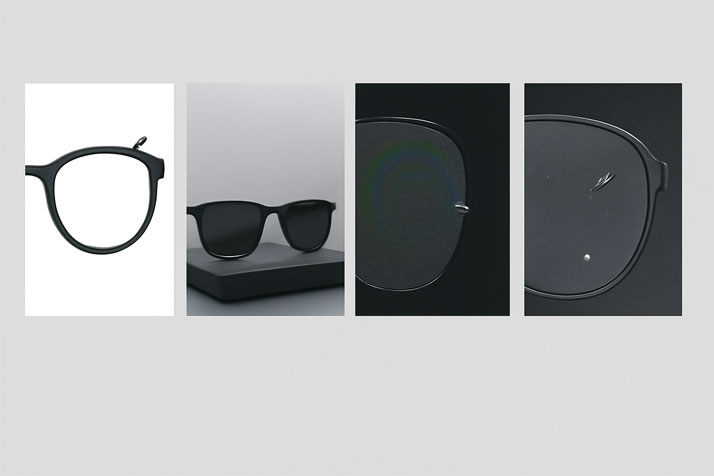

Style meets certified safety. Intelgic automates visual, cosmetic, and optical inspection of sunglass lenses—polycarbonate, CR‑39, high‑index, glass, TAC laminated, and film‑based polarizers—across surfacing, tinting, coating, edging, and final QC. Our turnkey system pairs precision optics, application‑specific lighting geometry, polarization metrology, and Live Vision AI to detect micro‑defects, verify tint and polarization, measure geometry, and issue a Digital Quality Certificate (DQC) for every PASS lens or matched pair.

Sunglass lenses are transparent, curved, and often coated or laminated. Typical hurdles include:

Glare hides sleeks, hairline scratches, pinholes, and stains.

Demand axis accuracy and high extinction; mis-alignment causes visual strain.

Uneven dyeing or mirrored layers create blotches/hot-spots.

Specular reflections confuse classic vision tools.

Refraction shifts apparent defect position; edge chips affect assembly.

Gradient and uniformity maps; early tint defects before coating

(mirror/AR/hard): glare‑suppressed pinhole/haze detection

Axis/efficiency measurement and left–right pair matching

Bevel chips, diameter, wedge, mark verification

Final QC & packaging

Full audit -> DQC with optical and cosmetic results

Ensure customers receive perfectly matched lenses:

Performance varies with material, coatings, base curve, and acceptance criteria. Intelgic tunes optics, lighting, motion, and AI to your targets.

Each PASS lens or pair receives a DQC that includes:

Yes. Cross‑polarized coaxial imaging isolates coating glare, while a rotating analyzer measures axis and extinction through the mirror stack.

Uniform dome illumination and calibrated colorimetry generate ΔE maps and gradient slope profiles for pass/fail decisions.

We estimate UV blocking with a controlled UV source/sensor module and record it in the DQC. For formal certification to specific standards, we can attach results from your off‑line instruments.

Yes. The pair‑matching module compares axis, tint ΔE, and geometry (diameter, CT/ET, wedge) and blocks packaging if out of tolerance.

We can run stimulus‑based darkening/clearing tests and log kinetics curves alongside standard cosmetic/geometry checks.

©2025 Intelgic Inc. All Rights Reserved.