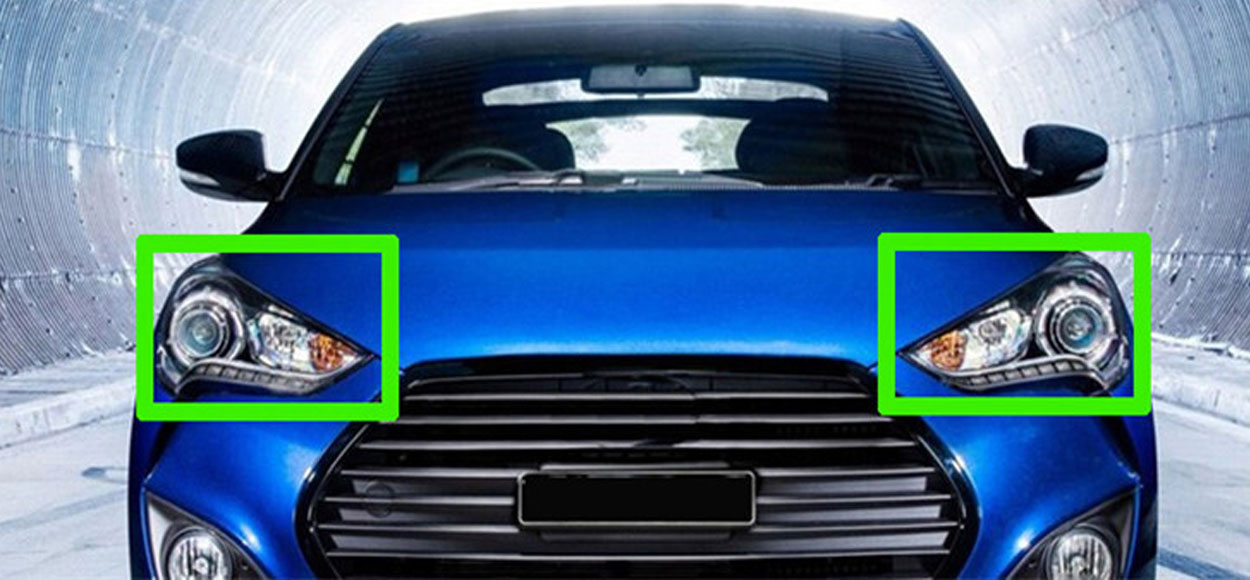

Automated Headlamp and Taillamp Inspection Using Machine Vision AI

Book a call

Headlamps and taillamps are critical for both vehicle safety and aesthetics. Even minor defects can affect light projection, visual appeal, and regulatory compliance.

Our AI-powered vision system detects a wide range of surface and internal defects with precision.

Imperfections on the lens or housing that affect clarity or appearance.

Foreign particles trapped inside the housing during assembly.

Uneven joints, gaps, or overflow in sealing areas.

Caused by improper cooling or material flow during molding.

A turnkey system tailored to the challenges of inspecting transparent, reflective, and multi-layered automotive lighting components.

Machine Vision cameras capture high-detail images of the lens surface, internal structures, and assembly points for accurate defect analysis.

Custom-configured lighting modules reduce glare, reveal fine scratches, and highlight internal contamination or deformation.

Robotic arms move cameras and lights dynamically around the headlamp or taillamp, enabling full part coverage.

Multiple camera stations capture images from top, front, side, and diagonal angles for comprehensive inspection.

AI software detects defects, logs measurements, and classifies parts in real time with minimal latency.

Operates seamlessly in both inline production environments and offline quality control cells.

Our advanced system intelligently manages multi-material imaging, reflection control, and image stitching to ensure complete surface analysis of even the most complex automotive lighting components.

Automatically detects and adapts to different materials—clear plastic, black reflective elements, coated surfaces—within the same part.

Captures multiple images from different angles with overlap calculation to ensure no area is missed.

Identifies micro-defects such as scratches, sink marks, air bubbles, and dust particles across all material zones.

Our system integrates seamlessly with your production line to deliver fast, accurate results.

Lamp arrives at inspection station via conveyor or robot

Robotic system captures images from all required angles

Software processes images and detects defects in milliseconds

System classifies part and triggers pass/fail action

Transform inspection data into actionable insights for continuous improvement.

Intelgic's AI-powered inspection solution ensures that every lamp you deliver is flawless, compliant, and ready for the road.

©2025 Intelgic Inc. All Rights Reserved.