AI-Powered PCB Board Inspection for Component Verification and Warranty Validation

Book a call

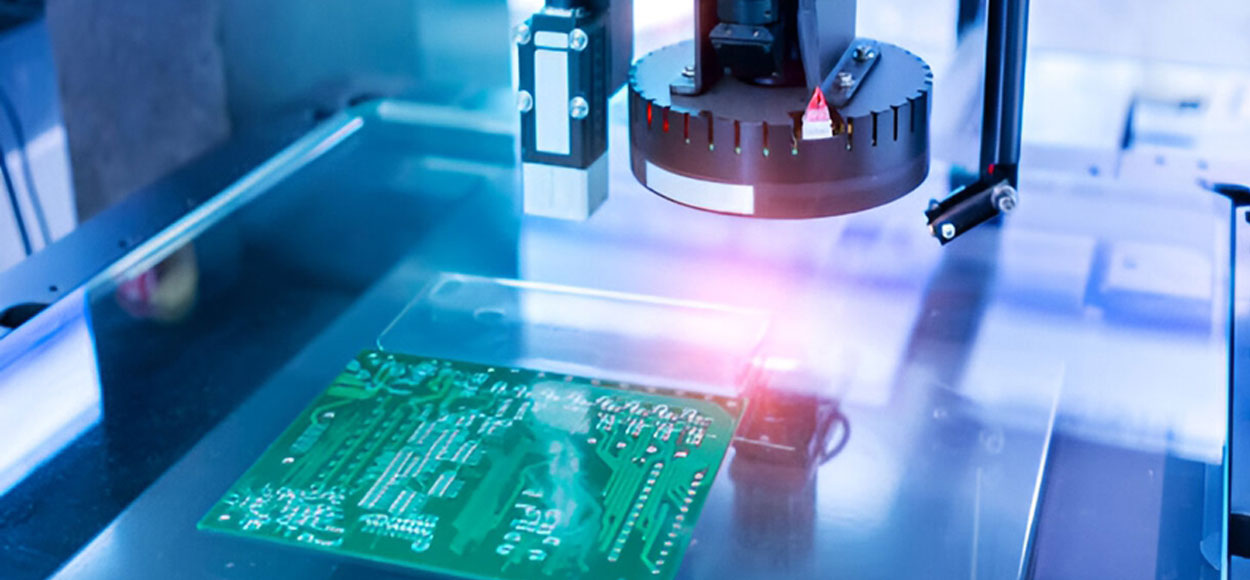

PCB boards are the foundation of modern electronic devices, and each board contains hundreds—sometimes thousands—of tiny, intricate components. During the assembly process, particularly with Through-Hole Assembly (THA), issues such as missing components, placement errors, or soldering defects can easily occur. These issues often go unnoticed during manual checks, leading to product failures, warranty claims, and costly rework.

Intelgic provides a comprehensive, AI-powered PCB board inspection system that detects, identifies, and counts every single component on a PCB, ensuring that assembly errors are caught early and quality is assured at every stage.

Our AI-powered system detects, identifies, and counts every component on your PCBs with unmatched precision.

Scans each PCB and verifies all components against the original design, flagging any missing parts with precise location and visual evidence.

Performs pixel-level analysis to identify and count every component, matching against the Bill of Materials (BoM) and ensuring correct placement.

Detects critical errors including misaligned components, soldering issues, wrong components, incomplete insertions, and improper spacing.

Reads alphanumeric text, codes, or IDs on micro-components to verify correct types, polarity, or batch tracking information.

Generates comprehensive reports with high-res images, defect markers, and a Digital Quality Certificate for traceability and warranty validation.

Seamlessly integrates with existing SMT/THA lines and MES systems, with API support for ERP and QA system connectivity.

Built with cutting-edge automation and vision systems for unparalleled inspection accuracy.

High-resolution industrial cameras capable of capturing fine details at micro level.

Custom lighting configurations (dome, ring, coaxial) for uniform and glare-free imaging.

Automated XYZ motion rails to move cameras with precision for large PCBs.

Advanced algorithms trained specifically for PCB component detection and classification.

Our PCB inspection platform delivers value across multiple industries.

Ensure quality in smartphones, tablets, wearables, and home appliances.

Critical inspection for ECUs, battery management systems, and vehicle control units.

High-reliability inspection for diagnostic equipment and implantable devices.

Quality assurance for PLC boards and industrial automation systems.

Precision inspection for server boards and networking equipment.

Mission-critical inspection for avionics and military electronics.

Transform your quality control process with our AI-powered inspection system.

Detects missing, misplaced, and incorrect components with 99%+ accuracy.

Counts and verifies every component against BoM/design files automatically.

Reduces warranty issues with traceable digital certificates for every PCB.

Ensures compliance with IPC and OEM quality standards consistently.

Connects with existing SMT/THA lines and MES systems effortlessly.

Reduces rework costs and improves first-pass yield significantly.

Each inspection is stored with time-stamped data, creating an immutable quality record for warranty validation and batch traceability.

Sample inspection certificate generated by our system.

We deliver complete turnkey PCB inspection solutions tailored to your specific needs.

Camera and lighting setup optimized for your specific board layouts and components.

PLC-controlled motion systems for micron-level accuracy in component imaging.

On-premise or cloud deployment options to match your infrastructure needs.

Contact Intelgic today to learn how our AI-powered PCB inspection system can enhance your production accuracy, reduce defects, and streamline warranty validation.

Get Started Now©2025 Intelgic Inc. All Rights Reserved.