Clear Automotive Parts Inspection Using Machine Vision and AI

Book a call

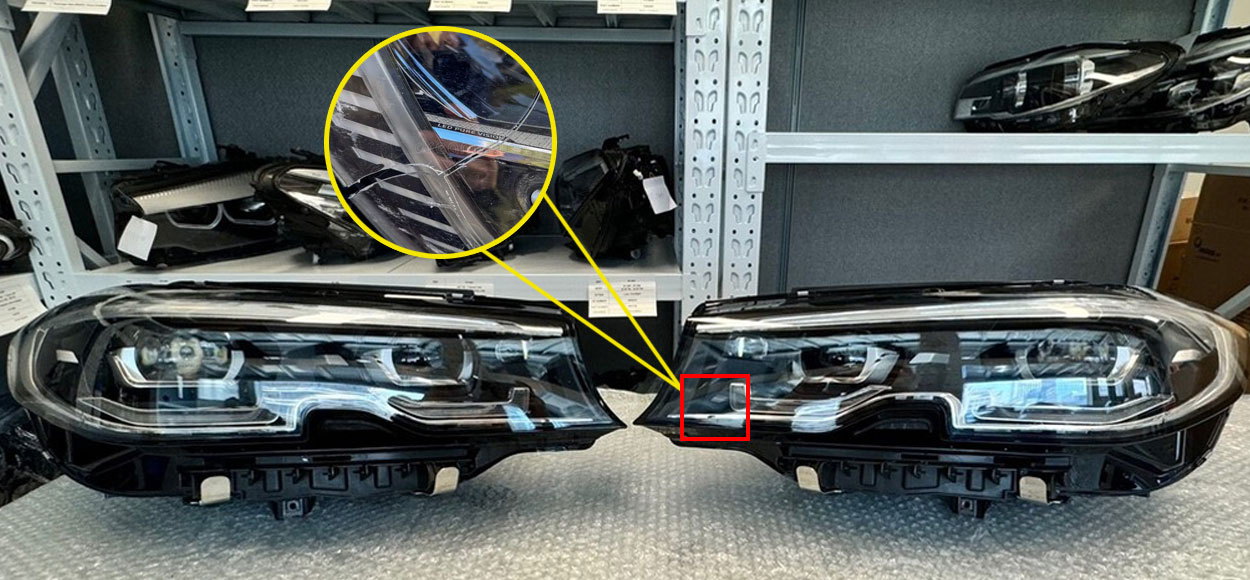

Clear and transparent automotive components—such as indicator covers, instrument clusters, light guides, sensors, lenses, and glass panels—play a critical role in both vehicle aesthetics and functionality. However, due to their transparent nature, these parts present unique inspection challenges. Scratches, cracks, pinholes, and contamination—even when extremely small—can compromise quality, performance, and customer satisfaction.

Manual inspection methods fall short when it comes to identifying such defects consistently. Operators often miss subtle surface imperfections due to optical illusions, reflections, and invisible micro-defects. To address these challenges, Intelgic offers a fully automated, machine vision-based inspection system, designed specifically for transparent automotive parts.

Transparent materials like clear plastics and glass do not reflect light in a consistent way.

Defects often blend into the background, making it difficult to detect with the naked eye or under general-purpose lighting.

Small defects such as:

These may only be visible from certain angles or under specialized lighting.

Standard lighting can cause:

These distort the image or mask the defect entirely.

Clear parts may be:

This requires dynamic camera positioning and custom lighting to inspect all surfaces accurately.

Intelgic provides an end-to-end automation platform for inspecting transparent automotive parts, including:

Transparent part inspection requires a highly engineered lighting setup:

Lighting is dynamically adjusted per part type and inspection requirement, ensuring contrast-rich and defect-visible images.

For parts with 3D geometries or hidden surfaces, Intelgic uses:

The motion system is fully synchronized with the camera triggers and inspection software.

Intelgic’s Live Vision AI software analyzes each image in real time:

Part arrives at the inspection station via conveyor or robotic handler.

Lighting and camera positions are adjusted automatically based on part type.

Multiple images are captured from different angles (top, side, diagonal, backlight).

Defective parts are flagged or diverted, while all inspection data is stored for traceability.

Scratches, bubbles, mold marks

Contamination, fine cracks

Internal air pockets, surface hazing

Color defects, pinholes

Chips, edge cracks, coating smears

Optical distortions, surface imperfections

| Benefit | Description |

|---|---|

| High Detection Accuracy | Detects even micron-level surface and internal defects |

| Fully Automated | Reduces reliance on manual operators and inconsistency |

| Custom Lighting | Tailored for transparency, glare reduction, and contrast |

| AI-Driven Analysis | Learns and adapts to different defect types and part geometries |

| Real-Time Feedback | Enables instant response and part rejection |

| Data Logging & Traceability | Images, results, and analytics are stored for audits and reports |

Transparent automotive components require a precise and intelligent inspection approach that goes far beyond traditional vision systems. Intelgic's comprehensive solution—combining specialized lighting, advanced machine vision, motion systems, and AI-driven analytics—offers manufacturers the ability to reliably detect even the smallest defects in clear plastic and glass parts.

By automating this inspection process, Intelgic helps automotive suppliers reduce rework, eliminate quality escapes, and ensure customer satisfaction—all while improving production efficiency and compliance.

©2025 Intelgic Inc. All Rights Reserved.