We have the right camera for your product defect detection automation solution

Book a call

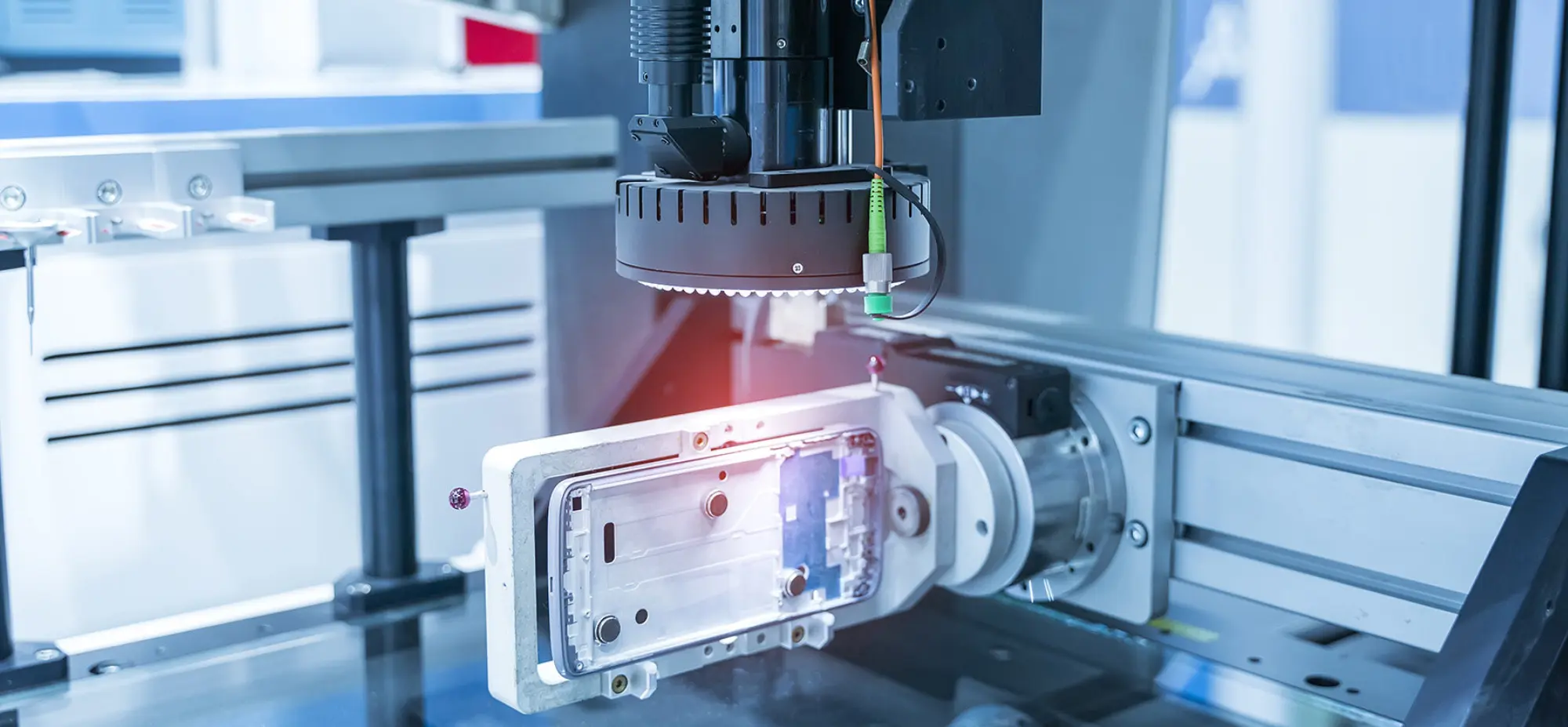

Selecting the right camera and its components is essential for effective defect detection and automating the visual inspection process. We consider various factors—such as defect size, working distance, the product or material being inspected, product dimensions, inspection area, and the speed at which products move on a conveyor belt or roller—to ensure the optimal camera choice for your quality inspection automation.

Line scan cameras are specialized imaging devices designed to capture high-resolution images of products as they move continuously through a production line. Line scan cameras capture images one line at a time, stitching together a seamless, detailed image of long or cylindrical objects.

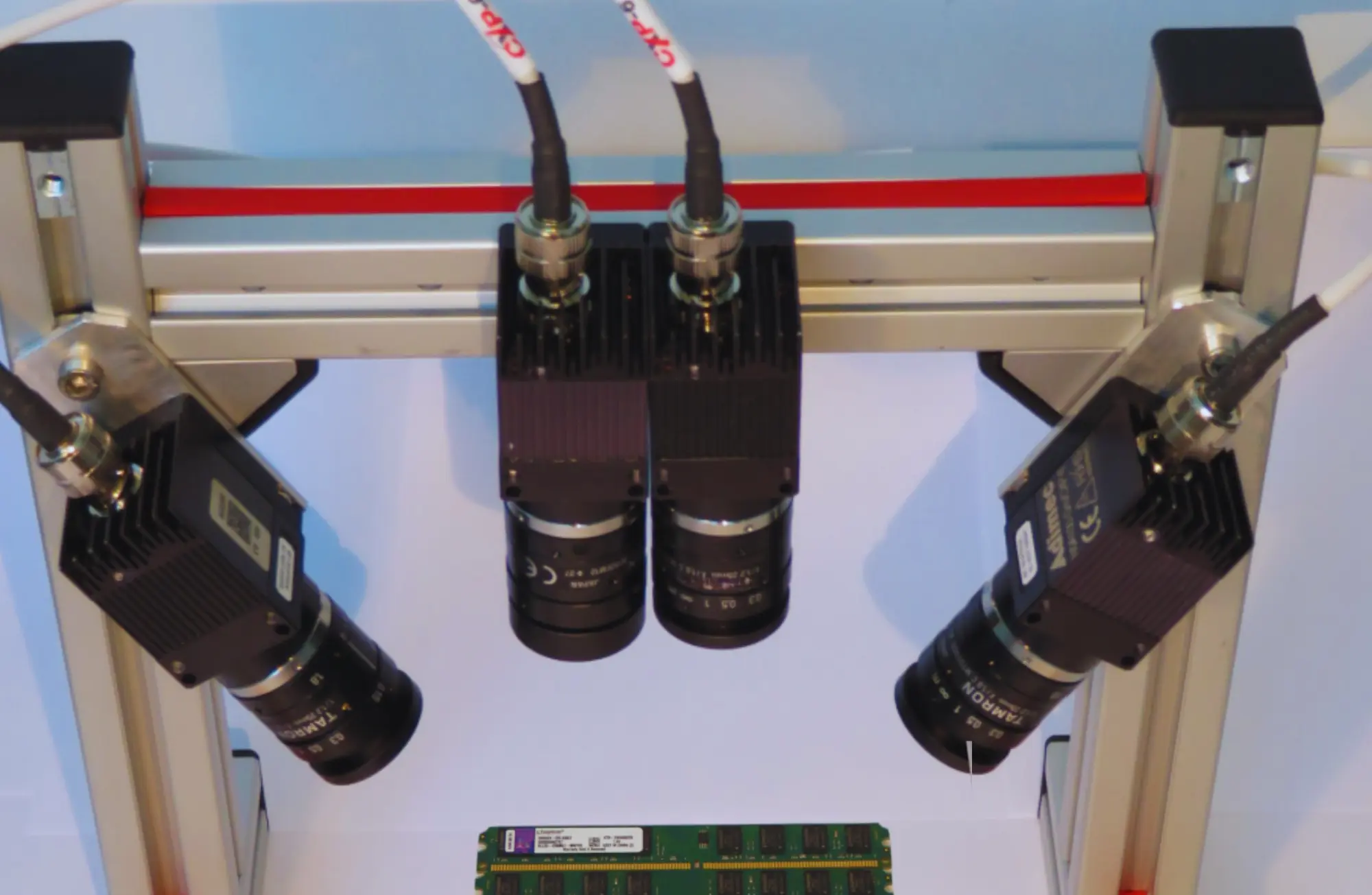

Area scan cameras capture full-frame images in a single exposure, making them ideal for applications where the entire surface of an object needs to be inspected at once. Area scan cameras are used in environments where objects are stationary and not moving.

GigE cameras are industrial cameras that utilize the Gigabit Ethernet (GigE) interface to provide high-speed data transfer over long distances to the controller. GigE cameras can be easily integrated into existing network infrastructures, providing a cost-effective solution for high-performance imaging.

USB 3 cameras utilize the USB 3.0 interface, offering fast data transfer rates and easy integration with a wide range of systems. These cameras are used where defect sizes are smaller and products are not moving at high speeds through conveyor belts. USB 3 cameras can be both line scan and area scan cameras.

Cameras equipped with the Camera Link interface are known as Camera Link cameras. These high-performance imaging devices are specifically designed for detecting smaller even microscopic defects(.1mm) in products that move quickly through conveyor systems. Typically, these cameras are line scan cameras, making them ideal for applications requiring precise and rapid inspection of fast-moving objects.

CoaXPress cameras are high-performance imaging devices that utilize the CoaXPress interface, offering extremely high data transfer rates and long-distance transmission capabilities. These cameras are designed for applications that require ultra-high resolution and rapid image acquisition, making them ideal for inspecting fast-moving objects and capturing fine details.

Contact Image Sensor (CIS) cameras are specialized imaging devices designed for applications that require high-resolution scanning and microscopic defect detection. These cameras use a linear array of sensors positioned in close proximity to the object, allowing them to capture detailed images with consistent illumination. CIS cameras are particularly effective in inspecting flat or continuous surfaces where uniformity and precision are critical.

©2025 Intelgic Inc. All Rights Reserved.