AI-Powered PCB Board Inspection Using Machine Vision and Robotic Imaging Systems

Book a call

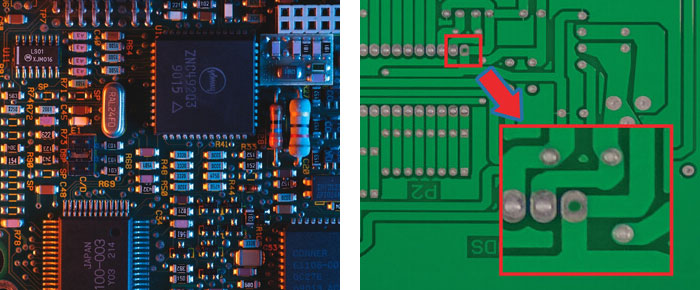

Printed Circuit Boards (PCBs) form the heart of modern electronic devices. Any defect or inconsistency in PCB manufacturing can lead to functional failure, high rejection rates, or field returns. As PCBs become more compact and densely populated with components, manual inspection becomes inefficient and error-prone.

To address this challenge, Intelgic provides a comprehensive PCB inspection automation system that integrates machine vision cameras, intelligent lighting, robotic imaging mechanisms, and powerful AI-based defect detection software.

Intelgic’s solution is built to handle all of these inspection challenges with exceptional accuracy and speed.

Intelgic’s system integrates hardware and software components to deliver seamless PCB inspection:

Proper lighting is critical for capturing defects:

Lighting is designed and positioned based on board texture, surface reflectivity, and inspection depth.

When it comes to inspecting large PCBs such as industrial control units, telecommunications boards, or server motherboards, a static imaging setup is often insufficient. These PCBs have a wide surface area and densely packed components that require high-resolution, close-range imaging—something a fixed camera cannot deliver uniformly across the board.

To overcome this challenge, Intelgic uses a robotic rail-based system where the camera and lighting assembly moves precisely along the X, Y, and Z axes. This motion is fully automated and controlled through a PLC (Programmable Logic Controller), offering highly accurate and repeatable positioning during the inspection process.

Intelgic’s robotic system enables three-axis movement:

X-Axis (Horizontal Travel)

Moves the camera and lighting system across the width of the PCB.

Y-Axis (Vertical Travel)

Covers the length of the board for complete surface imaging.

Z-Axis (Height Adjustment)

Adjusts the distance between the camera and PCB surface to optimize focus and field of view, especially useful for inspecting components of varying heights or fine details at different depths.

All three axes are precisely coordinated through PLC control, ensuring synchronized motion, safe travel limits, and accurate image capture positions.

PLC-Controlled Automation

Provides precise command over movement paths, speed, acceleration, and positioning. Integrates easily with the inspection workflow and safety systems.

Dynamic Z-Axis Focus Adjustment

Automatically changes the height of the camera system to focus on tall components, surface textures, or to switch between wide-area and zoomed-in imaging.

High-Speed, Low-Vibration Design

The rail system is engineered for smooth motion and image stability, preventing blurring during fast inspection cycles.

Programmable Scanning Patterns

Based on the PCB layout and inspection zones, custom scan paths can be programmed to efficiently cover all areas.

Camera Trigger Synchronization

The AI software coordinates with the PLC to trigger the camera only when it reaches a precise location, ensuring blur-free, high-resolution images.

Lighting System Integration

The lighting module moves along with the camera, maintaining optimal illumination across all imaging zones regardless of board size or surface topology.

This 3-axis robotic rail system is ideal for:

By moving the camera and lighting system in harmony along the X, Y, and Z axes, Intelgic ensures complete, high-quality imaging of any PCB surface, no matter how complex or expansive. The PLC-controlled robotic rail system provides unmatched precision, flexibility, and integration, making it ideal for next-generation PCB quality inspection.

In certain inspection workflows, especially where the camera remains fixed and high precision is required, Intelgic uses a motorized XY stage to move the PCB board itself under the camera. This automated platform enables highly controlled, repeatable motion along the X and Y axes, making it ideal for detailed inspection of small to mid-sized PCBs or high-density regions.

Intelgic’s inspection automation can seamlessly switch between robotic camera rails or motorized board stages depending on the product size, inspection resolution, and imaging architecture required. This flexibility allows manufacturers to choose the most efficient method for their production line while maintaining consistent quality and precision.

At the core of Intelgic’s solution is its powerful AI software trained for:

Component identification and classification

Component

counting

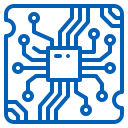

Defect detection and localization

Pixel-wise and region-wise analysis

Deviation analysis from design templates or BOM

Ensures all components are present in their correct location and orientation.

Identifies soldering issues, bridging, missing pins, lifted leads, discoloration, and substrate cracks.

Counts the exact number of resistors, capacitors, ICs, and other parts on each PCB.

Detects mismatches or missing components by comparing the live image with a reference template.

The software marks defect regions and calculates:

Supports multiple PCB types and layouts with individual inspection templates.

Intelgic’s system provides:

Intelgic’s solution is used in:

With increasing demand for precision and traceability in electronics manufacturing, AI-based PCB board inspection is essential for quality assurance. Intelgic’s robust system, combining machine vision, smart lighting, robotic imaging, and powerful AI software, delivers unmatched accuracy and flexibility across a wide range of PCB types.

Whether you’re inspecting small consumer boards or large industrial controller boards, Intelgic’s solution ensures zero-defect production with high-speed, automated verification.

©2025 Intelgic Inc. All Rights Reserved.