Automated Gas Cylinder Inspection System

Turnkey machine-vision AOI for internal wall, mouth threads, and valve seat inspection

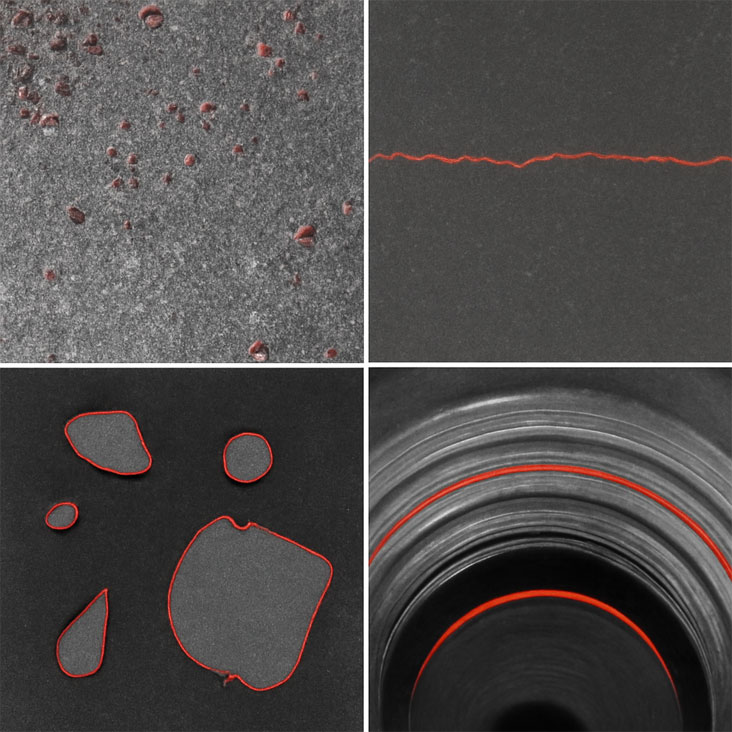

Intelgic’s Automated Gas Cylinder Inspection System uses borescopes, precision motion, and AI-powered vision to deliver 100% coverage of internal surfaces—finding corrosion, pitting, cracks, deposits, thread damage, and more. Generate a Digital Quality Certificate (DQC) for every PASS cylinder and drive toward Zero-Defect manufacturing.

Verify internal conditions before filling or re-certification.

Objective, recipe-driven decisions vs. subjective manual checks.

Image evidence, audit trails, and per-cylinder quality certificates.

Faster decisions, fewer reworks, and less line downtime.

Rust, corrosion, pitting, gouges, cracks, weld-seam defects, paint flakes/debris, residues, liquids.

Wear, burrs, cross-threading, chipping, contamination.

Damage, deposits, concentricity/geometry anomalies (visual).

Serial/OCR, label/barcode/QR verification for traceability.

Cylinder identified (serial/OCR/QR), clamped or positioned.

Optional purge/vent and air blow to remove loose debris.

Robotic actuator inserts the borescope/lighting; autofocus engages.

Cylinder/camera rotates while the probe moves axially; encoders ensure 100% coverage.

Live Vision AI detects/segments defects, sizes them, and applies your acceptance matrix.

PASS/FAIL issued; DQC and images archived to on-prem/cloud.

Note: Wall-thickness or structural integrity measurements are typically ultrasonic/pressure-test domains. Intelgic’s solution focuses on visual inspection and integrates easily with those stations.

Yes—our visual system detects surface anomalies, fiber/resin irregularities, contamination, and cracks visible to the camera. For structural integrity (delamination/wall thickness), we integrate with your specialized NDT processes.

We configure probe length, motion stroke, and fixtures for typical LPG/CNG/industrial and medical sizes. Share your SKUs and target cycle times; we’ll size the cell accordingly.

We offer explosion-resistant variants and engineered controls (purge/vent, interlocks) appropriate to your site’s zone classification and safety standards.

Through recipes: you choose thresholds for pit size, corrosion coverage, crack length, thread damage, contamination, etc. Recipes are version-controlled and role-gated.

Cylinder ID, images, defect metrics, decision (PASS/FAIL), recipe version, timestamp, line/station, and signatures—stored on-prem or cloud for audits and warranty validation.

Yes. We provide APIs/OPC-UA connectors and can push DQC, counts, and defect stats to your systems.

Let’s review your cylinder range, defects of interest, target takt time, and compliance needs. Intelgic will propose the optimal optics, motion, and AI stack—and deliver a pilot within a rapid timeline.

Contact us today©2025 Intelgic Inc. All Rights Reserved.