Machine Vision System for Automated Defect Detection

Intelgic's Machine Vision solution is specifically designed to automate visual inspection processes in the manufacturing and supply chain industry.

High-resolution cameras capture every detail with precision, ensuring no defect goes unnoticed.

Our cutting-edge AI algorithms identify defects that are often missed by the human eye.

Real-time inspection at production line speeds without compromising accuracy.

Our machine vision system is tailored to meet the rigorous demands of various industries.

Inspect various components to ensure the highest quality standards.

Ensuring the integrity and finish of metal surfaces.

Critical for ensuring product reliability and performance.

Vital to maintain product safety and efficacy.

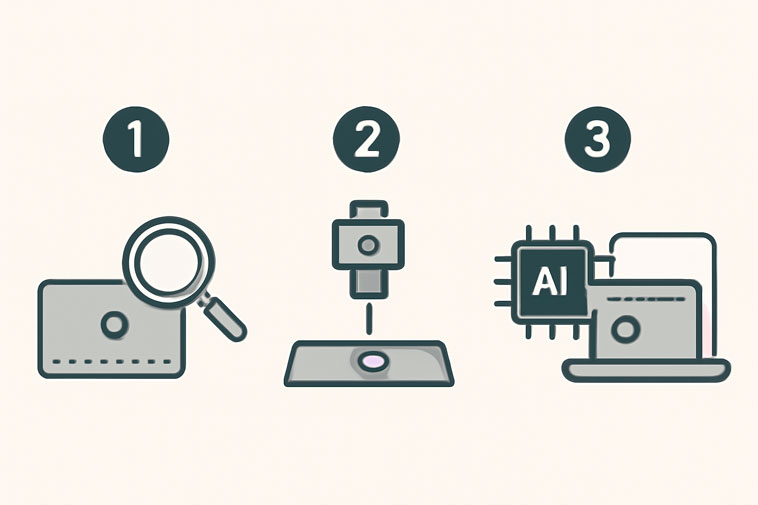

Our comprehensive process ensures your defect detection system is perfectly tailored to your needs.

Assess defect size, product dimensions, line speed, and other critical factors.

Choose the appropriate camera and lens based on the identified factors.

Use the collected data to train the AI for accurate defect detection.

©2025 Intelgic Inc. All Rights Reserved.