Customized Imaging Solutions for Manufacturing

Get customized imaging based on your needs.

Book a call

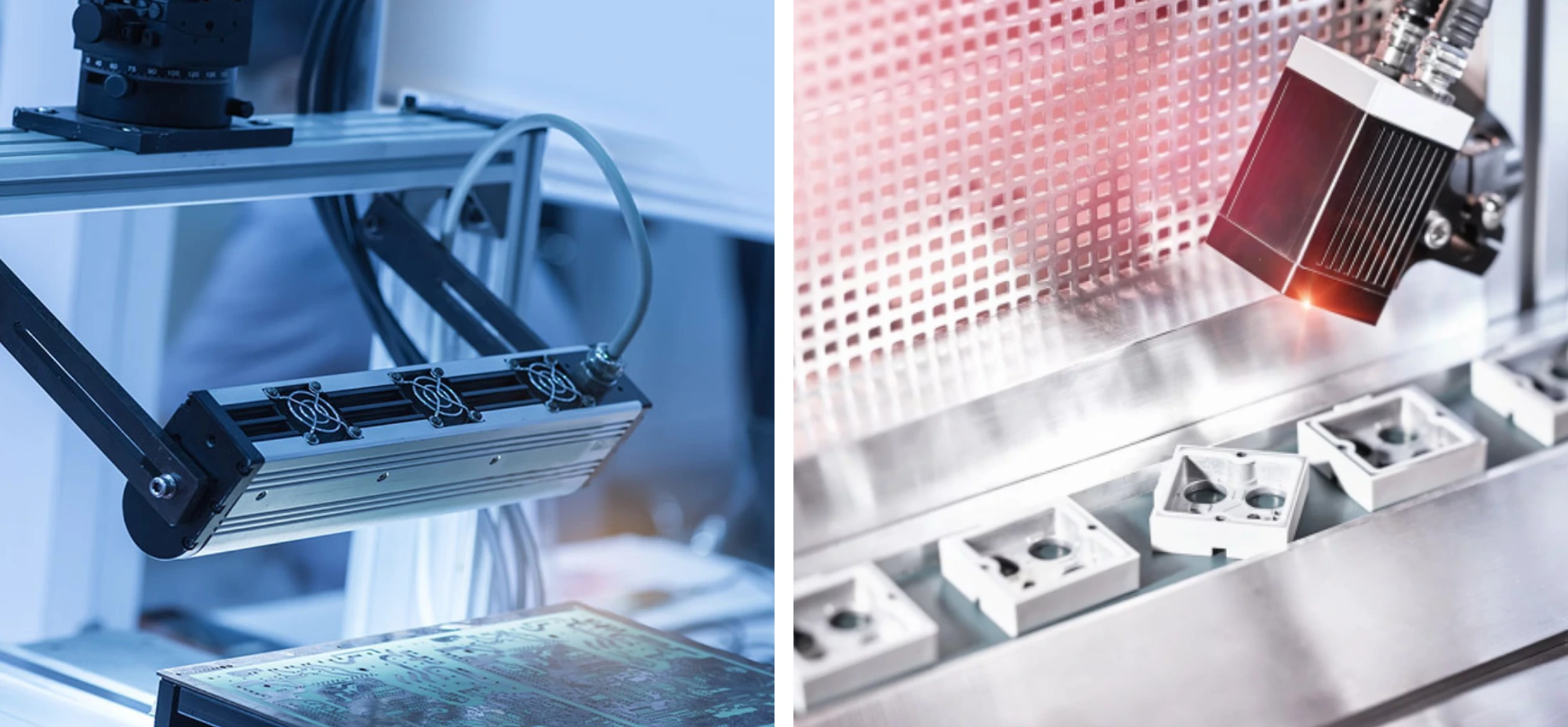

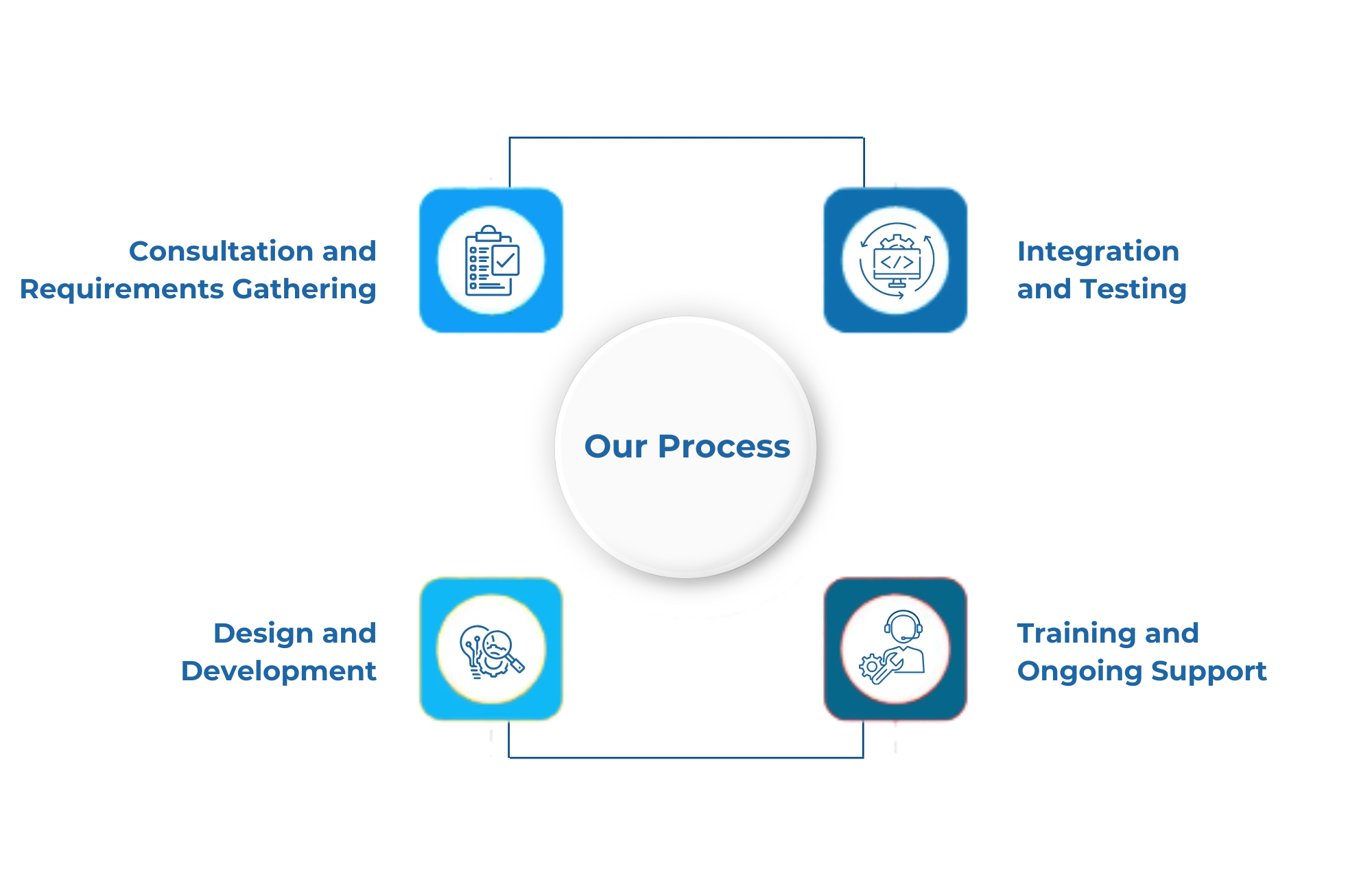

At Intelgic, we specialize in providing customized imaging solutions tailored to the unique needs of manufacturing environments. From custom-designed CIS (Contact Image Sensor) modules to advanced machine vision cameras, our solutions are crafted to meet specific inspection, quality control, and production monitoring requirements. Our team combines expertise in imaging technology with a deep understanding of manufacturing processes to deliver high-performance, reliable imaging solutions that integrate seamlessly into your production line.

Standard imaging solutions often fail to address the specialized needs of complex manufacturing processes.

With customized imaging solutions, you gain:

Intelgic offers a range of imaging solutions, from flexible CIS modules to custom-designed machine vision cameras, each tailored to meet the exact specifications of your manufacturing process.

Contact Image Sensors (CIS) are ideal for applications that require high-resolution, continuous image capture across a specific length or area. We provide customized CIS modules designed to match your specific requirements, offering customization options such as:

Our CIS modules are perfect for applications where surface inspection, product tracking, or high-resolution scanning of moving products is required. With adjustable length and sensor configurations, our CIS modules provide an efficient, scalable solution for a wide range of manufacturing processes.

For more complex or unique imaging requirements, we design and develop custom machine vision cameras. Our cameras are engineered for precise, high-quality imaging in challenging environments and can be tailored to:

Our machine vision cameras provide unparalleled image clarity and resolution, making them ideal for high-precision inspections in industries such as electronics, automotive, pharmaceuticals, and food processing.

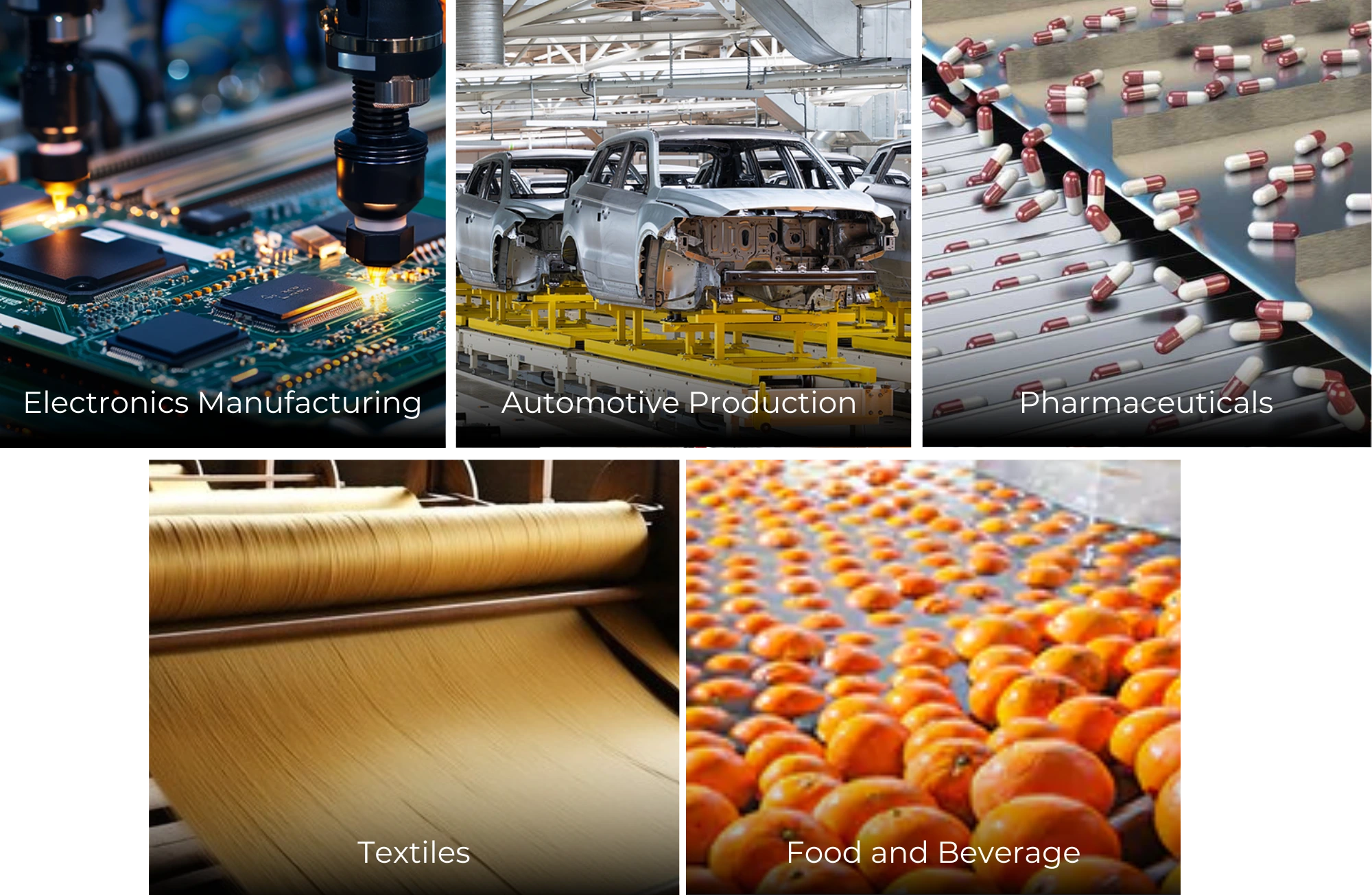

Our customized imaging solutions serve a wide range of manufacturing industries, each with specific needs and challenges:

Intelgic’s customized imaging solutions bring precision, adaptability, and efficiency to your quality control process. Our CIS modules and machine vision cameras are designed to meet the unique challenges of your production line, offering tailored solutions that enhance inspection accuracy and operational efficiency.

Contact us today to learn how we can help you achieve superior quality control with a customized imaging solution designed specifically for your manufacturing needs. Let’s work together to create a system that ensures the highest standards of quality and performance for your products.

©2025 Intelgic Inc. All Rights Reserved.