Line Scan Cameras: Precision Imaging for Continuous Inspection

Book a call

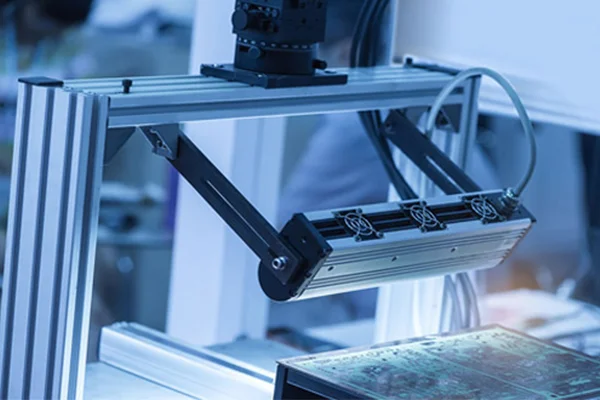

Line scan cameras are specialized imaging devices designed to capture high-resolution images of objects as they move continuously through a production line. Unlike traditional area scan cameras that capture an entire image in a single frame, line scan cameras capture images one line at a time, which are then stitched together to create a seamless, detailed image. This unique capability makes line scan cameras the preferred choice for inspecting long or cylindrical objects, as well as continuous materials like textiles, paper, and metal sheets.

In high-speed manufacturing environments, the need for precise and uninterrupted imaging is critical. Line scan cameras excel in applications where consistent, high-quality images are required across large areas or over extended lengths of material. They are particularly effective in detecting linear defects, ensuring that every detail of the product is thoroughly inspected.

Line scan cameras are used across various industries for a multitude of applications. Their ability to provide high-resolution, continuous imaging makes them indispensable for quality control and defect detection in the following areas:

At Intelgic, we understand that every manufacturing process is unique. That's why we offer customizable line scan camera solutions tailored to your specific needs. Whether you're dealing with high-speed production lines, intricate materials, or complex inspection requirements, our experts work with you to select the right camera specifications, lenses, lighting, and integration options.

We also provide full support for integrating line scan cameras with your existing systems, ensuring a smooth transition and minimal disruption to your operations. Our solutions are designed to enhance your quality control processes, reduce waste, and improve overall product quality.

Ready to enhance your inspection process with line scan cameras? Contact Intelgic today to learn more about our line scan camera solutions and how they can be tailored to meet the demands of your specific application. Our team of experts is here to help you achieve the highest standards of quality and efficiency in your production line.

Contact Us©2025 Intelgic Inc. All Rights Reserved.