Customized Quality Inspection System

Book a call

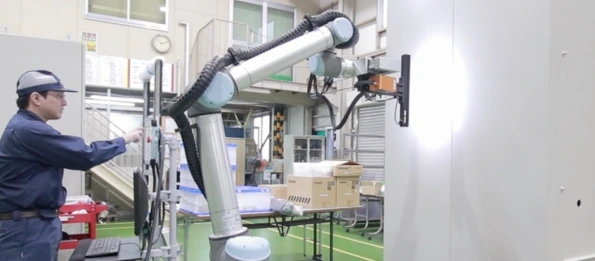

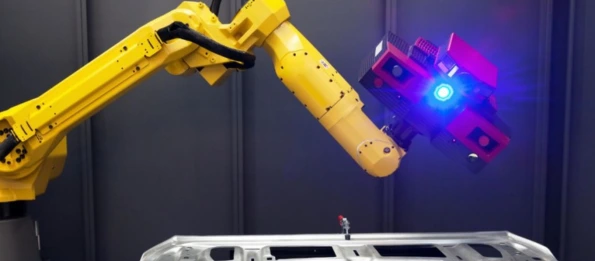

In critical and complex manufacturing environments, ensuring product quality is paramount. Off-the-shelf inspection solutions often fall short when dealing with complex processes, diverse product shapes and sizes, or stringent quality standards. That’s why we design and build Customized Inspection Systems tailored specifically for demanding inspection needs. Our systems incorporate advanced electromechanical components, high-precision imaging systems, cutting-edge AI software, and robotic automation, creating a robust solution that integrates seamlessly into your production line.

Our inspection systems are engineered for excellence, incorporating multiple essential components to ensure comprehensive and accurate inspection:

We follow a structured approach to design and implement the ideal quality control solution for your manufacturing needs:

In-Depth Consultation and Analysis

In-Depth Consultation and Analysis System Design and Engineering

System Design and Engineering Development of Electromechanical Components

Development of Electromechanical Components Vision System Integration

Vision System Integration Robotic Automation for Seamless Operation

Robotic Automation for Seamless Operation Software and Control System Integration

Software and Control System Integration Testing and Validation

Testing and Validation Implementation and Ongoing Support

Implementation and Ongoing SupportA customized quality control system offers unparalleled precision and adaptability, ensuring your products meet the highest quality standards without compromising on production efficiency. With a customized solution, you gain:

A customized inspection system is more than an investment in quality—it's a commitment to excellence in manufacturing. Our tailored solutions ensure that every product meets the highest standards, providing you with a competitive edge in today’s quality-driven market.

Contact us today to discuss your specific quality control needs and learn how we can create a custom inspection solution that integrates seamlessly into your production line, delivering precise, efficient, and automated quality control. Let us help you elevate your manufacturing quality with a solution designed just for you.

©2025 Intelgic Inc. All Rights Reserved.