Transparent materials introduce unique inspection challenges that conventional systems often miss.

Defects can "disappear" as light passes through unless shaped correctly.

Specular surfaces hide fine scratches and sleeks from detection.

Minimal difference between defect and background reduces detectability.

Double images distort edges and surface features during inspection.

Application-specific lighting geometry matched to each part type.

Cross-polarization to suppress glare and reveal faint scratches.

Adaptive thresholds and super-resolution for transparent surfaces.

Detect <10µm scratches and pits with specialized optics.

Low-angle oblique lighting + dark-field elevates grazing scratches while suppressing glare.

Telecentric backlighting creates crisp silhouettes for edge chips and inclusions.

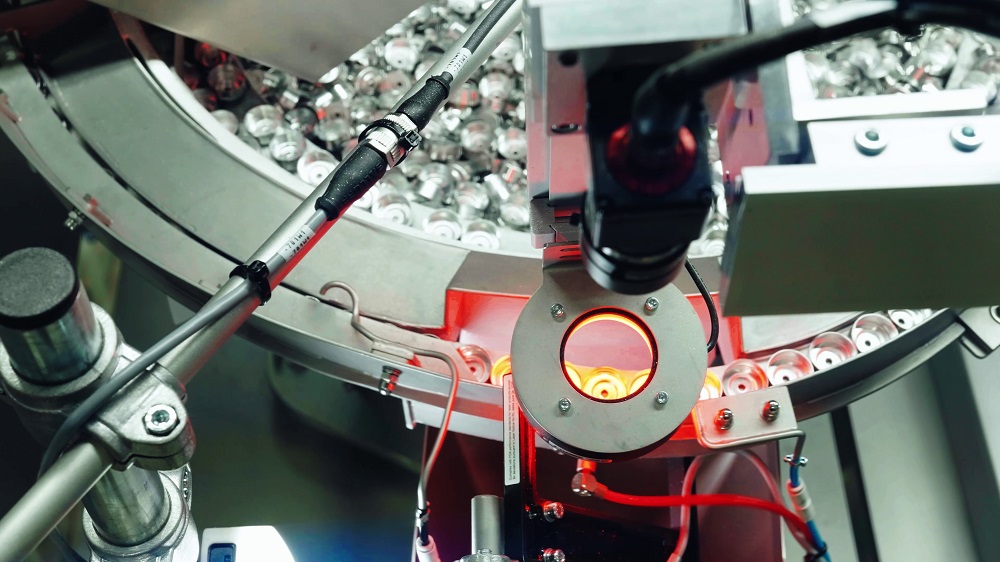

Inner-wall dark-field, mouth/neck coaxial, with view unwrapping for cylindrical bodies.

Our turnkey solution combines precision hardware with intelligent software for comprehensive defect detection.

High-resolution area-scan (12–65 MP) and line-scan (2k–8k) cameras with telecentric lenses and liquid lens autofocus.

low-angle light or backlights with dome/coaxial, polarization kits.

Encoder-synced conveyors, rotary stages for 360° scans, multi-axis robotic rails for large panes.

Recipe-based inspection per SKU with defect libraries

Multi-view defect fusion and 3D unwrapping

Measurement tools for edge radius, thickness, and angles

OCR/OCV for batch codes and laser-etched marks

Real-time pass/fail with explainable defect snapshots

For every PASS part, the system issues a traceable Digital Quality Certificate (DQC) with:

Our systems are designed for diverse transparent glass products across multiple industries.

Smartphone/tablet cover glass, architectural lites, tempered glass, and appliance panels.

Windshields, sidelites, backlites with frit & logo inspection, edge chips/cracks detection.

Plano/spherical lenses, camera optics, AR/VR components, glass wafers with sub-micron defects.

Bottles, vials, ampoules, syringes with mouth/neck, body, and base inspection capabilities.

Slides, cuvettes, pipettes, test tubes with cleanliness and defect screening.

Display glass, optical filters, laser components with stringent quality requirements.

High-speed inspection with microscopic defect detection capabilities.

Scratches/pits to <10 µm (flat glass & lenses), bubbles ≥30–50 µm; edge chips ≥20 µm length.

Up to 80 m/min on line-scan sheet inspection; 240–600 parts/min on vial/bottle turrets.

Telecentric optics enable sub-pixel metrology with automatic calibration routines.

Industrial PC with local server for real-time control and data residency.

Centralized Digital Quality Certificates and cross-plant benchmarking.

Operator app for spot checks and re-inspection with guided capture.

Answers to common questions about our transparent glass inspection systems.

By designing lighting geometry to the part: low-angle oblique for flat glass and backlighting for small transparent parts like lenses, then augmenting with coaxial/dark-field and polarization.

Yes. Dark-field and backlight reveal surface sleeks and sub-surface inclusions like bubbles/seeds. For thicker parts, multi-angle lighting improves detectability.

We use rotary inspection and view-unwrapping to flatten cylindrical images for consistent detection, plus targeted lighting to highlight embossing defects.

Yes. OCR/OCV verifies lot, batch, and expiry codes, and checks presence/quality of brand and regulatory marks.

Per-part DQC, daily/shift reports, defect Pareto, and audit logs with user actions. FDA/ISO 13485 documentation available for medical applications.

Yes. Choose based on data governance and latency needs; hybrid is also supported with local real-time control and cloud analytics.

Ready to eliminate returns from hidden chips and micro‑scratches? Schedule a feasibility study with Intelgic to benchmark your parts and line speeds.

©2025 Intelgic Inc. All Rights Reserved.