Intelgic’s machine vision solution combines industrial-grade cameras, advanced optics, specialized lighting, custom electromechanical setups, and our powerful Live Vision AI software to detect defects from 10 microns to 10 millimeters. Whether you’re inspecting complex surfaces, fast-moving parts, or transparent materials, our system delivers real-time detection, AI-based classification, and cloud-based analytics to help you eliminate defects and optimize production.

At Intelgic, we don’t just supply software or cameras — we deliver a comprehensive, fully integrated machine vision system tailored to your unique inspection requirements.

Whether you’re dealing with shiny metallic surfaces, transparent components, curved geometries, or fine scratches as small as 10 microns, Intelgic’s turnkey solution is engineered to meet the most demanding visual inspection needs.

We work closely with your team to design, deploy, and support a solution that integrates seamlessly with your production line — minimizing human error, maximizing accuracy, and accelerating defect resolution.

Live Vision AI is Intelgic’s proprietary software platform designed to power the visual inspection process — from defect detection to data analytics. It enables your production line to move faster, detect smaller issues, and generate actionable insights that improve product quality and reduce manufacturing waste.

Detects defects as small as 10 microns, up to 10 millimeters — including scratches, dents, discoloration, misalignments, and material inconsistencies.

Train your own AI models using labeled datasets collected from your products. Easily distinguish between OK and NG samples and continuously improve accuracy.

Create inspection templates (“recipes”) for different products, product lines, or variants. Switch between them effortlessly during changeovers or batch transitions.

Identify the type of defect, its location, and measure its size and affected region in real time. Define your acceptance criteria and auto-reject or flag non-conforming products.

Break the image into defined zones or grids to isolate defect-prone areas, enabling zonal analysis and pixel-level feature extraction.

Intuitive HMI for live defect visualization, status updates, and operator feedback. All inspection data is saved with timestamps and image references.

With Live Vision AI, you’re not just detecting defects — you’re building a smarter, self-improving inspection system that adapts to your products and evolves with your process.

At the heart of every Intelgic vision system is a carefully engineered imaging stack — optimized for your product type, defect profile, and environmental conditions. We select and configure every component to ensure maximum image clarity, consistency, and defect visibility.

We have a wide range of high-resolution industrial cameras and based on the product, defects, materials, manufacturing and inspection process we choose the right imaging setup. We have all types of camera including:

Precision optics tailored to each inspection use case:

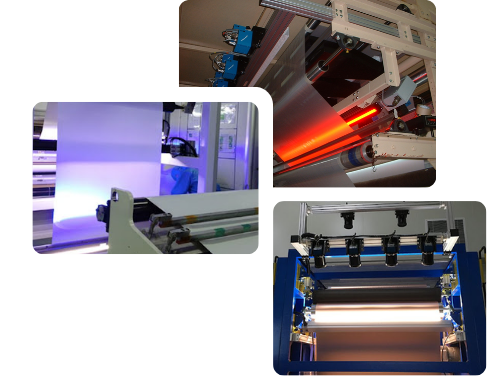

Lighting is the most critical component in machine vision imaging. It controls contrast, suppresses glare, highlights defects, and makes invisible issues visible. Intelgic carefully selects the optimal lighting based on product material, surface finish, and defect characteristics.

Reveals fine surface scratches, cracks, or dents on shiny or reflective objects by projecting light directly onto the object through a beam splitter, ensuring near-perfect vertical illumination.

Provides highly diffuse and uniform illumination, eliminating harsh shadows and reflections on curved or uneven surfaces by scattering light across a hemispherical dome.

Delivers directional lighting to highlight surface texture, raised features, or small edges by casting shadows from a specific angle.

Places light source behind the object to create high-contrast silhouettes, enabling precise edge detection, profile measurements, and inspection of transparent or translucent materials.

Surrounds the camera with a circular light source to deliver uniform, shadow-free illumination on flat or low-profile objects.

Uses multiple light angles simultaneously to eliminate shadows, especially helpful for complex geometries or 3D parts.

Illuminates the object from a low grazing angle to make tiny surface imperfections like scratches, chips, or dust appear as bright features against a dark background.

Illuminates the object directly from above, capturing reflected light and emphasizing color, contrast, and shape.

Intelgic also tailors the wavelength of light (color) to enhance specific surface features or material responses:

Lighting design is not one-size-fits-all — it’s a science. Intelgic uses simulation, prototyping, and field testing to ensure the right lighting technique and wavelength are used for each inspection point in your production line.

For dynamic, flexible, and multi-angle inspection, Intelgic designs:

For applications requiring rapid autofocus and inspection at varying heights or depths, we integrate:

Every imaging configuration is tested and fine-tuned to your production line’s physical and visual requirements — ensuring unmatched reliability and repeatability, even in demanding industrial environments.

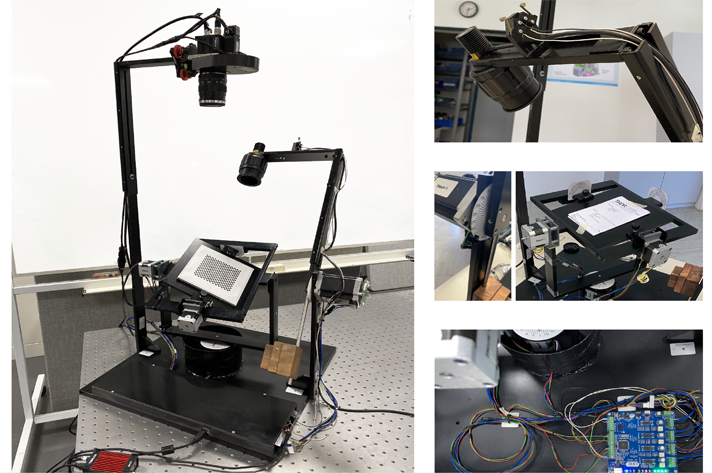

For industries where precision is measured in microns — such as semiconductors, medical devices, optics, and fine electronics — Intelgic offers advanced microscopic inspection automation. These systems are built to detect surface and structural defects smaller than 10 microns, which are often invisible to the human eye and even standard vision systems.

Using high-magnification optics, advanced imaging sensors, and AI-powered classification, Intelgic delivers repeatable, automated microscopic inspection for highly sensitive and complex components.

Intelgic’s microscopic inspection solution brings lab-grade accuracy to the production floor, delivering speed, consistency, and AI-based insight — without manual microscopy or bottlenecks.

Intelgic’s machine vision system doesn’t stop at detecting defects — it turns every inspection into meaningful analytics that help improve your product quality and manufacturing efficiency over time.

All inspection data captured by Live Vision AI is securely uploaded to the on-prem server or to the cloud, where it is organized, visualized, and analyzed through a powerful dashboard. This gives you real-time and historical insights into what’s failing, why it’s failing, and how frequently it’s happening.

By connecting vision inspection to the cloud, Intelgic enables your team to move from detection to prevention — using data to optimize processes, reduce downtime, and enhance yield.

Intelgic’s machine vision AI plays a critical role at the packaging line — ensuring that only correctly sealed, properly assembled, and fully packed products leave your facility. With real-time detection of seal defects, missing items, or misalignments, our system helps eliminate costly shipping errors and reduce warranty claims.

By automating inspection at the final stage, Intelgic ensures that your packaging meets both technical and customer expectations.

Intelgic’s machine vision systems are not just for detecting visual defects — they are also engineered for precise, non-contact dimensional measurement of industrial components and materials.

Whether you need to measure the length, width, height, diameter, hole position, edge distance, angle, or profile tolerance, our system delivers reliable, micron-level accuracy using high-resolution imaging and smart algorithms.

Intelgic’s dimension measurement system provides not only inspection accuracy, but also automated judgment and analytics, helping you maintain tolerance control without manual intervention.

All results can be logged, reported, and visualized in our analytics platform, with integration into PLCs or MES for pass/fail decision-making.

Not all products are flat, matte, or consistent — and Intelgic’s machine vision system is specifically engineered to handle the tough ones. Whether your parts are transparent, reflective, curved, variable in shape, or moving at high speeds, we design inspection systems that adapt to your production realities.

Every Intelgic solution is engineered to fit your product, not the other way around — ensuring reliable inspection, even for the most demanding manufacturing scenarios.

©2025 Intelgic Inc. All Rights Reserved.