Control Panel Box Inspection Using AI and Machine Vision

Book a call

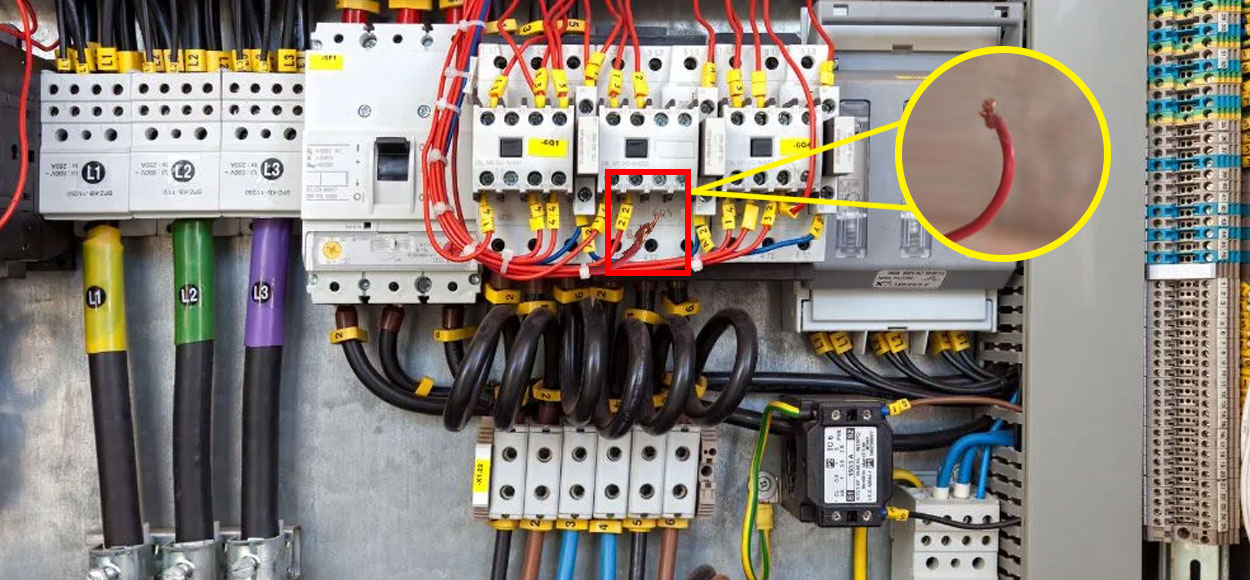

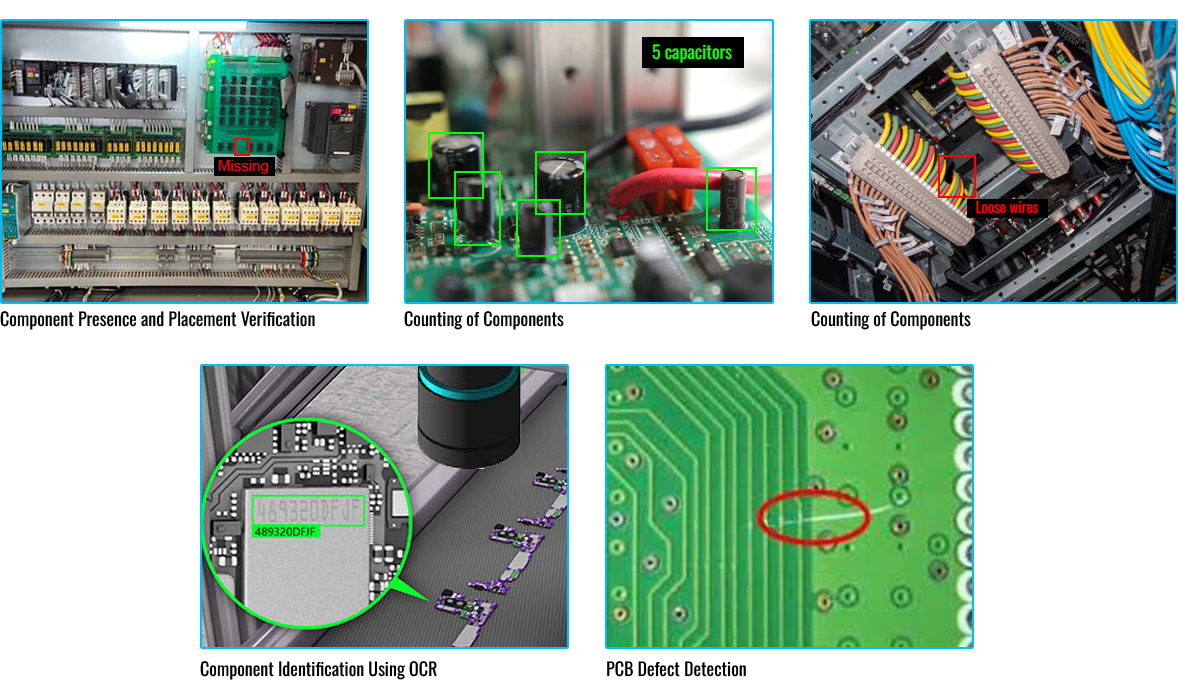

Modern industrial systems rely heavily on control panel boxes to house and manage critical electronic components. Ensuring the accuracy, completeness, and quality of these panels is vital to operational safety, efficiency, and compliance. Intelgic provides an advanced AI-powered control panel box inspection solution that leverages machine vision cameras, robotic imaging systems, and intelligent image processing software to inspect each panel down to the finest detail.

Intelgic’s AI-driven inspection system is designed to ensure that every control panel is complete, correctly assembled, and defect-free—regardless of size or complexity.

To accommodate control panels of various sizes, shapes, and layouts, Intelgic integrates a range of hardware and imaging technologies:

At the heart of the solution is Live Vision AI—Intelgic’s proprietary software platform designed for real-time image processing and defect detection.

Intelgic’s control panel box inspection solution is industry-agnostic, designed to meet the needs of multiple sectors where control panel integrity is critical:

Intelgic’s AI-powered control panel box inspection system transforms how manufacturers validate the assembly and quality of control panels. With precision imaging, advanced AI, and flexible mechanical design, the system ensures that every component is present, correctly placed, and defect-free. This solution not only enhances product quality but also reduces rework, improves traceability, and safeguards industrial safety.

If you’re looking for an inspection solution that adapts to your panel designs and scales across industries, Intelgic’s Live Vision AI system is the complete, customizable platform you need.

©2025 Intelgic Inc. All Rights Reserved.