System Architecture

Precision-engineered components working in harmony to deliver unmatched inspection accuracy

Imaging Hardware

- High-resolution area-scan cameras with HDR

- Telecentric lenses for metrology

- Liquid lens for rapid autofocus

- Application-specific lighting geometry

Live Vision AI

- Recipe-based inspection per material

- Multi-view fusion and reflection-aware segmentation

- OCR/OCV for engravings and ink

- Real-time PASS/FAIL with reason codes

Integration Layer

- PLC/SCADA, MES/LMS via OPC-UA, Modbus/TCP

- Connectors to automated lensometers

- Data exchange with edgers/blockers

- REST APIs for BI tools integration

Optical Metrology Options

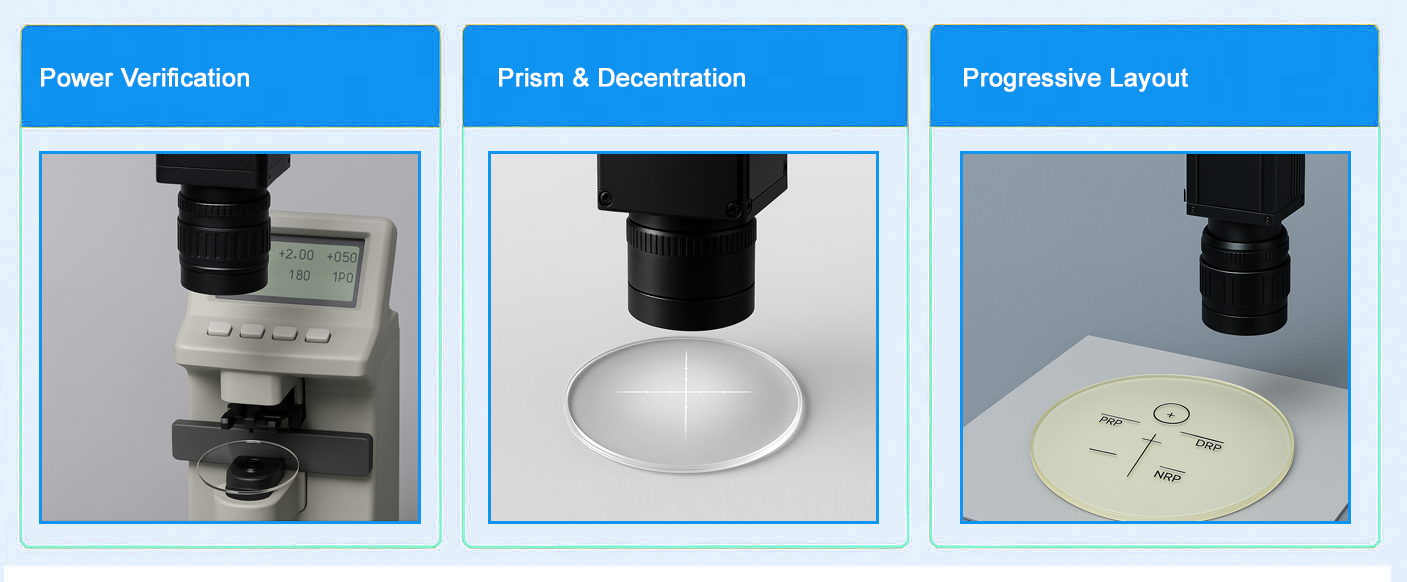

Power Verification

Integrate with electronic lensometer to log sphere, cylinder, axis, prism and reconcile with job ticket

Prism & Decentration

Measure optical center vs. engravings/fitting cross; compute base/apex and magnitude

Progressive Layout

Check engraving positions, corridor length, PRP/DRP/NRP distances to tolerance