Metal Sheet Inspection in Cut-to-Length Line

Real-Time Defect Detection and Dimensional Measurement in Running Lines

Book a call

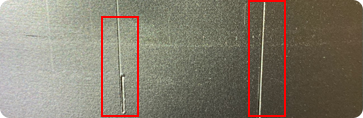

In Cut-to-Length (CTL) operations, where metal coils are flattened and cut into sheets, maintaining surface quality and dimensional accuracy is essential. Defects and miscuts can compromise downstream manufacturing and cause significant material loss.

Intelgic’s AI-driven Machine Vision Solution offers real-time inspection of metal sheets in motion, ensuring each plate is defect-free and meets the exact length and width specifications—all without slowing down the production line.

Detect surface anomalies in real time across both top and bottom surfaces.

Precise inline measurement of each sheet with real-time validation.

Comprehensive plate tracking with quality data for every sheet.

System Architecture

Intelgic deploys a line scan-based imaging system synchronized with the CTL line. Key components include:

High-resolution cameras placed above and below the sheet

Custom linear lighting optimized for metal surface contrast

Accurate sheet measurement and synchronization

Advanced algorithms for defect detection and measurement

Powerful processing for real-time inspection

PLC connectivity and data exchange with MES/ERP

We deliver a complete inspection system engineered for CTL operations:

Line scan cameras, industrial lenses, and custom lighting setup (top and bottom)

Robust mechanical design for industrial environments

Advanced inspection and measurement algorithms

Reporting interface with defect map visualization

On-site setup, system calibration, and operator training

Ongoing technical support and system optimization

Per-plate report including:

Batch-wise summary and coil-level inspection data

Exportable reports for QA, traceability, and compliance audits

Mills and processing plants producing flat-rolled metal products

Tier 1 and Tier 2 suppliers of automotive metal components

Manufacturers of appliances, roofing and building products

Service centers and fabricators processing metal sheets

Intelgic’s real-time inspection system ensures every plate meets quality and dimensional standards—before it reaches your customer.

Schedule a demo or contact us to learn how Intelgic can automate your CTL inspection process.

©2025 Intelgic Inc. All Rights Reserved.