Live Vision: Automate Quality Inspection Process using state of the art AI, specially designed for defect detection.

Book a call

Intelgic's Live Vision software is an advanced inspection automation solution designed to seamlessly integrate with machine vision cameras, CIS (Contact Image Sensors), customized imaging devices, and other sensors, including laser sensors, to detect defects, measure dimensions, and automate complex inspection processes in manufacturing.

Powered by state-of-the-art AI, Live Vision achieves nearly 100% accuracy in defect detection, providing manufacturers with a highly reliable and consistent quality control tool. Equipped with a GPU-based controller and frame grabber, the software processes live sensor outputs in near real-time and supports integration with external systems, such as PLCs, through Ethernet (TCP/IP) connectivity.

Live Vision is powered by cutting-edge AI and machine learning algorithms, specifically designed for defect detection and inspection automation. This advanced AI engine ensures nearly 100% accuracy in identifying defects and anomalies, setting a new standard in quality control.

Live Vision is highly scalable and can adapt to new products, defect types, and surface anomalies with ease. Its AI requires minimal data for training, making it quick to learn new inspection tasks and support changes in production needs.

Tailored to meet unique manufacturing requirements, Live Vision can be further customized to handle complex inspection processes and adapt to any manufacturing environment, sensors etc. regardless of complexity.

The software supports smooth integration with external systems such as PLCs and other automation platforms, making it easy to incorporate Live Vision into existing production lines and workflows.

While all inspection processing occurs locally on the GPU-based controller for fast, reliable analysis, Live Vision also supports cloud connectivity. This enables access to a cloud-based analytics dashboard, allowing teams to review and analyze inspection data remotely.

Live Vision delivers real-time analysis, processing live sensor outputs at high speeds. This ensures that defects are detected instantly, keeping up with the pace of modern manufacturing environments.

Live Vision supports a wide range of sensors, including machine vision cameras, CIS (Contact Image Sensors), laser sensors, and customized imaging devices, enabling it to tackle a diverse set of inspection tasks.

By leveraging powerful AI algorithms and high-performance hardware, Live Vision achieves high levels of accuracy in defect detection, dimension measurement, and inspection consistency, ensuring reliable quality control.

At Intelgic, we understand that each manufacturing environment has specific requirements. Live Vision is fully customizable to suit your unique inspection processes, allowing manufacturers to tailor the software for specific inspection tasks, defect types, or measurement standards. Whether you need custom workflows, sensor integrations, or specialized AI training, our team works closely with you to deliver a fully optimized solution that aligns with your operational demands.

One of Live Vision’s standout features is its scalability and adaptability. The software’s AI can be trained with minimal data, requiring only a few images to learn new product profiles or defect types. This rapid adaptability allows manufacturers to introduce new products into the inspection process seamlessly without lengthy training or reprogramming.

Live Vision is compatible with a wide range of cameras, making it a versatile solution for various inspection needs:

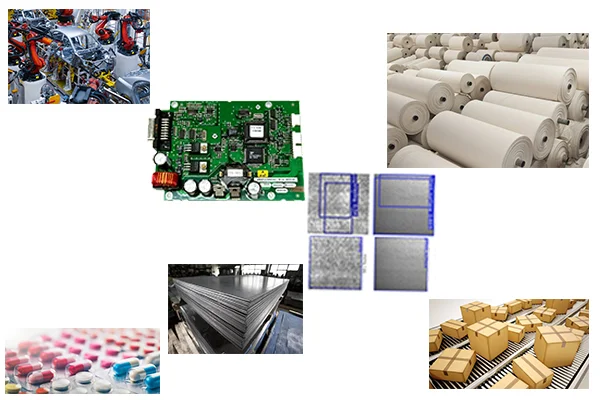

Live Vision’s versatility makes it suitable for a broad range of industries and applications:

Explore how Intelgic’s Live Vision software can elevate your manufacturing quality control with accurate, fast, and highly customizable inspection solutions. Our team is here to discuss your specific needs and provide a tailored approach to defect detection and inspection automation.

Contact us to schedule a demo or for more information on how Live Vision can transform your manufacturing quality control processes.

©2025 Intelgic Inc. All Rights Reserved.