Digital Quality Certificate

Proof of Quality. Validation for Warranty. Foundation for Zero-Defects Manufacturing.

Book a call

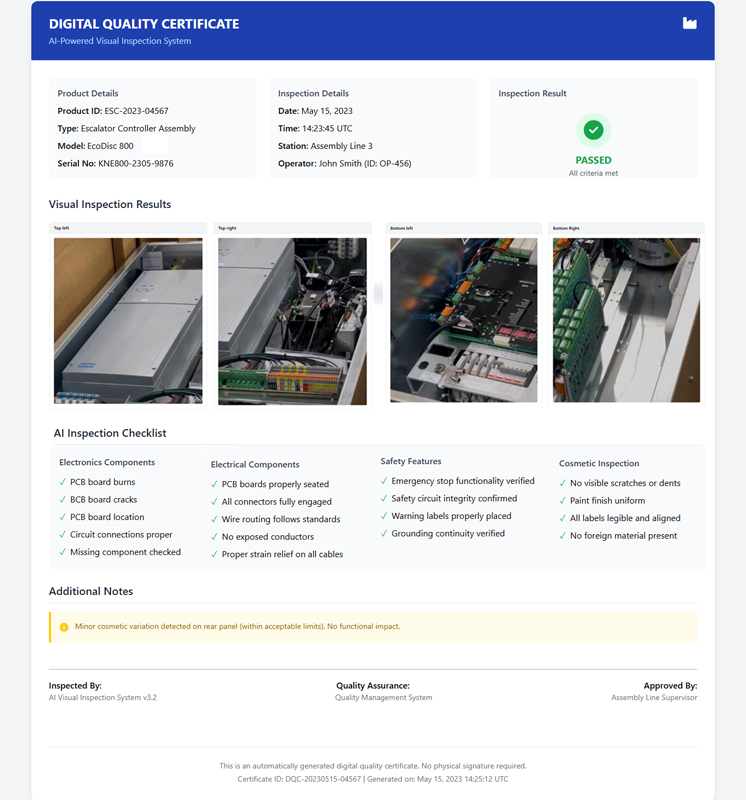

A Digital Quality Certificate (DQC) is an automatically generated certificate issued by Intelgic's inspection system for every product that passes inspection. "Pass" or "Fail" is determined strictly by the acceptance criteria configured in the inspection recipe.

The DQC serves as machine-generated proof of quality, confirming the unit was verified by Intelgic's calibrated machine-vision system.

Defect detection / quality inspection (end-of-line and in-process)

Assembly line monitoring (component presence, orientation, fastening)

SOP monitoring (step-by-step compliance verification)

All Intelgic automated inspection solutions configured for your products

Accountability

Traceability

Compliance

More than a record — it is a verifiable proof of quality that strengthens trust, accountability, and compliance.

A DQC can be issued directly to end customers as documented proof that the product has passed machine vision-based quality checks.

Every inspection parameter and result is logged, enabling manufacturers to revisit detailed records for any product at any time.

DQCs provide undeniable evidence to validate or reject warranty claims quickly and fairly.

Complete, certificate-based inspection logs simplify regulatory and customer audits.

Detailed inspection data holds suppliers responsible for material or component quality, improving supply chain reliability.

With DQC, manufacturers move from traditional quality assurance to a transparent, data-driven system.

Cameras and sensors collect images at inspection or assembly stages.

Intelgic's AI software checks defects, missing components, SOP compliance, and dimensions.

Products are marked Pass/Fail based on acceptance criteria.

DQC is created for PASS units, storing annotated images, results, and timestamps.

Certificates are securely stored (cloud or on-premise) and retrievable by serial, batch, or RMA number.

DQCs are used for warranty claims, audits, or supplier negotiations.

Trend detection

KPI dashboards

Defect mapping

Warranty claim traceability

Implementing Intelgic's DQC system delivers measurable results

↓ 25–40% with evidence-based validation

>99% by preventing errors during assembly

↓ 30–50% through data-driven CAPA

↓ 60–80% prep time with instant certificate retrieval

DQC applies to any industry where quality and traceability matter

Harnesses, modules, ECUs, lamps and other critical components that require strict quality control.

SMT, subassemblies, PCB boards where component placement and soldering quality are critical.

Control panels, safety systems that must meet strict operational and safety standards.

Compliance-ready inspection records for devices that impact patient health and safety.

Wiring, seals, assemblies where quality impacts product longevity and safety.

Controllers, safety assemblies where failure could have catastrophic consequences.

Yes, every product that passes inspection according to acceptance criteria receives a DQC.

Yes, DQCs can be shared with end customers as proof of quality checks. Sensitive data can be redacted if needed.

The certificate provides visual and data evidence of inspection at shipment. This helps validate or reject claims quickly and fairly.

You can choose cloud-based or on-premise storage. Both are secure, encrypted, and accessible by authorized personnel.

Yes, Intelgic's system integrates seamlessly with MES, ERP, and QMS systems via API.

Retention is configurable — typically 3–10 years depending on compliance requirements.

Yes. Each DQC is cryptographically signed and audit-tracked to ensure authenticity.

Discover how Intelgic's Digital Quality Certificate can revolutionize your manufacturing quality control.

©2025 Intelgic Inc. All Rights Reserved.