Advanced Defect Detection in Coating and Printing

As the plastic industry evolves, the diversity in product color, transparency, and size presents unique challenges in quality control. Our cutting-edge system is specifically tailored to address these complexities, ensuring meticulous defect detection and precise dimensional measurement across a vast range of plastic products.

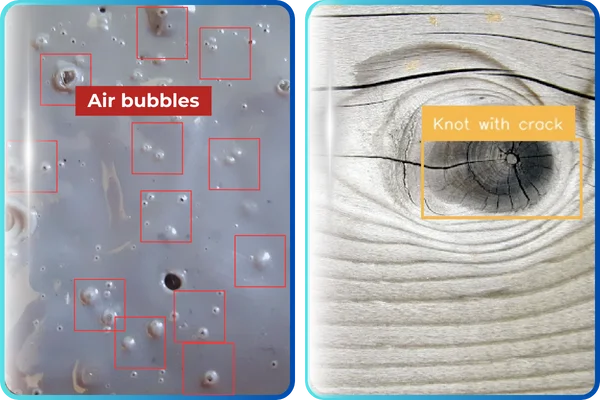

Plastic products, varying from opaque to translucent and transparent, are integral in countless applications. Detecting defects, especially in white or clear plastics, poses significant challenges due to their nature. Minor imperfections like hairline scratches, which are often invisible to the naked eye, can drastically affect the quality and functionality of the final product. Furthermore, achieving the correct lighting conditions to highlight these defects is another hurdle traditionally faced in the industry.