Microscopic Inspection Automation using Machine Vision AI

Revolutionizing quality assurance with AI-powered automated optical inspection systems for micron-level defect detection.

Book a call

Industries that rely on microscopic inspection for quality assurance often face challenges with manual processes. From medical devices to microelectronics, inspecting components under a microscope can be labor-intensive, time-consuming, and prone to human error.

Intelgic's Microscopic Inspection Automation system revolutionizes this process by leveraging AI-powered technologies, delivering consistent, accurate, and efficient defect detection.

Results vary based on the operator's expertise and fatigue. Subjectivity in defect classification leads to inconsistent quality.

Inspecting components manually under a microscope is a slow process that increases production cycle times and creates bottlenecks.

High labor costs and limited throughput hinder scaling operations to meet increasing production demands.

Micron-level defects are often missed due to human limitations in concentration and visual acuity.

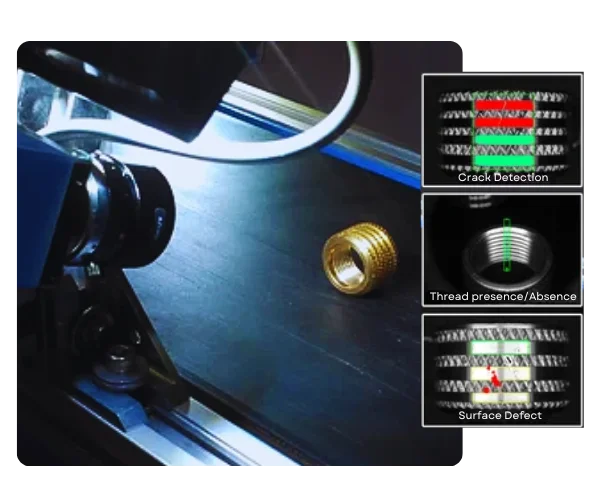

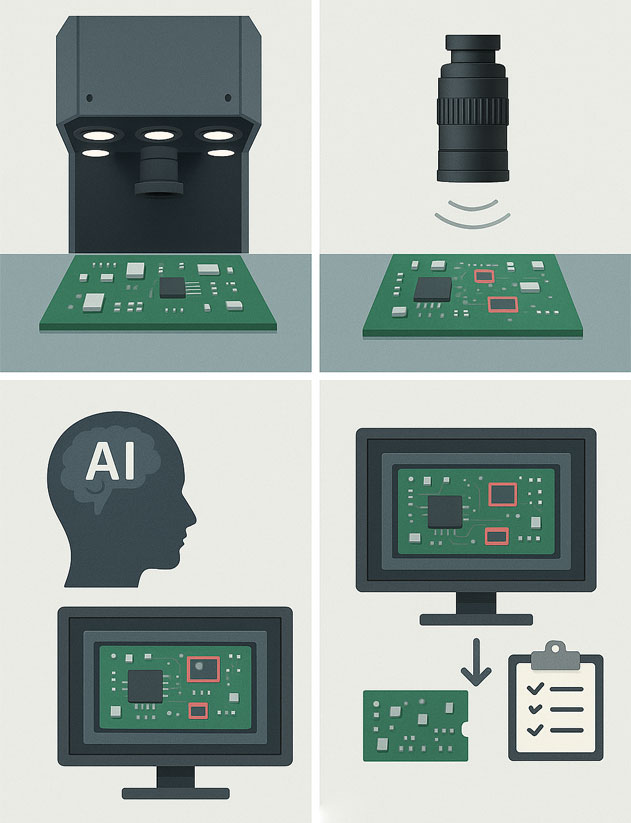

Our system automates the microscopic inspection process by combining advanced imaging hardware, tailored lighting, and state-of-the-art AI for faster, more reliable, and scalable quality assurance workflows.

Industrial-grade cameras capture detailed images of microscopic components with interfaces like GigE, USB, and 10 GigE for seamless data transfer.

Tailored to the target product, defect size, and working environment with options including fixed focal, telecentric, and autofocus lenses.

Built-in lighting ensures consistent illumination with ring lights, coaxial lights, and backlighting options adjustable in real-time.

Proprietary AI software processes images to detect defects, identifying surface irregularities, micro-cracks, and contamination with continuous learning.

Components are positioned under the automated optical inspection (AOI) system. Lighting and camera configurations are optimized based on the target object.

High-resolution images are taken, either as a single shot or multiple shots for complex components to ensure comprehensive coverage.

The AI processes the captured images, analyzing every pixel for potential defects. Defects are categorized and visualized on an intuitive interface for review.

Results are logged for traceability, and defective components are flagged for removal. Data insights help optimize production processes and improve yield.

Intelgic's Microscopic Inspection Automation is ideal for precision industries requiring micron-level quality control.

Ensuring precision in implants, surgical tools, and diagnostic components with micron-level accuracy.

Detecting defects in PCBs, semiconductors, and microchips where even microscopic flaws can cause failures.

Inspecting small parts like connectors, sensors, and electronic components for reliability and safety.

Maintaining the integrity of mission-critical parts at a microscopic level for flight safety.

Verifying the quality of capsules, powders, and coated surfaces for consistent medication delivery.

Ensuring flawless assembly of intricate watch components where precision is paramount.

Detect defects as small as a few microns with high precision that surpasses human capabilities.

Automates repetitive tasks, reducing inspection times significantly while maintaining accuracy.

Eliminates variability caused by human inspection with standardized, repeatable processes.

Handles high-volume production without compromising quality or requiring additional labor.

Reduces labor costs and minimizes losses due to defective products reaching customers.

Provides actionable data to enhance production processes and continuous quality improvement.

Proven experience in designing and deploying inspection systems for diverse industries with specialized solutions.

Tailored to meet the specific needs of your application, environment, and defect requirements with flexible configurations.

Our AI software is continuously evolving to detect new defect types and patterns through machine learning.

From setup to maintenance, Intelgic offers end-to-end support to ensure optimal system performance throughout its lifecycle.

Intelgic's Microscopic Inspection Automation system is your solution for efficient, accurate, and scalable quality assurance. By automating manual processes, you can achieve higher throughput, lower costs, and unparalleled consistency.

Contact us today©2025 Intelgic Inc. All Rights Reserved.