Industrial Lighting for Machine Vision Imaging

Precision Illumination for Reliable AI-Driven Inspection

In industrial imaging, lighting is everything. The quality, direction, intensity, and uniformity of light directly determine how well a machine vision system can detect features, anomalies, and dimensional variations in a product. At Intelgic, we engineer specialized lighting systems tailored for high-performance machine vision and AI-based image processing applications.

From shiny metal surfaces to transparent medical components, proper illumination unveils critical features that raw camera resolution alone cannot. Lighting is not just an accessory—it is an integral part of the imaging system design, ensuring accuracy, repeatability, and robustness in real-world inspection environments.

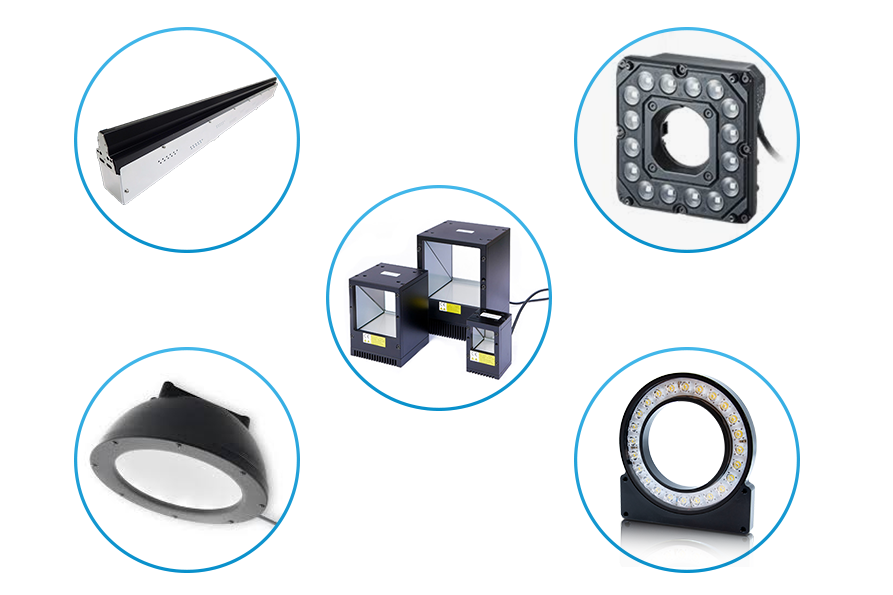

Intelgic offers a comprehensive range of industrial lighting solutions designed for both line scan and area scan imaging setups. Whether your application demands intense directional lighting, uniform diffused lighting, or shadowless illumination, we select or custom-configure the optimal light source to match your imaging goals.

In high-precision machine vision systems, lighting control is just as important as the light source itself. Lighting conditions must adapt dynamically to variations in product types, inspection stages, and imaging environments. Intelgic’s advanced lighting controllers ensure precise regulation of light intensity, duration, timing, and synchronization—enabling consistent, high-quality image acquisition in every frame.

Adjust light brightness in real-time to optimize contrast, reduce overexposure, and improve defect visibility for different surfaces or materials.

Synchronize short bursts of high-intensity light with camera exposure times for capturing fast-moving objects or minimizing motion blur.

Drive multiple lighting zones (e.g., top light, backlight, side light) independently from one controller, enabling programmable lighting profiles.

Coordinate with cameras, encoders, and PLCs for precise timing control—especially critical in line scan or high-speed conveyor systems.

Support for TTL, RS-232, Ethernet, or industrial protocols allows seamless integration with automation systems and centralized control platforms.

Intelligent monitoring systems protect LEDs and equipment from damage due to electrical or thermal stress, ensuring long life and reliability.

Deliver stable illumination for applications requiring continuous lighting.

Provide high-intensity, short-duration light pulses synchronized with image capture.

Enable user-defined lighting profiles and sequencing for multi-stage inspections.

At Intelgic, our lighting controllers are designed to work in harmony with our AI-driven image processing software and vision hardware. By integrating lighting control into the AI workflow, we can automatically adjust illumination based on live feedback—maximizing image clarity and detection accuracy in real-time.

©2025 Intelgic Inc. All Rights Reserved.