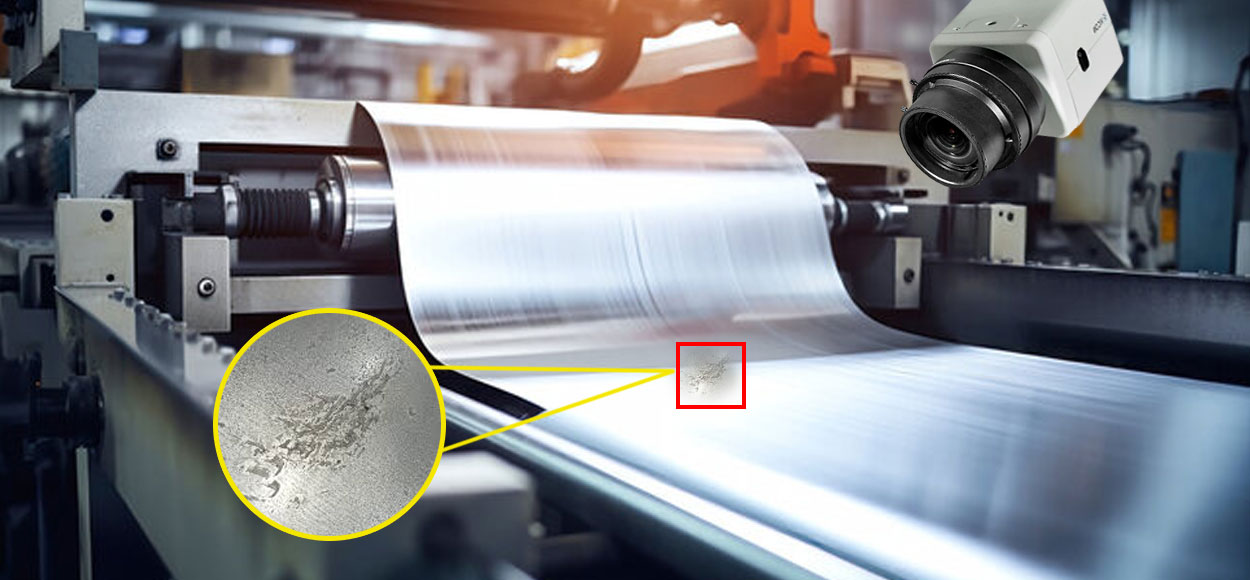

Metal Sheet Inspection System Powered by AI & Line Scan Vision

Ensure flawless metal surface quality with Intelgic’s real-time inspection solution.

Book a call

Metal sheets used in automotive, construction, appliance manufacturing, and industrial applications require defect-free surfaces for performance and aesthetic integrity. Defects like scratches, dents, pits, pinholes, and corrosion often occur during production, handling, or processing.

Intelgic delivers a fully automated machine vision solution to inspect high-speed, wide-format metal sheets with precision and consistency—ensuring 100% inspection coverage at speeds ranging from 10 MPM to 80 MPM.

Intelgic delivers a fully integrated metal sheet inspection system that includes:

High-performance line scan cameras

Custom-designed lighting solutions

Mounting hardware and conveyor-compatible installation

AI-based software for real-time defect detection

Reporting and analytics dashboard

On-site installation, calibration, and training

Our expert team will install, calibrate, and demonstrate the system at your facility to ensure seamless performance.

Contact Intelgic today to schedule a demo or request a technical consultation.

©2025 Intelgic Inc. All Rights Reserved.