Injectors with AI-Powered Inspection

Automated inspection system for injector pins, nuts, and assemblies — ensuring flawless alignment, micro-defect detection, and world-class reliability.

Book a call

Precision Inspection for Pins, Nuts & Injector Assemblies

Fuel injectors are the heart of modern engines. A micron-level defect in a pin, nut, or sealing surface can cause leakage, poor fuel atomization, and engine failure. Manual inspection under microscopes is inconsistent and operator-dependent. Intelgic’s Machine Vision AI Fuel Injector Inspection System eliminates these challenges by delivering 100% automated, inline quality inspection of fuel injector components.

State-of-the-art industrial imaging hardware for flawless precision

20–65 MP for capturing tiny details with exceptional clarity

Ensure distortion-free images for accurate measurements

Coaxial, low-angle, and dome lighting for optimal surface illumination

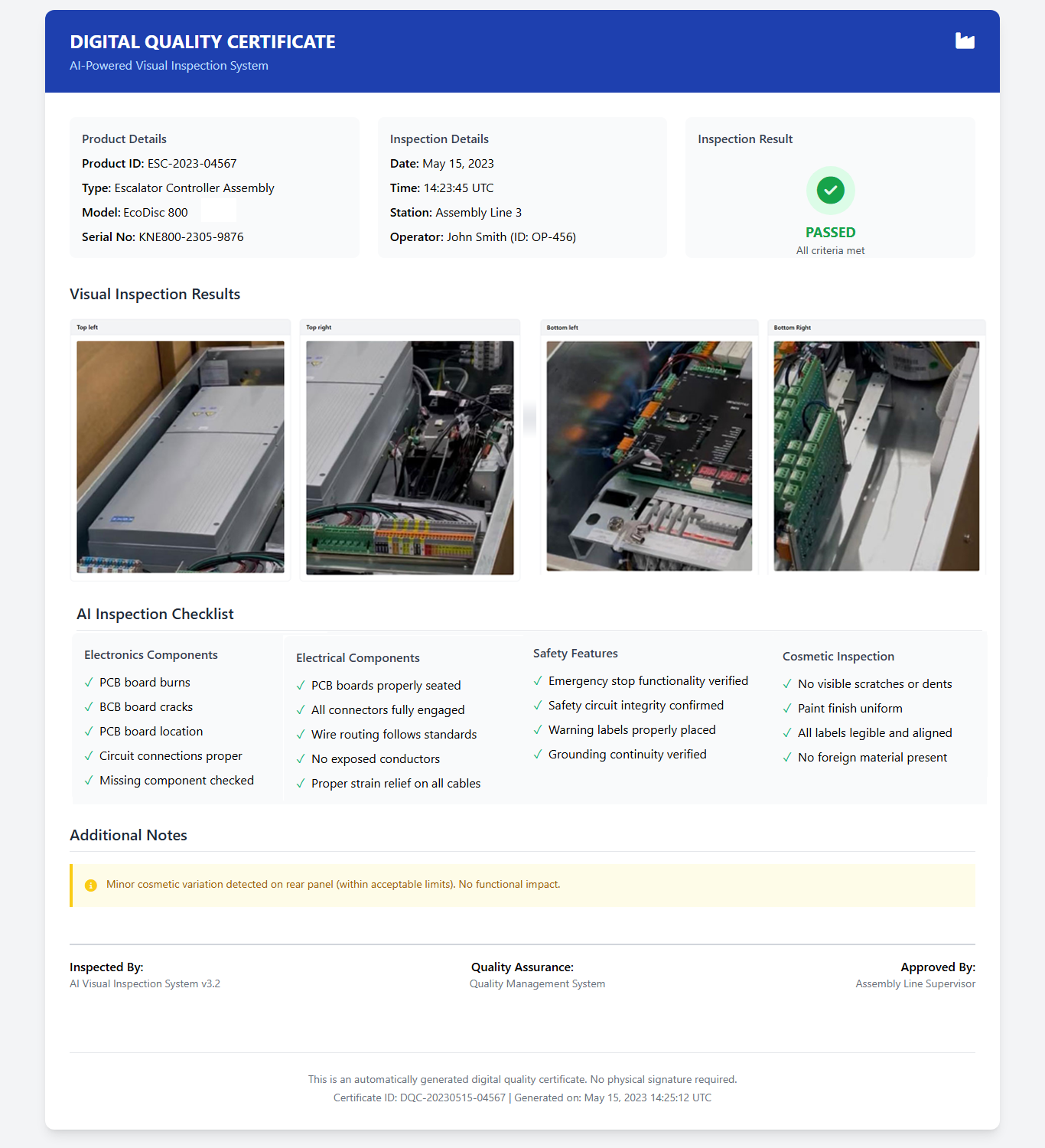

Every injector generates a detailed inspection report with:

Zero-defect manufacturing assurance

Higher productivity — replacing slow microscope inspection

Reduced warranty claims & rework

Compliance with IATF 16949 / ISO standards

Scalable across multiple injector models

Intelgic’s Fuel Injector Inspection System brings AI, machine vision, and robotic automation together for unmatched precision.

Contact Us Today to schedule a demo and discover how you can achieve 100% quality control in fuel injector manufacturing.

©2025 Intelgic Inc. All Rights Reserved.