Assembly Monitoring and Verification with Warranty Validation through Digital Quality Certificate (DQC)

Ensure Quality, Traceability, and Customer Confidence with Intelgic’s AI-Powered Vision System

Book a call

Even a small assembly error can lead to product failures, customer dissatisfaction, and costly warranty claims.

Without proper monitoring, manufacturers lack documentation to verify correct assembly or validate warranty claims.

Traditional quality checks are manual, inconsistent and often rely on sampling, allowing defective products to slip through undetected.

Difficulty tracking issues across shifts, batches, or suppliers leads to prolonged problem resolution.

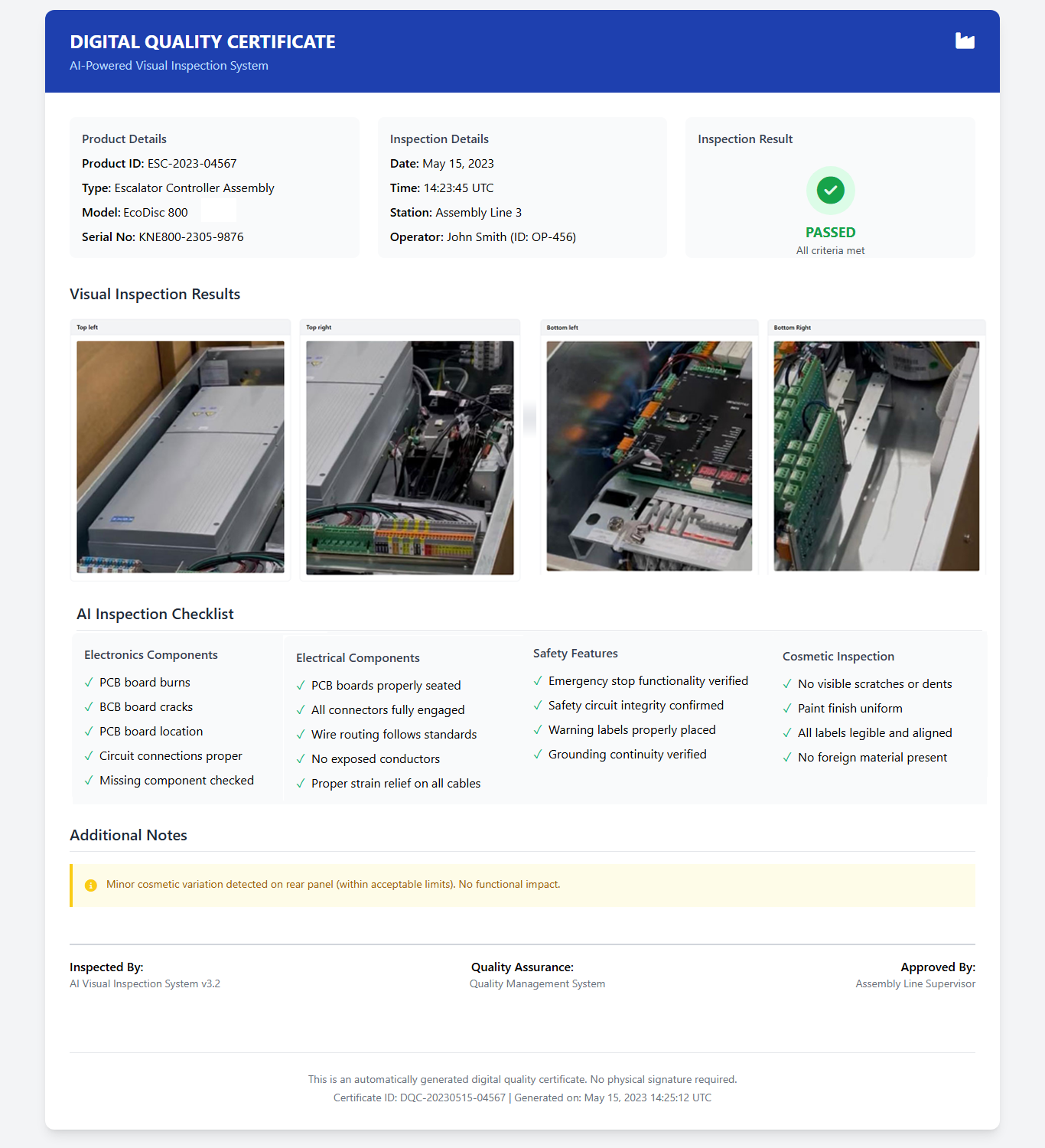

Intelgic’s Assembly Monitoring System ensures no defective product is shipped. Generate a Digital Quality Certificate (DQC) for every defect-free product and deliver with confidence.

Our AI-powered system verifies every component in an assembly is present, correctly oriented, properly fastened, and installed in the right sequence according to SOPs.

Either get real time alerts for incorrect assembly and let the operators fix it before shipment Or Get a Digital Quality Certificate (DQC) for each correctly assembled product.

Instant alerts for missing fasteners, misaligned parts, or incorrect wiring before final installation.

Get immutable proof of quality for every unit shipped, ready for audits and warranty validation.

Leverage error trend analytics to reduce recurring defects and warranty claim rates by 80-90%.

Our solutions work across diverse industries to ensure assembly accuracy and quality.

Verification of electrical components, wiring harness connections, safety components, and mechanical assemblies.

Component presence, orientation, and solder joint inspection for PCBs and electronic assemblies.

Inspection of machined, molded, or fabricated parts for dimensional accuracy and assembly completeness.

Assembly verification for complex modules like dashboards, headlamps, and wiring harnesses.

Multi-stage verification of subassemblies, control panels, and safety systems.

Inspection of HVAC systems, washing machines, and kitchen appliances for assembly accuracy.

End-to-end assembly monitoring and warranty validation workflow

Scan barcode/QR/RFID to load the correct SOP recipe and station checks for that variant.

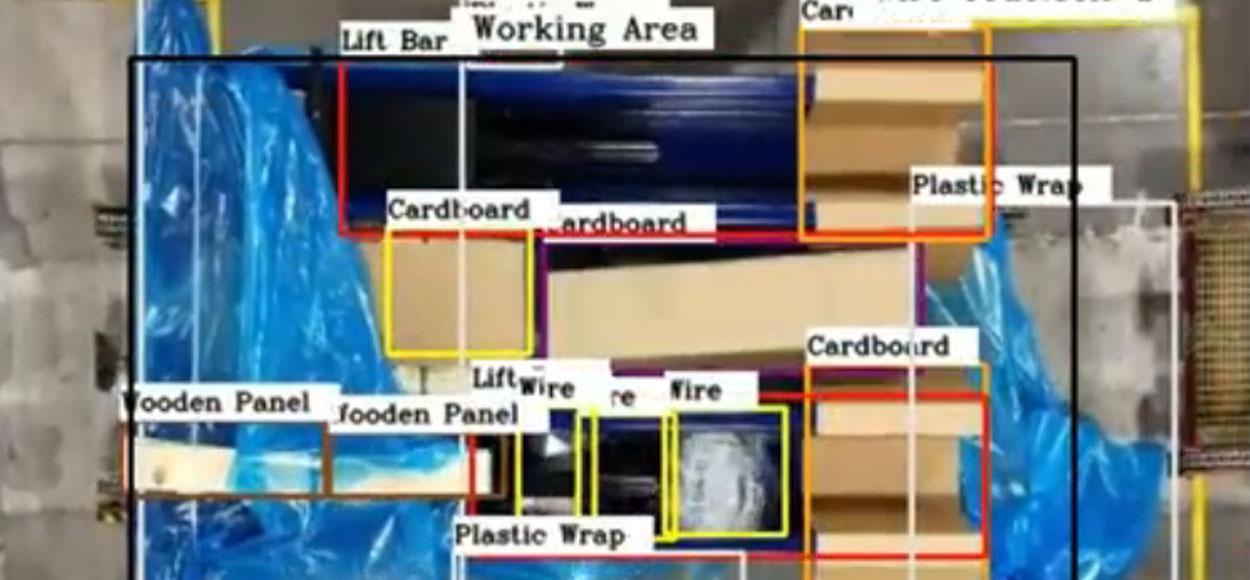

Cameras capture at each critical step. AI verifies component presence, orientation, fasteners, and more.

Pass → advance; Fail → stop/andon; Ambiguous → escalate to assisted review.

On unit completion, generate a Digital Quality Certificate with images, results, and timestamps.

Every product ships with immutable proof of quality, enabling fast and fair warranty claim resolution.

Customer submits warranty claim with product serial/RMA number.

System auto-fetches DQC with images & pass history at each assembly step.

Factory miss: Identify station/recipe drift; launch CAPA. No nonconformance: Provide DQC to customer.

Post outcome & lessons to MES/QMS; update analytics for continuous improvement.

Measurable impact on your key performance indicators

Prevent defects during assembly rather than after packaging.

Leverage error trend analytics to identify and eliminate root causes.

Real-time defect alerts and error history shorten Mean Time to Repair.

Digital proof of quality resolves claims faster and reduces goodwill costs.

DQCs ensure compliance with ISO, IATF, and industry standards.

Transparent quality documentation builds confidence in your brand.

End-to-end solution built on industrial-grade components

Answers to common questions about our assembly monitoring solution

©2025 Intelgic Inc. All Rights Reserved.