Machine Vision Illumination for Defect Detection and Inspection

Book a call

Lighting plays a critical role in the performance of a machine vision system, especially for tasks like defect detection, measurement, inspection, counting, and tracking. Proper lighting enhances image quality, ensuring accurate processing and reliable results. The right combination of lighting techniques and angles can make the difference between success and failure in defect detection.

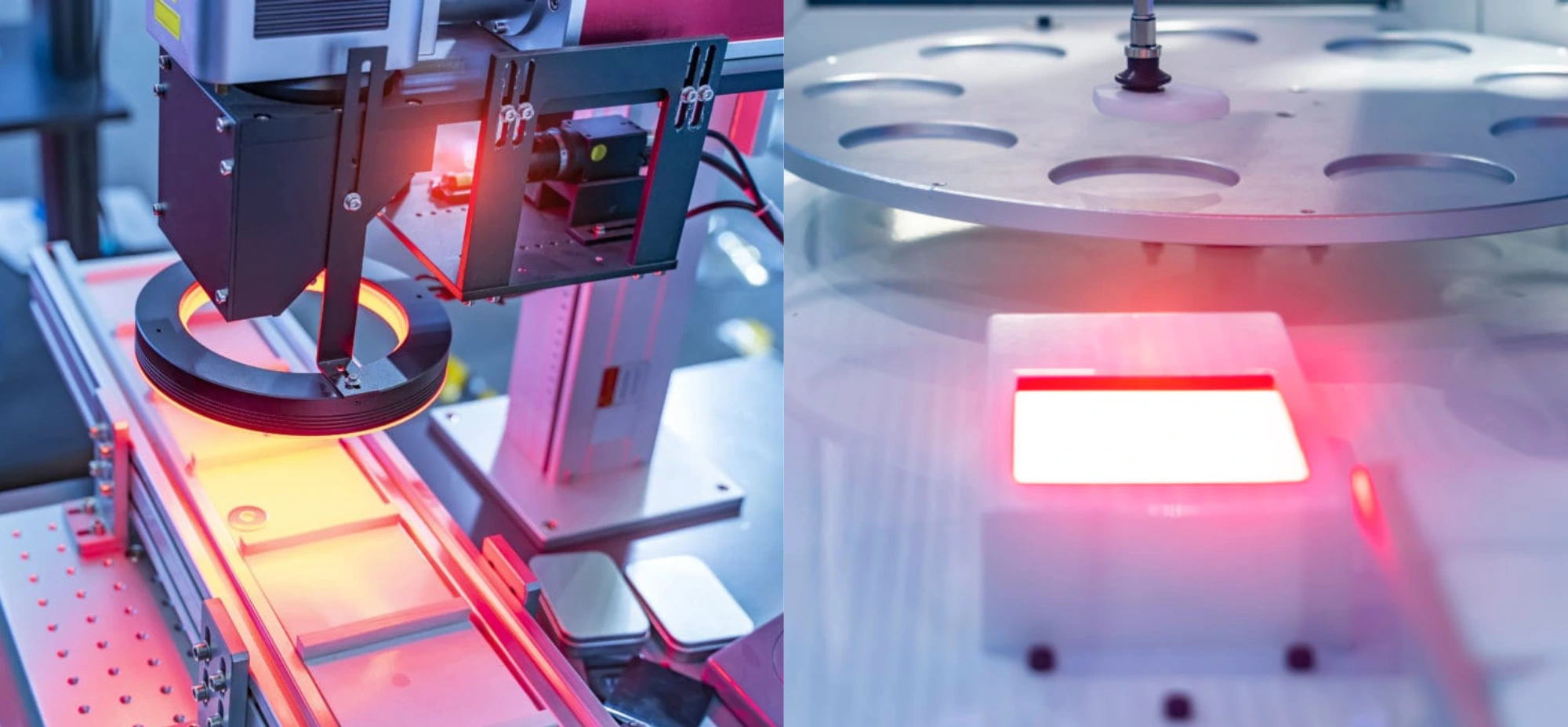

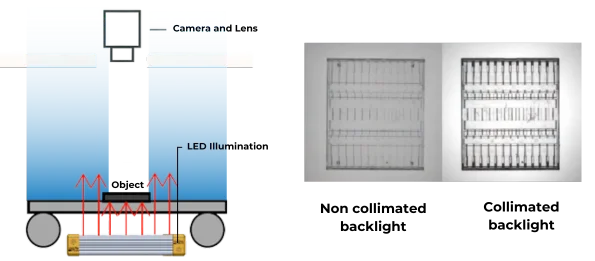

Backlighting illuminates the object from behind, creating a sharp contrast between the object and the background. It is ideal for edge detection, measurement, and silhouette-based inspections.

Common applications: Gauging, profile inspection, and detection of transparent materials.

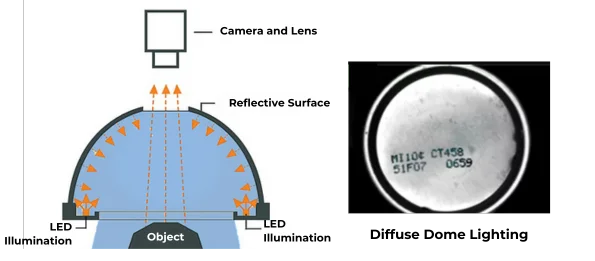

This lighting provides even, shadow-free illumination by reflecting light from a dome-shaped surface. It is perfect for highlighting subtle surface features without causing glare.

Common applications: Inspection of shiny or reflective surfaces like metal, glass, or plastics.

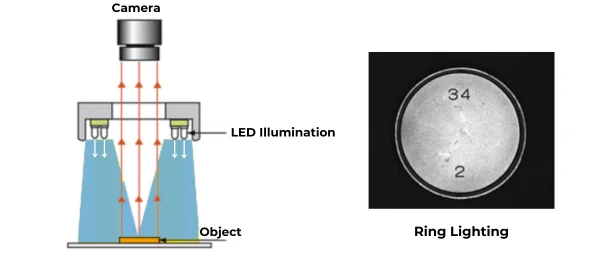

Positioned around the camera lens, ring lights provide uniform, directional light toward the object. This method is useful for general-purpose lighting and can help to reduce shadows.

Common applications: Inspection, tracking, and counting of small objects.

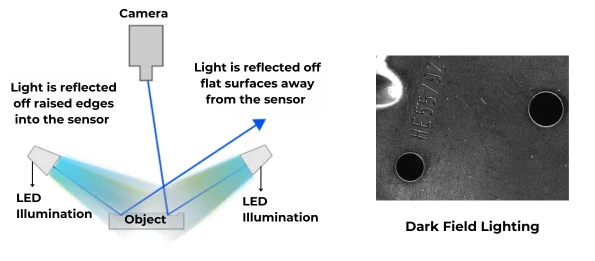

This technique involves placing the light at a low angle, which highlights surface textures, scratches, or defects by casting shadows on the surface imperfections.

Common applications: Surface defect detection in materials like glass, plastic, and polished metals.

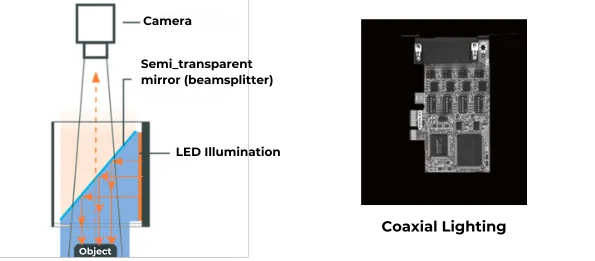

Coaxial lighting is a type of illumination that emits light vertically onto a target from the same axis as the camera and lens. It's also known as brightfield illumination or diffuse on-axis lighting

Common applications: Inspection of flat, reflective surfaces such as wafers and LCD panels.

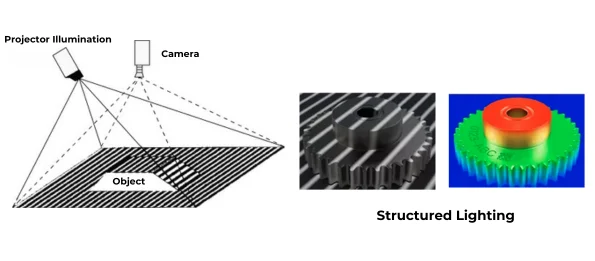

Projecting patterns like grids or stripes onto an object, structured lighting can enhance 3D surface inspection and measurement.

Common applications: Height measurement, 3D inspection, and volume analysis.

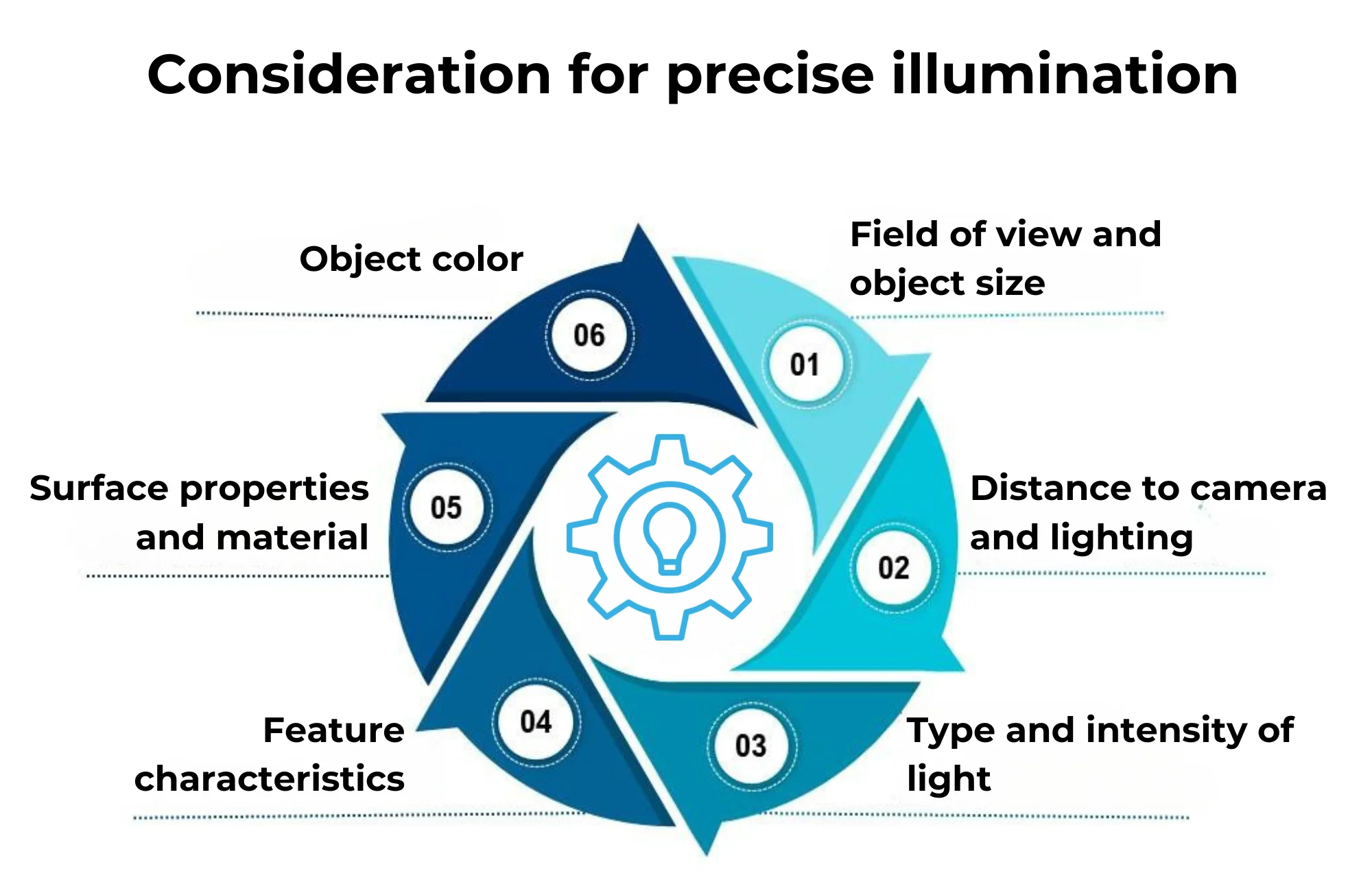

Selecting the ideal lighting for a machine vision system requires careful consideration of various factors, each influenced by the object being inspected, the features that need to be detected, and the layout of the system. To ensure precise illumination, ask yourself the following:

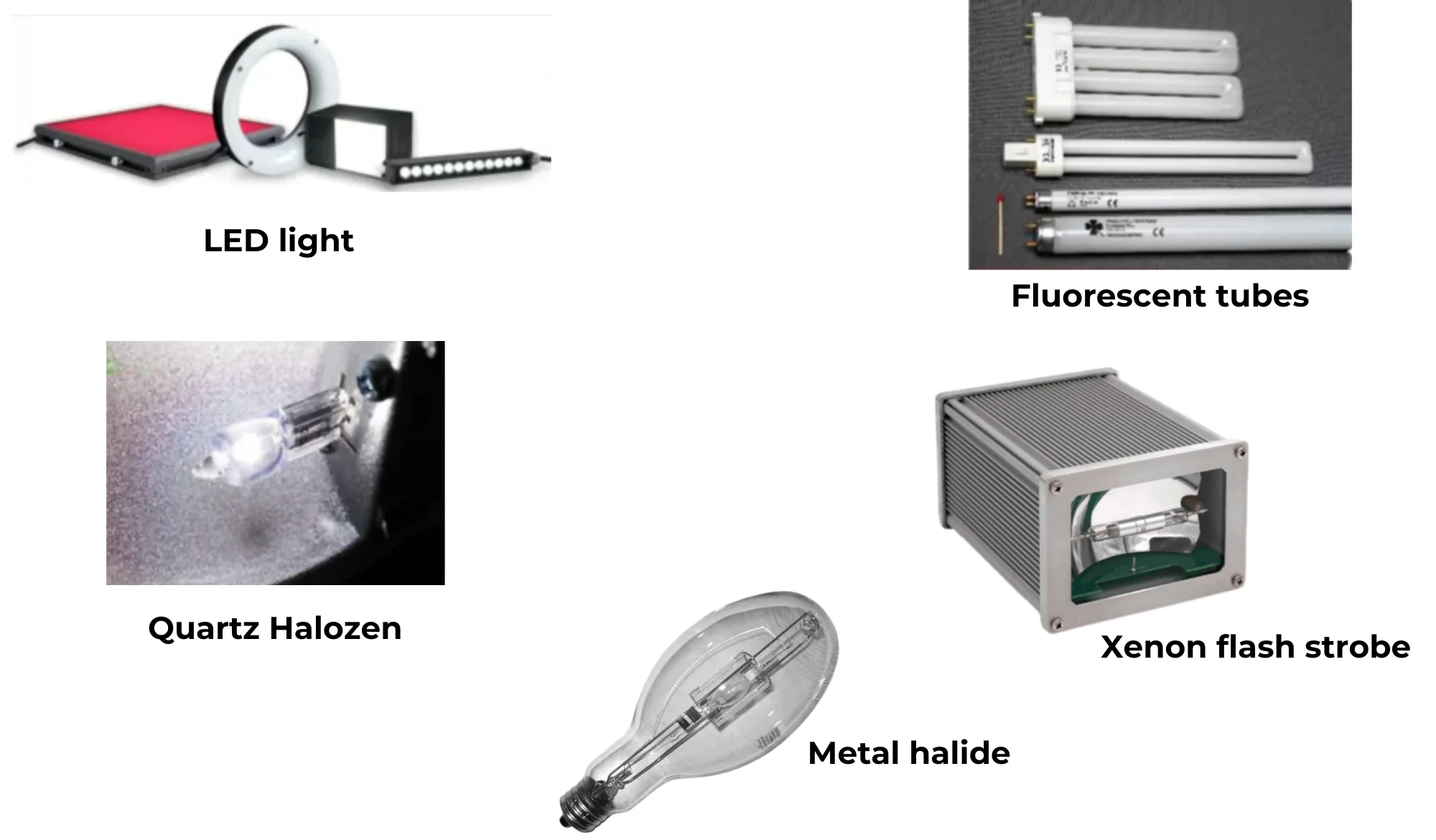

In machine vision, several types of lighting sources are commonly used:

Each lighting type serves different purposes depending on the scale of the inspection and the specific lighting requirements.

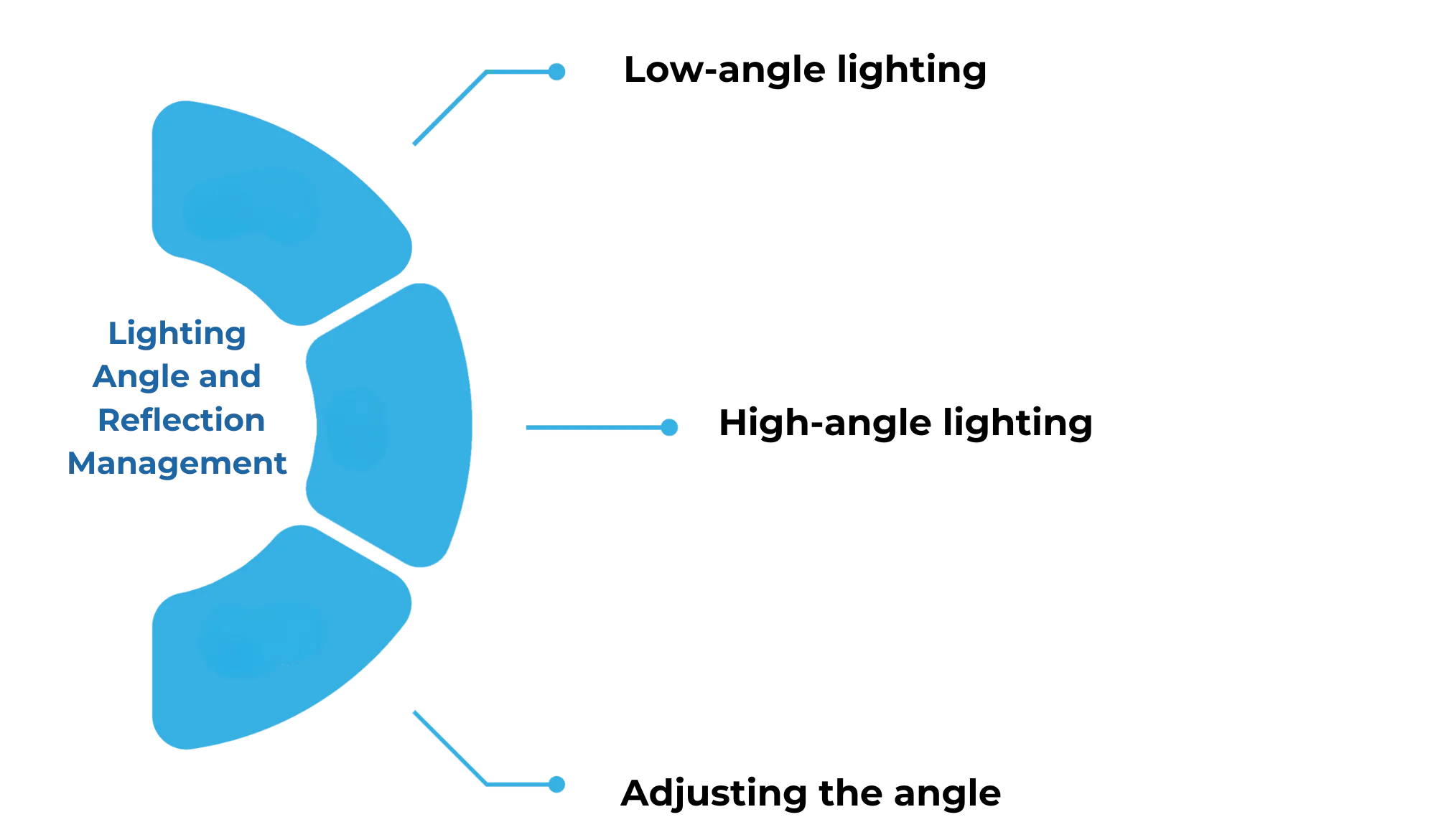

The angle at which light hits the object is crucial in machine vision systems. Improper lighting angles can result in reflection or glare, which can obscure details and lead to inaccurate analysis.

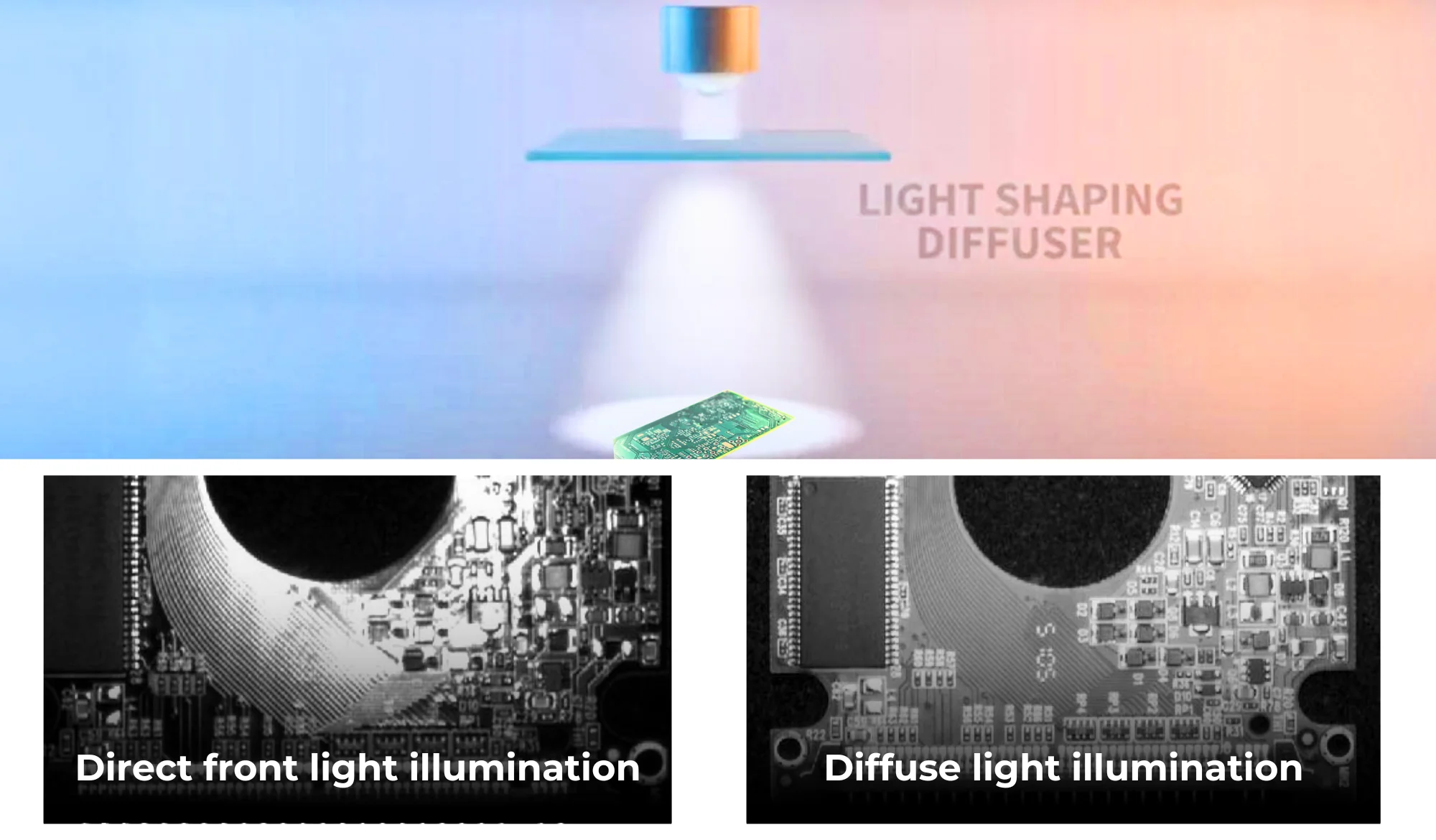

A diffuser is a translucent material used to scatter light, providing soft and even illumination across the object. It helps eliminate shadows and hotspots, which can otherwise interfere with the machine vision system's accuracy.

In machine vision, diffusers are essential when inspecting highly reflective surfaces. Without a diffuser, light reflections can create bright spots or glare, causing the camera to miss important details. A diffuser helps by spreading the light more evenly, reducing the harsh reflections and allowing the system to capture clearer, more uniform images.

Diffusers are particularly useful in:

©2025 Intelgic Inc. All Rights Reserved.