Robotic Inspection System for Complex Automotive Parts

Automate. Inspect. Assure Quality.

High-precision robotic inspection for complex-shaped automotive parts using machine vision and AI.

Book a call

Automotive components come in all shapes and sizes—metallic, plastic, painted, assembled—and they’re getting more intricate with every new vehicle model. Manual inspection simply can’t keep up with the volume, complexity, or accuracy demands.

Intelgic’s Robotic Inspection System is engineered for high-speed, high-precision inspection of complex automotive parts using a combination of robotics, industrial imaging, and AI-powered defect detection.

We deliver fully automated, turnkey systems that detect defects, verify dimensions, validate assembly, and generate digital quality certificates in real-time.

Intelgic’s solution is built for diverse and complex parts, including.

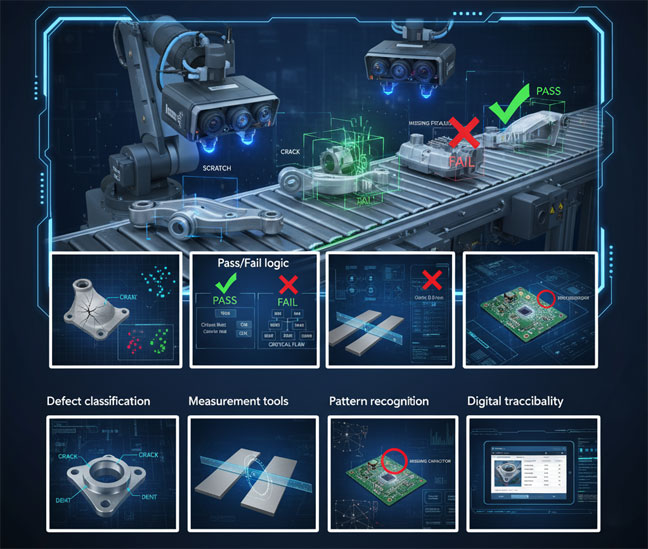

At the core of our system is Live Vision AI, Intelgic’s proprietary machine vision software. It enables

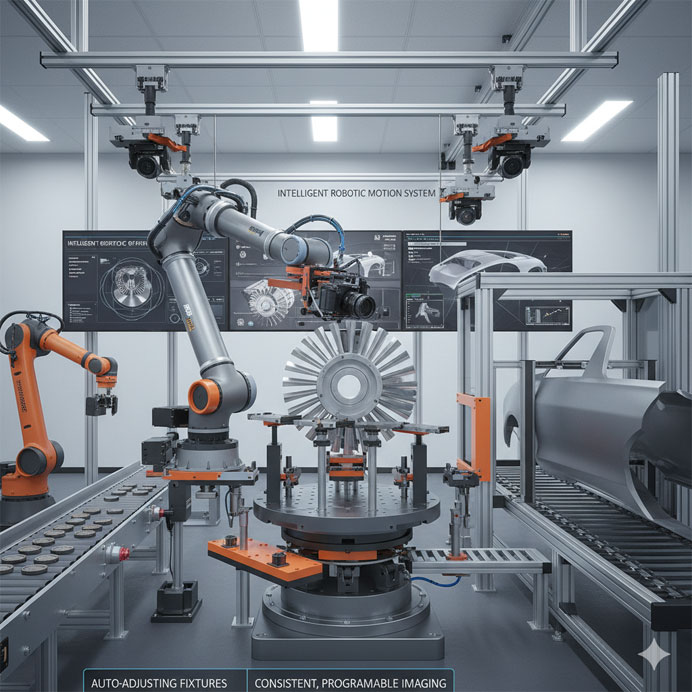

We integrate SCARA, 6-axis robotic arms, cartesian systems, or motorized stages depending on the application.

Whether your part is small and intricate or large and bulky, our robotic platforms ensure consistent, programmable, and repeatable imaging.

Lighting and lensing are customized for each part type and material finish.

Intelgic systems support real-time, inline inspection, integrated directly into your production line.

Automated defect detection during manufacturing

PLC integration to trigger alerts or stop production

Digital Quality Certificate (DQC) generated for each part

Cloud-connected dashboard for analytics and historical reports

Our software provides detailed inspection logs, annotated images, and exportable reports, aiding compliance and warranty validation.

We offer end-to-end robotic inspection systems, including:

Everything is custom-built for your parts, process, and plant layout.

| Benefit | Impact |

|---|---|

| Full-surface inspection | No blind spots or missed defects |

| Micron-level accuracy | Reliable detection of the smallest imperfections |

| AI-driven software | Consistent, real-time quality decision-making |

| Robotic flexibility | Adaptable to various part shapes and sizes |

| Digital traceability | Improved compliance, warranty, and audit trails |

| Inline integration | Zero disruption to your production flow |

Intelgic robotic inspection system scans each headlamp from multiple angles:

All without human intervention.

Don't let defects slip through or slow down your production. Intelgic's Robotic Inspection System delivers:

Schedule a demo or discuss a custom solution.

©2025 Intelgic Inc. All Rights Reserved.