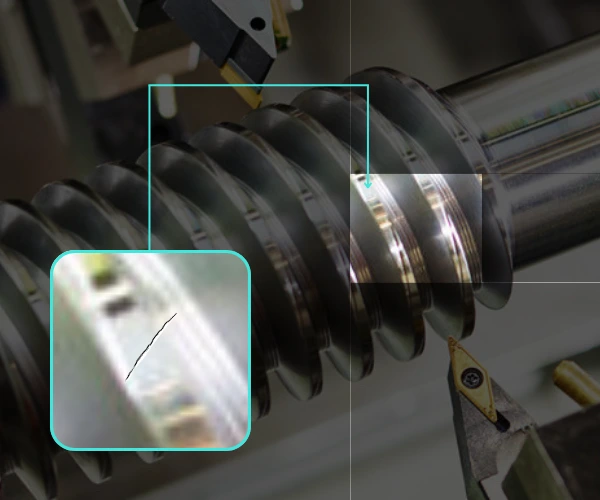

Micron-Level Defect Detection using AI powered AOI system

Detect defects ranging from 8 to 100 micrometers in size.

When it comes to manufacturing small, sensitive components, precision is not just a requirement—it is a necessity. Defects at the micron level can compromise product integrity, leading to costly rework, customer dissatisfaction, and even safety risks. Intelgic’s state-of-the-art micron-level defect detection solutions combine advanced imaging technologies, AI-driven analysis, and automation to deliver unparalleled accuracy and efficiency.

Micron-level defects are often invisible to the naked eye but can have significant impacts on the performance and reliability of precision components. Industries like medical devices, automotive, aerospace, and electronics demand flawless parts, where even the smallest imperfection can lead to:

Intelgic’s solutions address these challenges head-on, ensuring that every part meets the highest quality standards.

Intelgic’s micron-level defect detection system leverages cutting-edge hardware and AI to detect even the smallest anomalies with speed and accuracy.

Detects defects as small as a few microns, ensuring zero-compromise on quality.

AI processes images instantaneously, providing immediate feedback and reducing downtime.

Tailored to meet specific industry requirements, from component size to inspection speed.

Easily integrates into existing production lines, enhancing your workflow without disruption.

Handles high-volume production with ease, improving throughput while maintaining accuracy.

Minimizes rework and rejects, reducing operational costs and increasing profitability.

Intelgic's micron-level defect detection systems are trusted by leading manufacturers across industries

Our team has years of experience designing and implementing vision systems for complex applications.

Intelgic's Live Vision AI software is purpose-built for high-precision defect detection.

We work closely with clients to deliver tailored systems that meet their unique challenges.

From hardware selection to installation and ongoing support, Intelgic provides a complete solution.

Achieve flawless manufacturing with Intelgic's micron-level defect detection solutions. Whether you need to inspect thousands of parts per hour or detect the tiniest imperfections, we have the technology and expertise to make it happen.

Contact us today©2025 Intelgic Inc. All Rights Reserved.