Multilayer Ceramic Capacitors (MLCC) – Automated Visual Inspection with AI

MLCCs are tiny, brittle, and process-sensitive. Cosmetic flaws often correlate with latent reliability risks, while the smallest handling nick can become a catastrophic crack after reflow.

Chips as small as 0201/0402 (and smaller), millions per day.

Micro-chipping and micro-cracks are hard to see, easy to miss.

Matte vs. glossy end terminations, plating tone changes.

Green tape punching, stacking, lamination, dicing, tumble deburr, plating, marking, and packaging each introduce unique defects.

Inspection must match high-speed singulation and tape-and-reel rates without false rejects.

Note: Electrical parameters (capacitance/ESR/DF/IR) are typically verified by E-test/ATE. Intelgic can interface with those stations and correlate visual-to-electrical outcomes for richer SPC.

20–65 MP industrial sensors, global shutter; optional line-scan for continuous web

Telecentric for metrology; long-WD macro for TnR; motorized focus for thickness steps

Vibration-isolated stages, fiducial-based alignment, flip modules for dual-side viewing

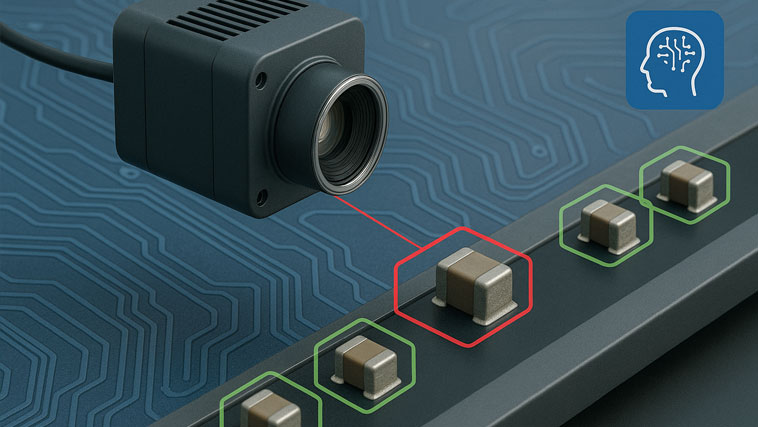

Intelligent defect detection and classification powered by machine learning

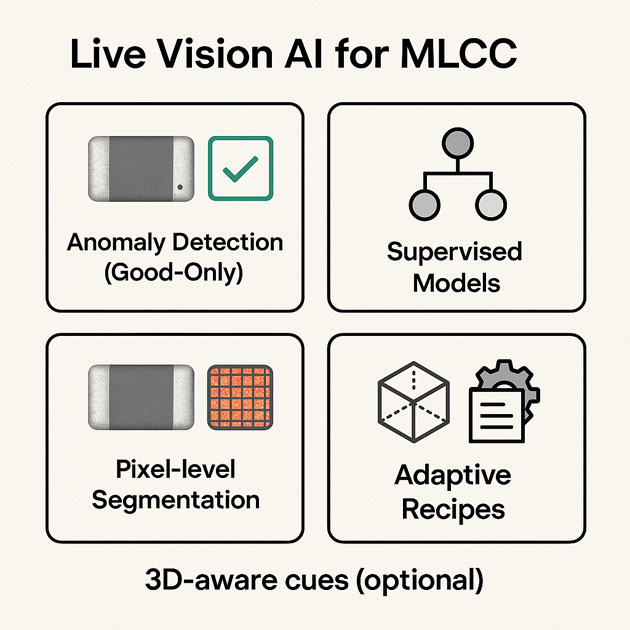

Learn “golden appearance” of ceramic and plating; flag novel defects without exhaustive labeling.

Classify chips (OK, minor chip, severe chip, crack, plating short, porosity, contamination, etc.).

Measure crack length/edge chip area in µm; compute wrap/coverage metrics.

Multi-angle reflectance or height proxies for subtle bevel defects.

One station handles multiple sizes/series—swap recipes in seconds; automatic scale re-calibration with a grid target.

L/W/T tolerance in µm; bevel min/max; wrap length %

Max chip area (µm²) per edge; crack length/angle thresholds

Minimum coverage; maximum porosity count/area; blister detection confidence

Particle size/contrast thresholds; stain/mark acceptance windows

OK / Rework / Reject with IPC-like severity bands (customizable)

All measurements are logged per serial/lot and bound to DQC (Digital Quality Certificate).

Tuned to match singulation and TnR lines (multi-camera parallelization supported)

: Real-time PASS/FAIL with reject chute, marker, or diverter outputs

OPC-UA / MQTT / REST / SQL; barcode/QR lot binding; ATE & MES/ERP hooks

Operator, QE, Admin; recipe version control; audit trail

Images, masks, metrics, decision, recipe version, operator/line ID, timestamps

Pareto of top defects, FP/FR trend, heatmaps, SPC charts, OEE

Link visual defects to upstream steps (lamination, sinter, plate, pack)

Digitally signed certificate for every shipped reel/tray

Detect cracks & chips that drive field failures with unprecedented precision

Learned normal modeling and robust lighting reduce false positive rates

Reduce warranty exposure and improve overall cost of quality

Handle multiple sizes/series with quick recipe switching

Digital Quality Certificate (DQC) for compliance and customer audits

For internal electrode faults, X-ray is typical. Intelgic focuses on external visual and metrology; we can integrate X-ray results into the same dashboard/DQC if available.

Yes—telecentric optics + recipe scaling and auto-calibration support a wide range of sizes.

Stage & scale calibration with traceable targets; periodic checks; recipe-bound scale factors; GR&R reporting.

Cross-polarized coaxial + darkfield blends and exposure bracketing; AI trained across illumination variants.

©2025 Intelgic Inc. All Rights Reserved.