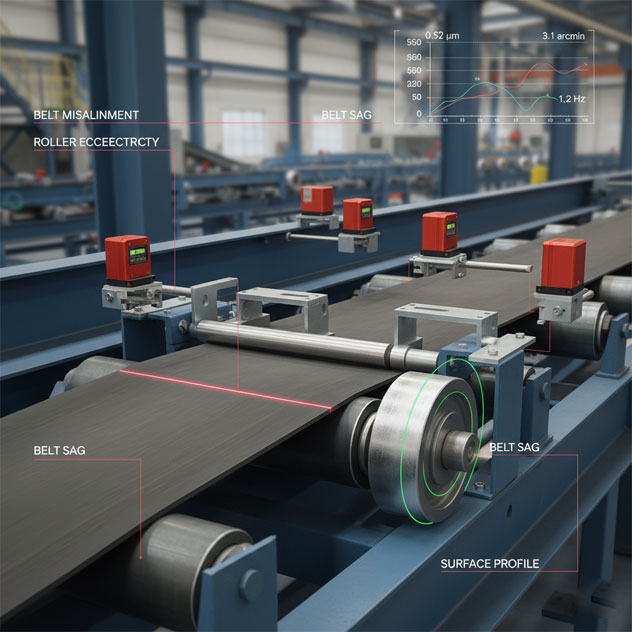

Real-time alerts to the maintenance team before major breakdowns or accidents.

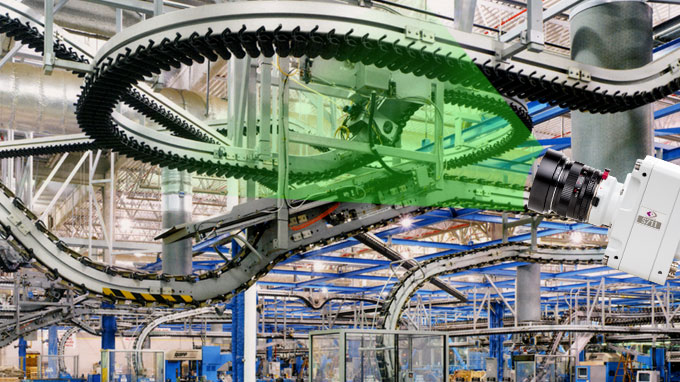

No manual walk‑downs and get early symptoms—belt edge fray, roller eccentricity, cracks, misalignments, carryback, and skew that silently grows into catastrophic failure. Reactive fixes cause stoppages, safety risks, and spiraling costs.

Intelgic turns your conveyors into self‑reporting assets that reveal issues before they break.

Intelgic’s Live Vision AI software processes these images frame by frame to identify anomalies automatically and classify the type of defect detected.