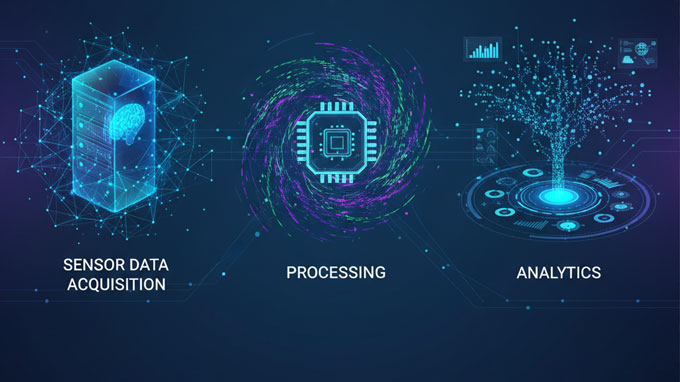

Custom Software for Sensor Data Acquisition, Processing & Analytics

Schedule a Demo

Turn raw signals into decisions. Intelgic builds bespoke software that reads data from virtually any sensor—image sensors, IR and heat sensors, color sensors, temperature and humidity, proximity and photoelectric sensors, encoders, load cells, vibration and acoustic sensors, and more—then cleans, fuses, analyzes, and visualizes it for humans and machines. From shop‑floor telemetry to executive dashboards, we engineer the entire

Camera/vision, IR, thermocouples/RTDs, photodiodes, ToF/LiDAR, colorimeters, spectrometers, ultrasonic, pressure, flow, torque, RFID, barcode/QR, proximity/inductive, encoders, photoelectric, vibration (IEPE), microphones, and more.

Deterministic edge collection with low latency, secure uplink to on‑prem or cloud analytics.

KPIs, trends, alerts, and Digital Quality Certificates (DQC) for traceability.

Designed for harsh environments; integrates with PLCs, MES/ERP, SCADA, CMMS.

Hardware selection guidance, software engineering, dashboards, APIs, and support.

Area/line‑scan, industrial RGB/Mono, NIR/SWIR, thermal.

Thermocouples, RTD, IR pyrometers, thermal arrays.

Color sensors, spectrometers, printing CMYK validation.

Rotary/linear for speed/position synchronization.

IEPE accelerometers, MEMS mics for bearing/fan health.

Humidity, pressure, flow, gas.

Vision + sensors to detect defects, verify assembly, confirm labels/prints.

Temperature/pressure/flow profiles with SPC and alarms.

Vibration + thermal + current draws for early anomaly alerts.

Part‑wise records, Digital Quality Certificates with evidence.

Compare region‑wise CMYK/ΔE against master references.

Yes—OPC UA/DA, Modbus, MQTT, REST, and vendor SDKs are supported.

Absolutely. We align vision data with encoders/IR/others for richer context.

Both. Many clients choose hybrid edge + on‑prem or edge + cloud.

We can compute region‑wise CMYK, ΔE/ΔE2000, and compare against your master references.

Thresholds, rules, AI anomalies; notifications via emails/SMS/WhatsApp and PLC/robot outputs.

©2025 Intelgic Inc. All Rights Reserved.