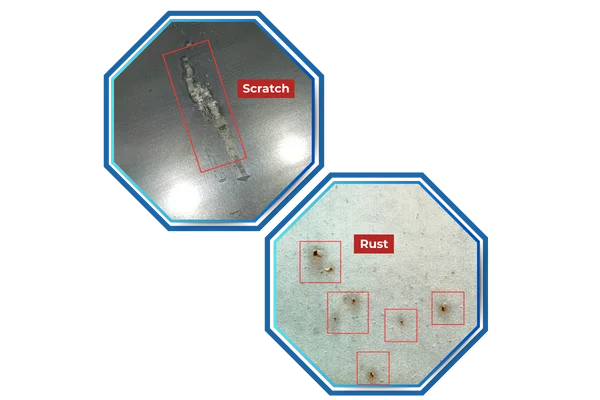

State of Art AI for defect detection and dimension measurement

In the metal, steel, and machinery industries, even the smallest imperfections can lead to significant consequences, including structural failures or costly recalls. Intelgic’s Machine Vision System is designed to identify a comprehensive range of defects with unparalleled accuracy. Our system leverages the power of Artificial Intelligence to achieve unmatched defect detection capabilities.