Automated Optical Inspection (AOI) Systems

Automate your inspection process using cutting edge AI powered AOI system

systems_banner.png)

In today’s competitive manufacturing landscape, ensuring flawless product quality is critical. Intelgic, a leader in Automated Optical Inspection (AOI) systems, designs and develops custom AOI solutions tailored to the unique needs of manufacturers. By combining cutting-edge imaging devices, anomaly detection AI software, Live Vision robust controllers, and custom electromechanical systems, Intelgic delivers fully automated inspection systems that ensure precision, efficiency, and reliability. Intelgic’s AOI systems automate quality control, enabling manufacturers to:

Every manufacturing process is unique—different products, varied workflows, and distinct environmental conditions make each operation stand apart. For complete quality control automation, a custom AOI solution is essential—one that is tailored to your specific products, processes, and environment. Intelgic specializes in designing and developing custom Automated Optical Inspection systems designed to integrate seamlessly into your production line. Our solutions are crafted to meet the unique demands of your manufacturing setup, ensuring they align perfectly with your product requirements, operational processes, and quality standards.

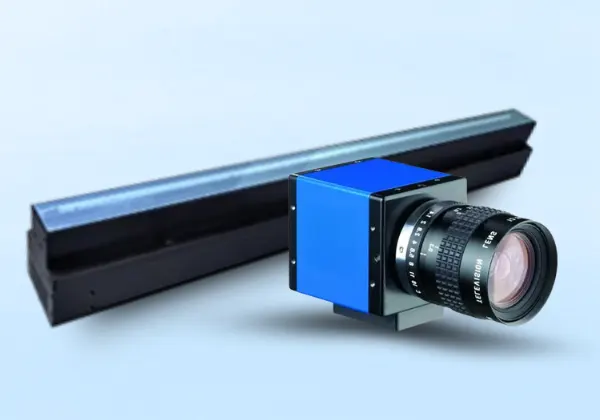

Intelgic offers a range of high-resolution imaging devices to capture detailed visuals for accurate defect detection. We choose and customize the best imaging solution based on factors like material type, surface texture, defect size, and inspection speed.

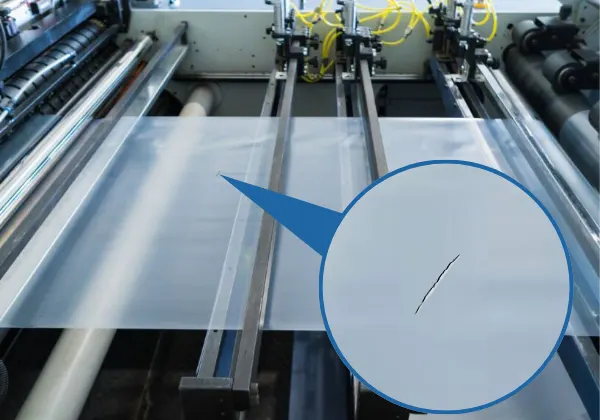

Ideal for inspecting continuous surfaces like films, foils, textiles, and metal sheets. CIS modules are customizable in length to match the inspection area, ensuring consistent imaging.

Machine Vision Cameras:High-resolution cameras for inspecting large parts, components, or assemblies. These cameras are versatile and adaptable for a wide range of inspection tasks.

Specialized Cameras:Compact cameras designed for inspecting hard-to-reach areas, such as the inner walls of tubes or confined spaces.

At the heart of Intelgic’s AOI systems is our AI-powered anomaly detection software, Live Vision, designed to identify even the smallest defects with precision.

Trained to detect anomalies like scratches, cracks, dents, discoloration, and dimensional irregularities.

Customizable AI Models:Tailored to your specific products, ensuring high detection accuracy and minimizing false positives.

Real-Time Processing:Analyzes video streams from imaging devices instantly, providing immediate feedback and actionable insights.

Comprehensive Reporting:Generates detailed defect reports, including defect type, location, and images, enabling traceability and process optimization.

Intelgic’s AOI systems are built with custom electromechanical components to automate material handling, positioning, and inspection processes.

We provide custom conveyor systems that ensure consistent movement of parts under imaging devices for accurate inspection.

Tailored Designs:Systems are designed to accommodate product size, shape, and production speed, ensuring seamless integration with your existing manufacturing line.

Mounting System:We provide necessary mounting system for imaging, lighting and other machine vision components.

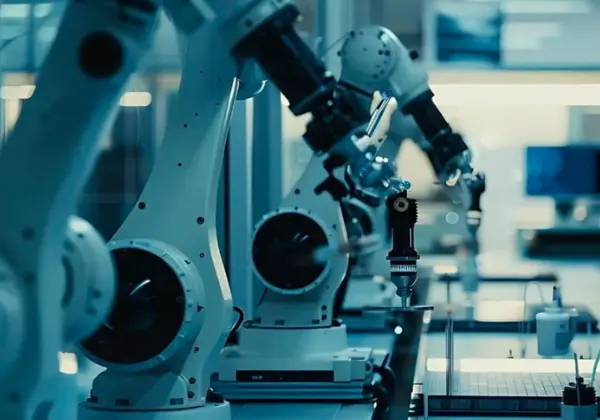

For complete inspection automation, a custom robotic system is often essential to address complex inspection requirements and streamline processes. Intelgic designs and integrates custom robotic arms and systems into its AOI solutions, enhancing automation and efficiency.

Robotic arms can mark detected defects on products with precision, enabling clear identification for rework or sorting.

Camera Movement for Complex Inspections:In cases where the inspection process involves irregular or multi-dimensional surfaces, robotic systems ensure uniform movement of cameras, allowing detailed imaging and thorough inspection.

Product Handling for Imaging:Robotic systems manage the uniform movement of products, ensuring optimal alignment and positioning for accurate imaging.

Intelgic’s AOI systems include powerful controllers that manage the integration of imaging devices, AI software, and electromechanical systems.

Ensures smooth coordination between the inspection components and production line.

Flexible Interfaces:Compatible with various industrial systems and protocols for easy integration into existing setups.

At the heart of Intelgic’s Automated Optical Inspection (AOI) systems is its state-of-the-art AI-powered defect detection technology, engineered to deliver unparalleled precision and efficiency. Intelgic’s state of the art AI is specially designed to detect defects in various products, processes, and materials, making it a standout solution in the manufacturing industry.

Intelgic’s success lies in its array of advanced AI algorithms, which are carefully selected and customized to suit the specific requirements of each inspection process. Depending on factors such as the product type, inspection process, material characteristics, and defect size, Intelgic develops and deploys the most effective AI model for your manufacturing needs.

Detecting defects at the micron level on fast-moving sheets or reflective materials is a complex challenge that requires precision, speed, and adaptability. Intelgic specializes in providing customized solutions for such demanding inspection requirements, ensuring flawless quality control for manufacturers dealing with continuous sheet materials like films, foils, textiles, and coated surfaces.

Intelgic offers tailored imaging systems based on the specific dimensions and properties of your sheet materials:

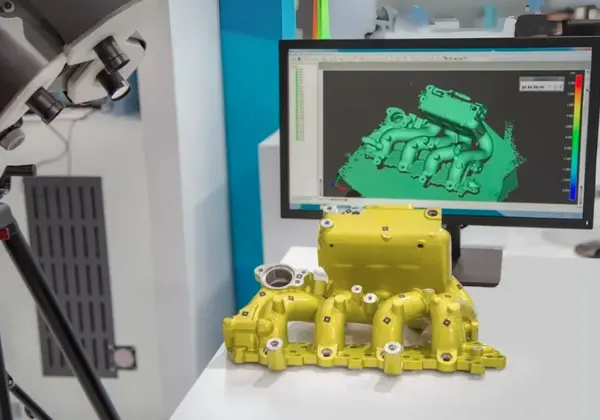

Inspecting large parts, such as automotive components, aerospace structures, or heavy machinery, requires precision, adaptability, and scalability. Intelgic’s Automated Optical Inspection (AOI) systems are specifically designed to address the challenges associated with large part inspection, ensuring comprehensive quality control for complex and oversized products.

Large parts present unique inspection challenges, including:

Intelgic provides customized AOI systems tailored to the specific needs of large part inspection, ensuring accuracy, efficiency, and scalability.

Intelgic’s electromechanical systems ensure efficient and consistent handling of large parts during inspection:

Intelgic’s Live Vision AI software brings advanced capabilities to large part inspection:

©2025 Intelgic Inc. All Rights Reserved.