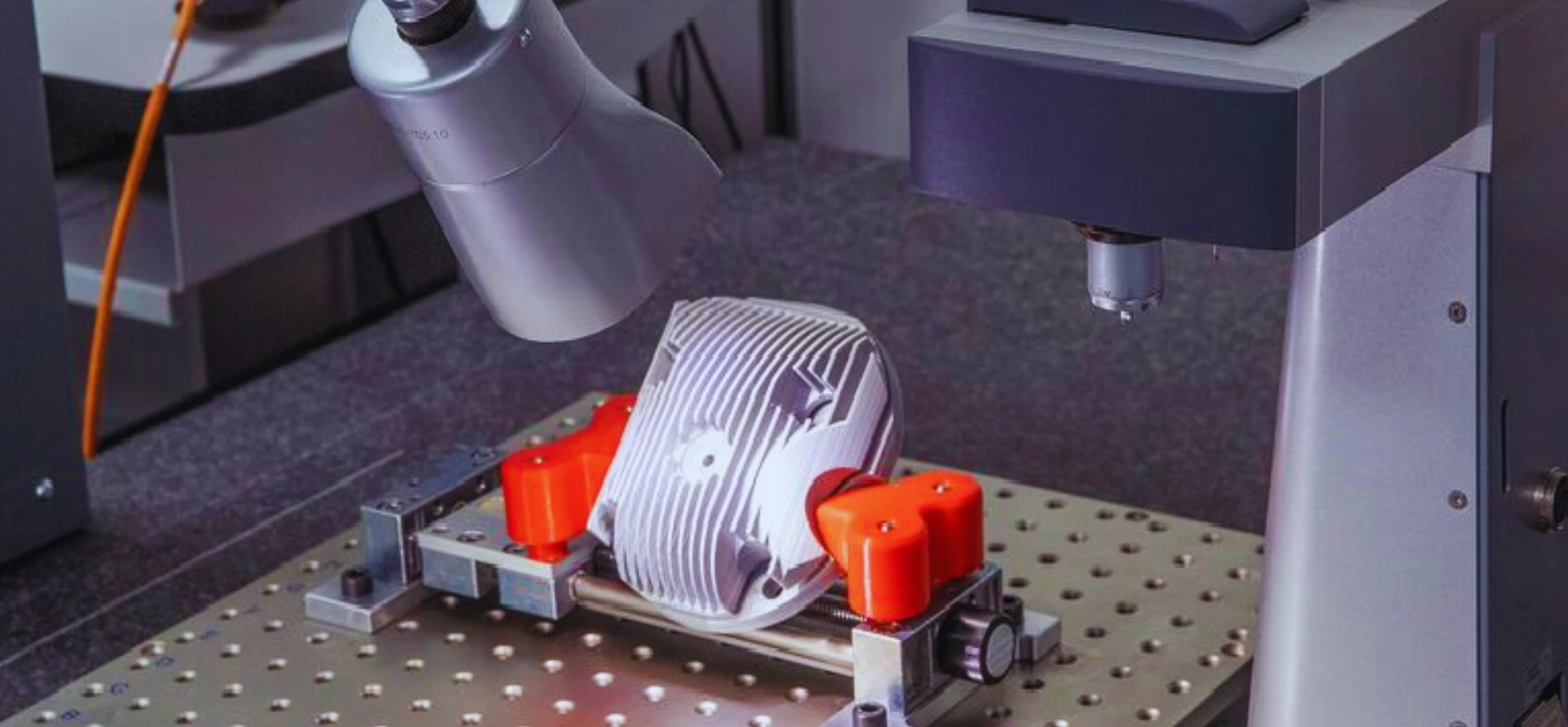

Automate measurement and quality inspection process anywhere in the production lines using AI driven non-contact measurement systems

Book a call

As industries push for higher accuracy and efficiency, traditional contact measurement methods often fall short in fast-paced environments where precision and speed are critical. Intelgic's Non-Contact Measurement system, powered by advanced machine vision and AI, provides an innovative solution that eliminates physical contact with parts, ensuring that even delicate and complex components are measured with unparalleled precision.

Non-contact measurement systems offer several advantages over traditional contact-based methods

Delicate parts like medical devices, electronics, or soft materials can be measured without risk of deformation or damage.

Ideal for high-volume production lines, as parts can be inspected in real-time without stopping or slowing down the proces

Removes human error and variability, offering consistent and repeatable results for every part inspected.

Capable of accurately measuring complex 3D shapes, angles, and features that would be difficult or impossible with contact-based tools.

Our non-contact measurement system uses high-resolution cameras and AI-powered algorithms to capture precise images of the object being measured. Advanced image processing software then analyzes these images to determine critical dimensions such as length, width, height, diameter, depth, and even surface profile. The system can be fully automated to integrate seamlessly into existing production lines, providing real-time measurement data without interrupting the flow.

Using advanced optics and sensors, our system delivers micron-level precision. The system can handle measurements for small, intricate parts as well as large industrial components with ease.

With real-time data processing, measurements are taken instantly as parts move along the production line, providing immediate feedback on dimension compliance.

Capable of capturing both 2D and 3D measurements, our system offers comprehensive analysis of objects, including surface flatness, diameter, height, depth, and more. This ensures that every aspect of a part is measured to specification.

Ideal for fragile or sensitive materials like glass, plastic, rubber, and soft metals, our system ensures that measurements are conducted without altering or damaging the product.

Our non-contact measurement system is adaptable to a wide variety of industries and part geometries. Whether measuring smooth surfaces, sharp edges, or intricate patterns, the system can be customized to meet specific inspection needs.

All measurement data is logged and stored for traceability and compliance. Detailed reports are generated in real time, providing actionable insights into product quality and ensuring adherence to industry standards.

Non-contact measurement of critical components like brake rotors, drive shafts, pistons, and gears, ensuring optimal performance and safety without damaging the parts.

Precision measurement of turbine blades, fuselage sections, and other components where accuracy is paramount, without introducing the risk of contamination or deformation.

Inspection of delicate devices such as stents, catheters, and surgical tools, where contact-based measurement would risk damaging or contaminating the product.

Measurement of printed circuit boards (PCBs), connectors, and other electronic components, ensuring precise alignment and dimensional accuracy without impacting sensitive components.

Accurate measurement of metal parts, including tubes, rods, and sheets, ensuring that dimensions meet specifications without damaging or altering the surface.

All measurement data is logged and stored for traceability and compliance. Detailed reports are generated in real time, providing actionable insights into product quality and ensuring adherence to industry standards.

Transform your manufacturing process with measurable advantages that drive efficiency and quality.

Automate measurement processes and increase throughput with faster production cycles.

Real-time detection of dimensional deviations for immediate corrective actions.

Prevent measurement errors and improve process control to reduce material waste.

Easily integrate with PLC, SCADA, ERP, MES, and other manufacturing systems.

Understand the key differences between traditional and modern measurement approaches.

©2025 Intelgic Inc. All Rights Reserved.