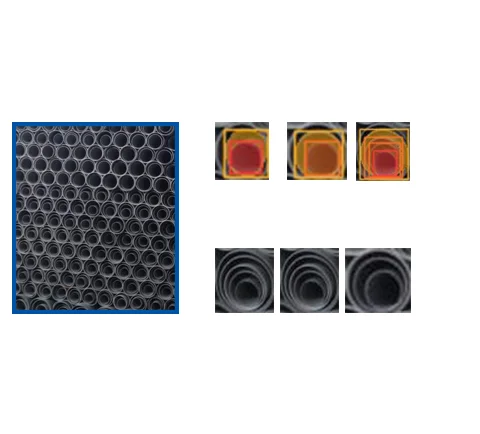

Pipe Counting using Vision AI and cameras

- Pipe counting system for pipe manufacturers

- Nested pipe counting

- Telescopic pipe counting

- Count pipes in warehouses and on loaded trucks during shipment.

Our system automates the pipe counting process using advanced vision AI technology and sophisticated image processing algorithms. The AI-driven pipe counting system operates with a camera that captures images of the pipes. These images are then processed by AI algorithms, which can run either on a cloud server or an on-premises server, to provide accurate pipe counts. This ensures efficient and precise inventory management in real-time.

Manufacturers optimize transportation and storage by employing pipe nesting, where smaller diameter pipes are inserted into larger ones. This technique enhances space efficiency, reduces transportation costs, and ensures organized storage, facilitating easier handling and inventory management in warehouses and during shipment.

However, counting nested pipes presents a tedious and error-prone challenge for workers during shipment and inventory audits. Our advanced AI algorithm addresses this issue by using a camera with proper lighting conditions to capture images or videos of the pipes. The AI technology accurately identifies and counts nested pipes, providing highly precise inventory data and streamlining the counting process

Manufacturers should transform the manual counting process to an AI-driven system due to the following benefits:

| Criteria | Manual Counting | AI-driven Automated Counting |

|---|---|---|

| Accuracy | Prone to human errors | Highly accurate |

| Efficiency | Low | High |

| Time Consumption | High | Low |

| Error Rate | High | Minimal |

| Cost Effectiveness | Costly due to labor | Cost-effective in the long run |

| Scalability | Limited | Easily scalable |

| Labor Intensity | High | Low |

| Real-time Monitoring | Not possible | Possible |

| Data Analytics | None | Advanced insights and analytics |

Improved Accuracy: AI significantly reduces human errors.

Enhanced Efficiency: Automation streamlines the counting process.

Time Savings: systems complete tasks much faster.

Reduced Error Rate: Minimal errors compared to manual counting.

Cost Effectiveness: Lower long-term costs despite initial investment.

Scalability: scalable to accommodate larger operations.

Reduced Labor Intensity: Less manual labor required.

Real-time Monitoring: Enables continuous, real-time monitoring.

Advanced Data Analytics: Provides detailed insights and analytics.

Pipes are typically transported via trucks, making it crucial to keep track of the number of pipes loaded onto each vehicle during shipment. By installing a camera in the shipping area, images of each loaded truck can be captured, enabling instant pipe counting. This system ensures accurate inventory management, reduces manual counting errors, and streamlines the logistics process, providing real-time data on the number of pipes being shipped.

A camera captures images or videos of the bundles of pipes. High-resolution cameras are recommended to ensure that individual pipes within the bundles can be clearly distinguished.

The captured images are preprocessed to enhance clarity and contrast. This step may include adjusting brightness, filtering noise, and applying edge detection techniques to highlight the outlines of the pipes.

The AI algorithm counts the number of distinct pipes. Machine learning models, trained on a variety of pipe images and bundle configurations, improve the accuracy of this step.

Location Selection: Choose a strategic location in the shipping area where the camera has a clear and unobstructed view of the pipes. The camera should be focussed to capture the entire counting region.

Mounting: Securely mount the camera at an appropriate height to ensure it captures high-resolution images of the pipes. The mounting equipment should be sturdy to prevent any movement or vibration that could affect image quality.

Lighting Conditions: Ensure the area is well-lit to avoid shadows and improve image clarity. Consider installing additional lighting if necessary to maintain consistent lighting conditions, especially in areas prone to low light or during night operations.

Camera Specifications: Select an machine vision camera with high resolution and good low-light performance to capture clear images. Features such as zoom, autofocus, and wide-angle lenses can enhance image capture quality.

Connectivity: Connect the camera to the AI system through a reliable network. This could be via Ethernet, or other suitable methods. Ensure the network is robust to handle real-time data transmission without interruptions.

Calibration and Testing: Calibrate the camera to ensure it is correctly aligned and focused. Conduct test runs to verify that the camera captures accurate images and that the AI system can correctly count the pipes.

Proper lighting is crucial for the AI pipe counting system to function accurately. Here are the key aspects to consider for optimal lighting conditions:

Uniform Lighting: Ensure that the entire area where the pipes are being counted is evenly lit. Avoid areas with significant light and shadow contrasts, as these can cause inaccuracies in image processing.

Brightness: Maintain sufficient brightness to ensure that the camera can capture clear and detailed images.

Consistent Lighting: Maintain consistent lighting conditions throughout the day. If the area is subject to natural light variations, consider using artificial lighting to supplement and stabilize the lighting environment.

Placement of Lights: Strategically place lights to illuminate the pipes from multiple angles, ensuring that no part of the bundles is in shadow.

Control Reflections: If pipes are shiny or reflective, ensure that lighting angles and types are chosen to minimize reflection issues. Polarized lighting or anti-glare coatings on the pipes may be considered if reflections are problematic.

Stability: Ensure that the lighting fixtures are stable and do not flicker, as inconsistent lighting can disrupt the AI's image processing capabilities.

Yes, the AI system can detect pipe defects. Here's how it works:

We can train our AI System for Pipe Defect Detection specifically for you. We need images of pipe defects that you are encountering within your manufacturing facility. We will train the AI with the images and connect with cameras installed at your manufacturing lines.

©2025 Intelgic Inc. All Rights Reserved.