CIS Cameras: High-Resolution Scanning for Flawless Surface Inspection and microscopic defect detection

Book a call

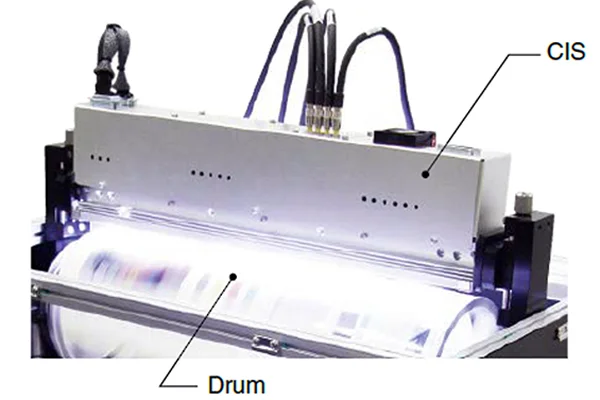

Contact Image Sensor (CIS) cameras are specialized imaging devices designed for applications requiring high-resolution scanning and precise inspection of flat or continuous surfaces. Unlike traditional cameras that use lenses to capture images from a distance, CIS cameras employ a linear array of sensors positioned in close proximity to the object being scanned. This unique design enables CIS cameras to deliver highly detailed, distortion-free images, making them ideal for detecting microscopic defects on a wide range of materials, including paper, textiles, metal sheets, and more.

CIS cameras are particularly well-suited for industries where the inspection of large, flat, or continuous surfaces is critical. They excel in applications requiring high accuracy and consistency, such as:

CIS cameras offer several distinct advantages that make them the preferred choice for certain inspection tasks:

While CIS cameras offer numerous benefits, there are some limitations to consider:

CIS cameras are a powerful tool for industries that require high-resolution, distortion-free imaging of flat or continuous surfaces. Whether you’re inspecting printed materials, textiles, metal sheets, or electronic displays, CIS cameras provide the accuracy and detail needed to ensure product quality. While they are best suited for specific applications, their ability to deliver precise, consistent results makes them an invaluable asset in modern manufacturing and quality control processes.

Contact Us©2025 Intelgic Inc. All Rights Reserved.