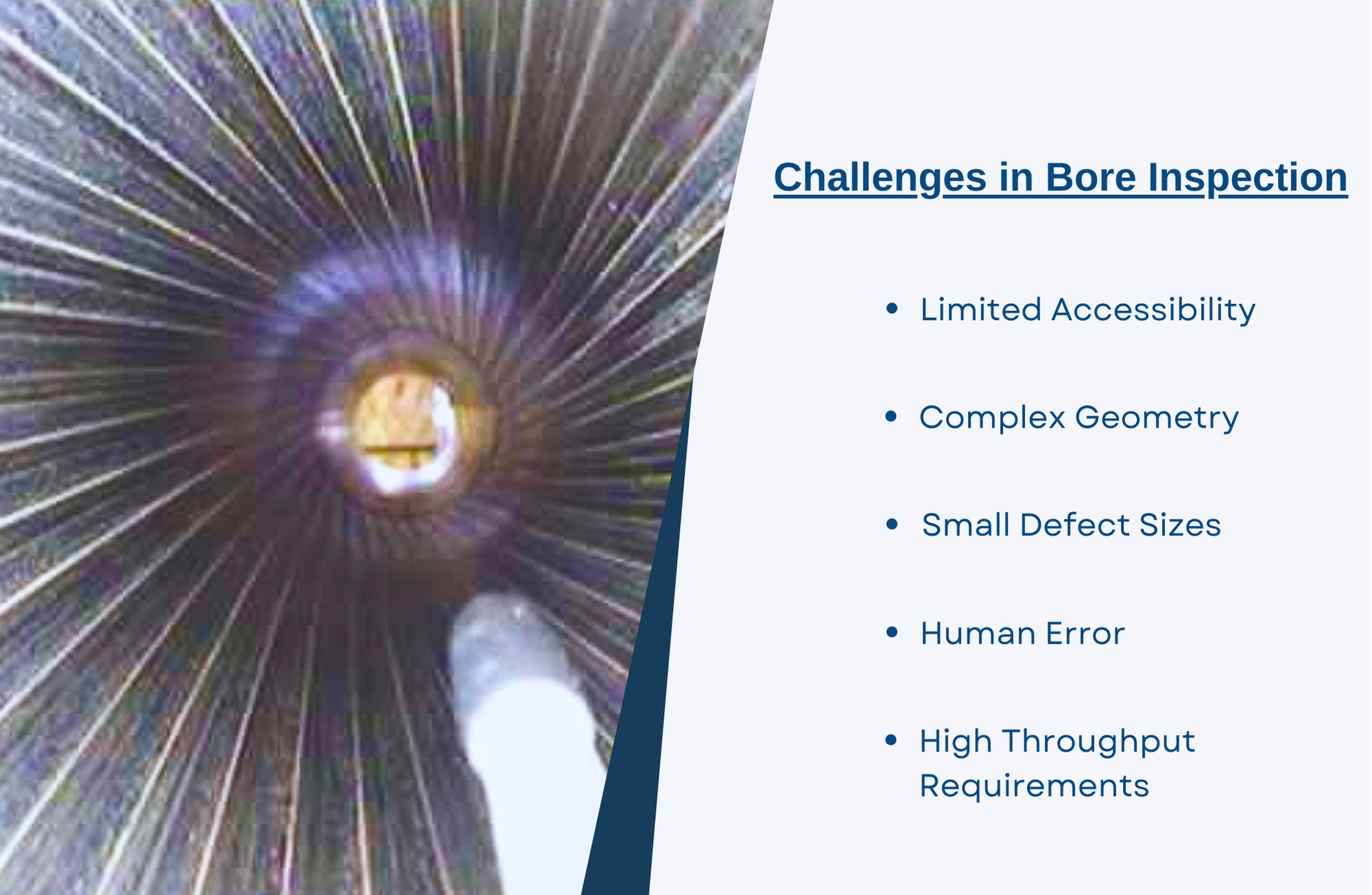

Challenges in Bore Inspection

Inspecting the interior surfaces of bores presents unique challenges:

-

Limited Accessibility:

Bores and narrow cavities are difficult to access, making direct visual inspection impractical. Sometimes, the inner diameter (ID) is 5 mm to 8 mm and traditional machine vision cameras do not work here. -

Complex Geometry:

Irregular or curved internal surfaces often require specialized imaging techniques for effective inspection. -

Small Defect Sizes:

Defects like micro-cracks or surface pitting can be extremely small, requiring high-resolution imaging for detection. -

Human Error:

Manual inspection methods are prone to errors and inconsistencies, especially for repetitive tasks. -

High Throughput Requirements:

In manufacturing environments, the need for rapid inspection of large volumes demands automated and scalable solutions.

Cameras

Borescope cameras are specialized imaging tools designed to inspect confined spaces. Equipped with long, flexible probes and high-resolution optics, these cameras enable close-up views of the internal surfaces of bores. However most of these cameras have bigger sensor size and low resolution which can’t be used for micron level defect detection. To detect micron level defects inside bores, we need special machine vision cameras.

Enhancing Bore Inspection with Machine Vision AI Software

While borescope cameras provide the imaging capability, integrating Intelgic’s Machine Vision AI Software takes bore inspection to the next level by automating defect detection, improving accuracy, and providing actionable insights.

Key Features of Machine Vision AI Software in Bore Inspection

Automated Defect Detection:

The AI software analyzes images or video streams from the borescope camera in real time, identifying defects such as scratches, cracks, and dimensional deviations with high precision.

Pattern Recognition:

Advanced algorithms recognize patterns and anomalies, distinguishing between acceptable and defective surfaces.

Real-Time Feedback:

Immediate feedback allows operators to take corrective actions during the inspection process.

Data Logging and Reporting:

The software generates detailed reports with defect images, and classifications, aiding in traceability and quality assurance.

Customizable Algorithms:

AI models can be trained to detect specific defect types or adhere to particular quality standards based on the application.

Robotic Arm Integration for Bore Inspection Automation

Bore inspection is a critical process in industries such as automotive, aerospace, and manufacturing, where the internal integrity of bores, cylinders, and tubes must meet precise quality standards. At Intelgic, we specialize in fully automating bore inspection by integrating advanced imaging devices with robotic arms, ensuring consistent and uniform imaging of internal surfaces.

How Robotic Arms Enhance Bore Inspection

To achieve precise and reliable imaging, we use robotic arms equipped with cameras and lighting systems. These robotic arms are programmed to perform controlled movements, ensuring every section of the bore is captured with high detail and accuracy.

- Consistent and Uniform Imaging:

The robotic arm maneuvers the imaging device inside the bore, maintaining a stable and uniform position for precise defect detection. - Flexible Inspection Angles:

The arm adjusts to various angles, ensuring all surfaces of the bore are thoroughly inspected, even in hard-to-reach areas. - Integrated Lighting:

Proper illumination is crucial for bore inspection. The robotic arm holds a lighting system optimized to highlight surface details and defects, ensuring high-quality imaging.

Advanced Programming with ROS

Intelgic utilizes the Robot Operating System (ROS) to program robotic arms, enabling precise control and automation:

- Camera Movement:

ROS allows for the smooth and synchronized movement of the camera and lighting system, ensuring seamless imaging throughout the bore. - Automation of Imaging Processes:

ROS-based programming automates critical inspection tasks, reducing human intervention and improving consistency. - Customizable Inspection Workflows:

The system can be tailored to accommodate various bore sizes, materials, and inspection criteria, making it versatile for different applications.

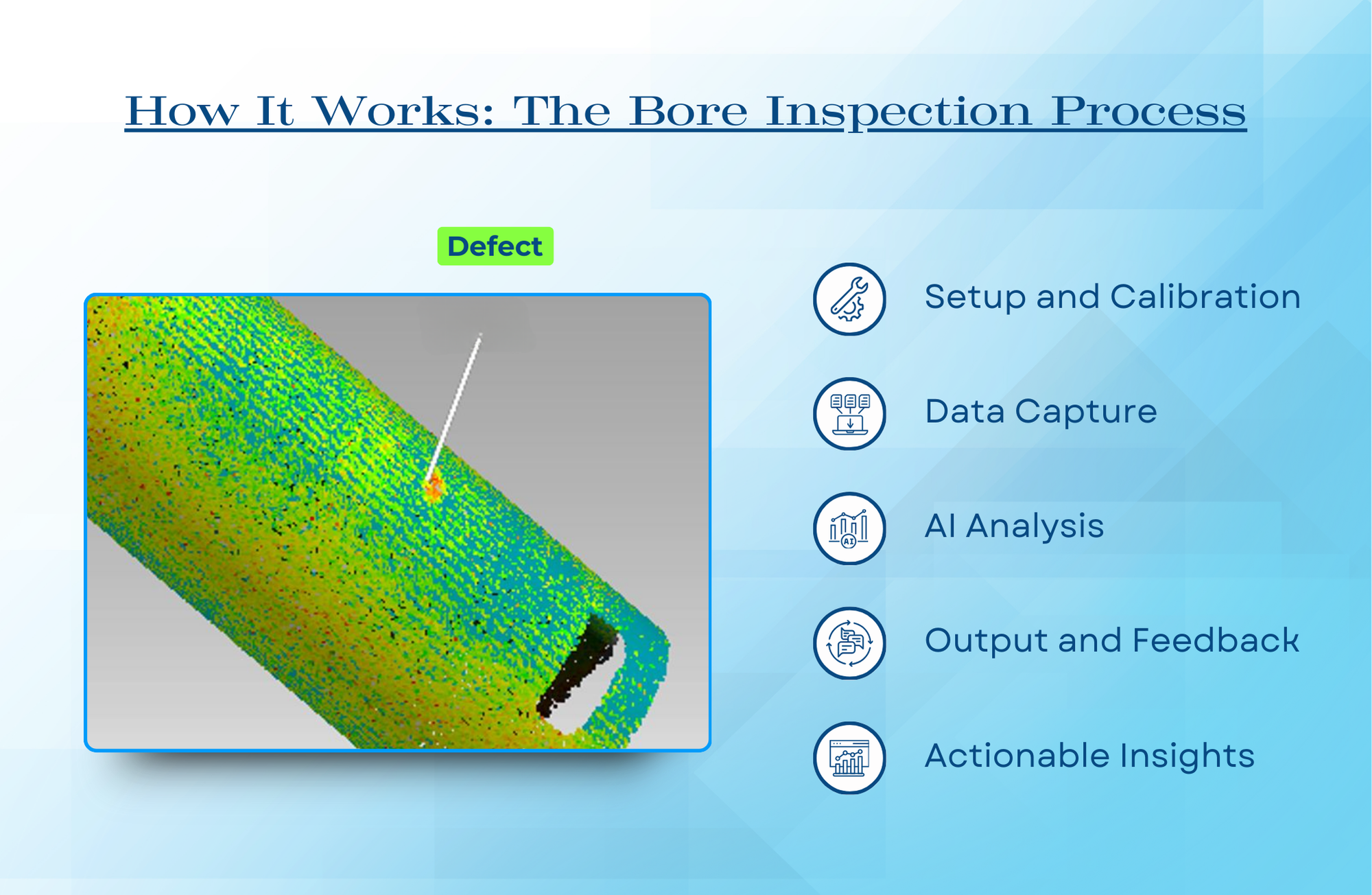

How It Works: The Bore Inspection Process

Setup and Calibration:

-

The borescope camera is inserted into the bore using robotic arms.

-

The Machine Vision AI Software is connected to the camera, and calibration ensures accurate imaging and measurement.

Data Capture:

-

The borescope captures high-resolution images or video of the bore interior.

-

Proper illumination and probe adjustments are made to inspect all surfaces.

AI Analysis:

-

The software processes the images in real time, identifying defects and deviations.

-

Anomalies are flagged, and defect characteristics (size, location, type) are recorded.

Output and Feedback:

-

The results are displayed on a monitor for the operator.

-

Detailed reports are generated for quality control documentation.

Actionable Insights:

-

Manufacturers can use the insights to address defects, refine machining processes, and improve overall quality.

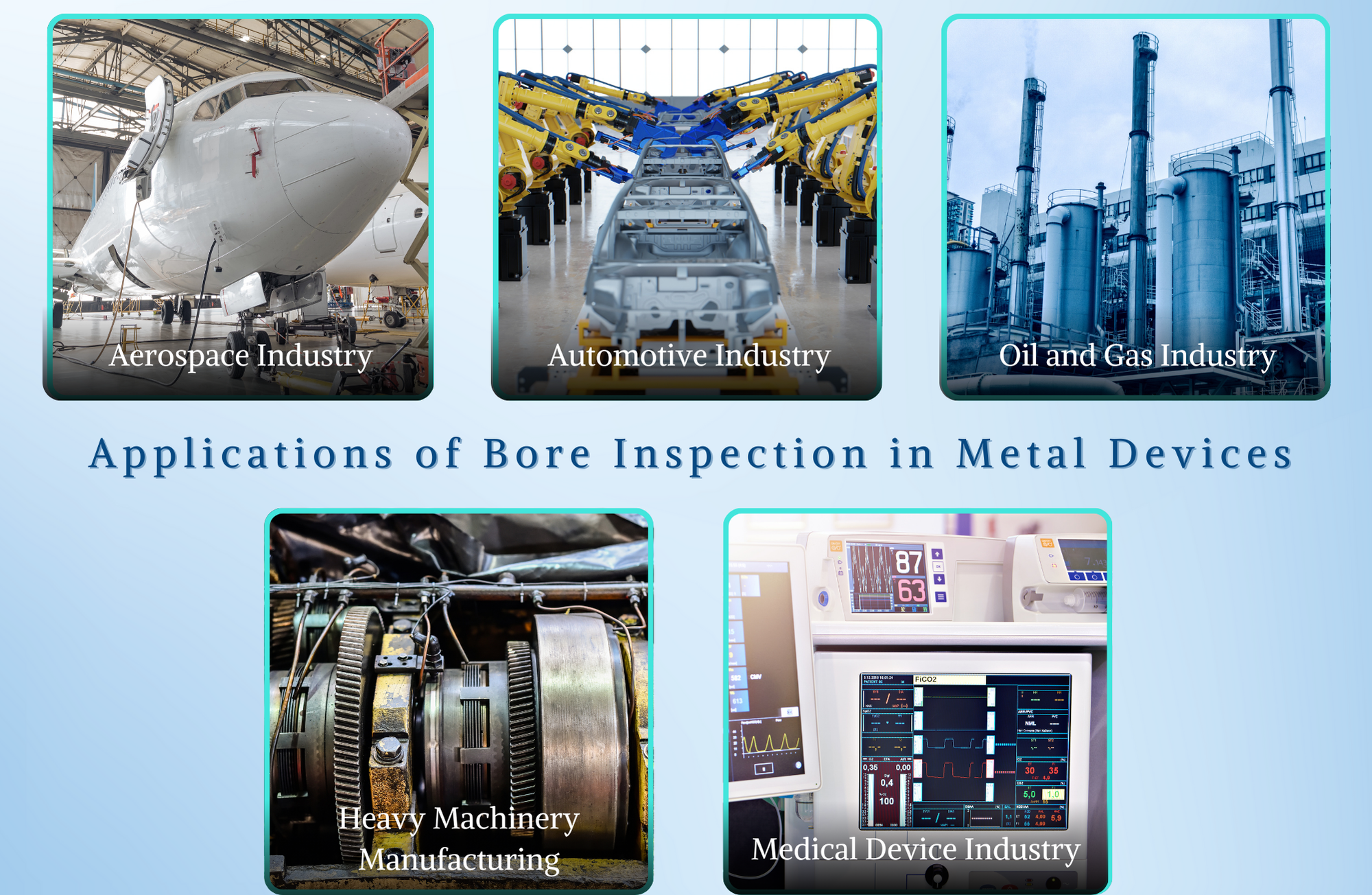

Applications of Bore Inspection in Metal Devices

Aerospace Industry:

Inspection of turbine components, engine cylinders, and precision machined parts to ensure reliability in critical applications.

Automotive Industry:

Examination of engine bores, hydraulic cylinders, and brake system components for manufacturing defects.

Oil and Gas Industry:

Inspection of pipes, valves, and drill components for corrosion, cracks, or wear.

Heavy Machinery Manufacturing:

Quality control of gears, shafts, and large rotating components.

Medical Device Industry:

Verification of precision bores in surgical instruments and implants.

Advantages of AI-Enhanced Bore Inspection

Improved Accuracy:

AI algorithms detect even the smallest defects that might be missed in manual inspections.

Speed and Efficiency:

Automated inspection processes significantly reduce inspection times, enabling high throughput in manufacturing lines.

Consistency:

Unlike human inspectors, AI provides consistent and repeatable results, eliminating subjective errors.

Cost Savings:

Early detection of defects reduces rework, scrap, and downtime, ultimately saving costs.

Traceability:

Comprehensive reports with detailed records ensure traceability and compliance with quality standards.

Complete Bore Inspection Automation

At Intelgic, we provide end-to-end bore inspection automation, integrating robotic arms, imaging devices, lighting systems, and our AI-powered defect detection software.

- Defect Detection and Classification:

The imaging data is processed in real-time by our advanced AI algorithms, detecting defects such as cracks, pitting, or surface irregularities. - Enhanced Efficiency and Accuracy:

Automation eliminates manual errors and significantly reduces inspection time, ensuring reliable and repeatable results. - Scalability:

Our systems can be scaled to handle complex inspection processes for a wide range of bore sizes and production volumes.

Bore inspection using Machine Vision AI Software and borescope cameras is revolutionizing quality control in industries requiring precision and reliability. By combining the versatility of borescope cameras with the analytical power of AI, manufacturers can achieve unparalleled accuracy, efficiency, and traceability. This approach not only enhances product quality but also optimizes production processes, making it a cornerstone of modern manufacturing.

As the technology evolves, its potential applications and benefits will only expand, solidifying its role as an essential tool in high-precision industries.