Automate measurement and diameter inspection process in your manufacturing lines using AI driven contactless machine vision system

Book a call

In precision manufacturing, accuracy in measurement and diameter is crucial for quality control. Intelgic’s machine vision AI system offers an automated solution for high-speed, non-contact measurement and diameter inspection, ensuring consistent product quality and reducing the chance of human error.

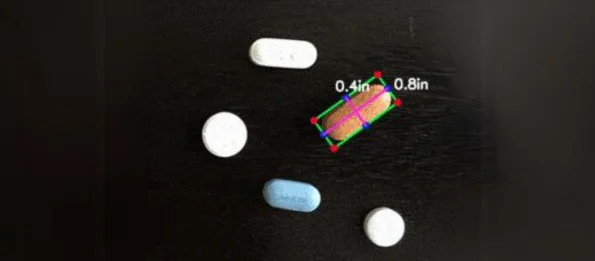

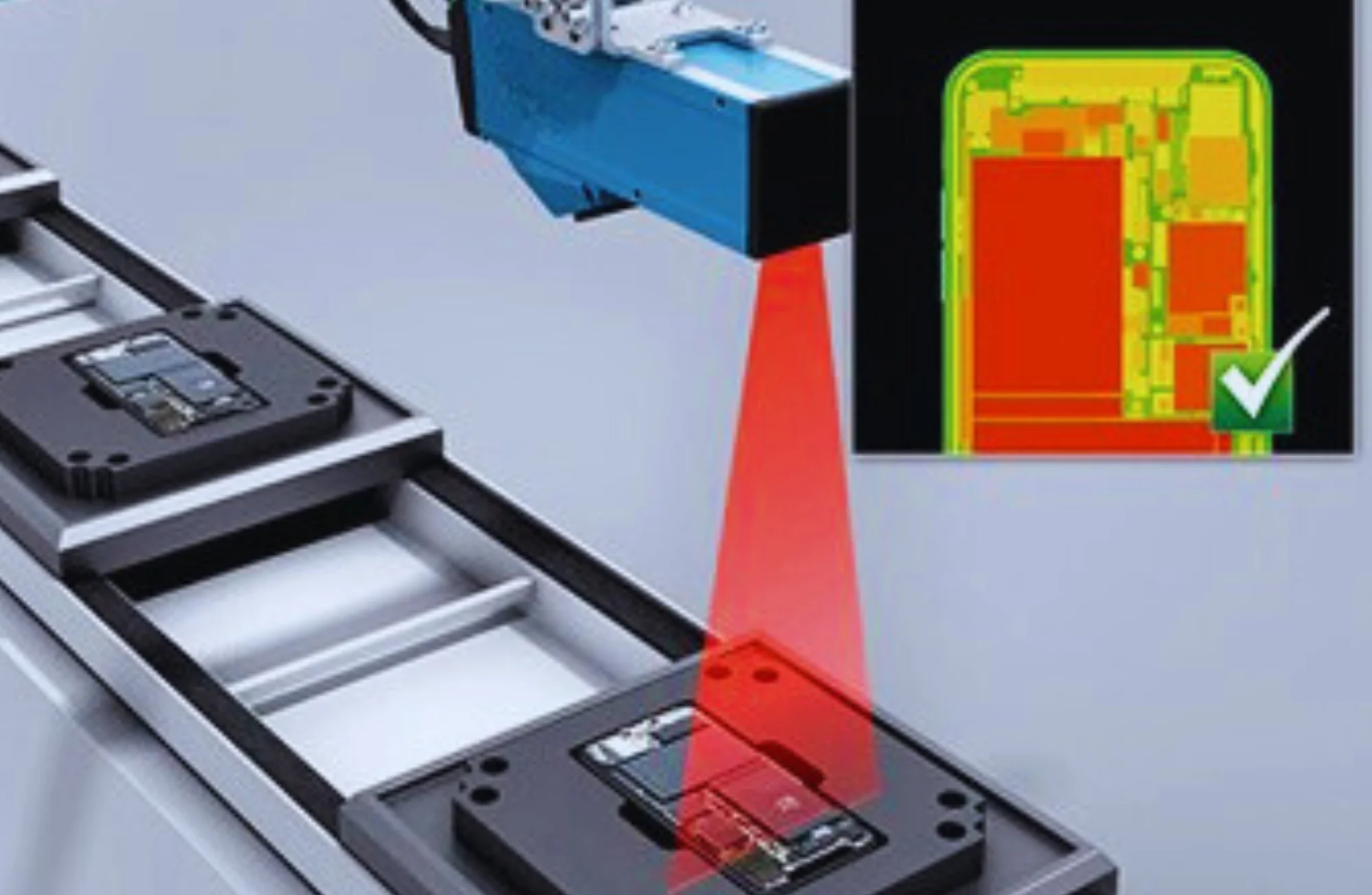

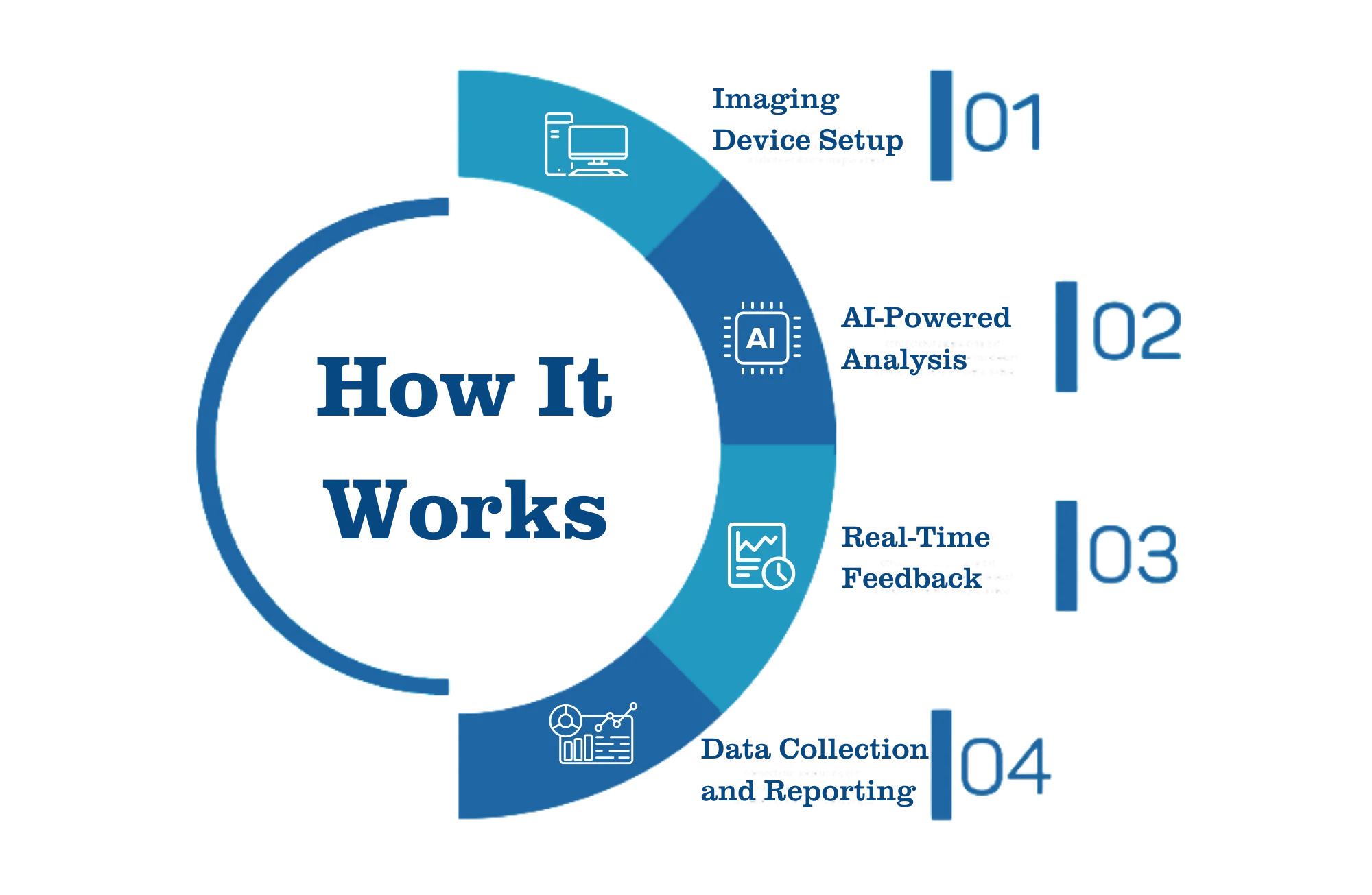

Our system uses high-resolution cameras and advanced AI algorithms to measure dimensions and diameters with micrometer accuracy. The non-contact nature ensures no interference with the product surface, making it ideal for delicate or fast-moving production lines.

The AI system inspects in real time, providing instant feedback to operators or automated systems. It can be integrated directly into the production line, allowing for immediate detection of size deviations and automatic corrections.

Our solution can be tailored for a wide range of industries and products, including cylindrical parts, shafts, pipes, and more. Whether measuring the outer diameter, inner diameter, or overall dimensions, the AI system adapts to specific needs.

Utilizing cutting-edge AI models and image processing techniques, the system processes multiple parts per second without compromising accuracy. This makes it suitable for high-volume manufacturing environments.

The system not only detects deviations but also generates detailed reports, tracking the dimensions of each inspected part. This data can be used for compliance, quality assurance, and continuous improvement efforts.

Automotive

Automotive Aerospace

Aerospace Medical Devices

Medical Devices Electronics

Electronics Metal Fabrication

Metal Fabrication Plastics and Rubber

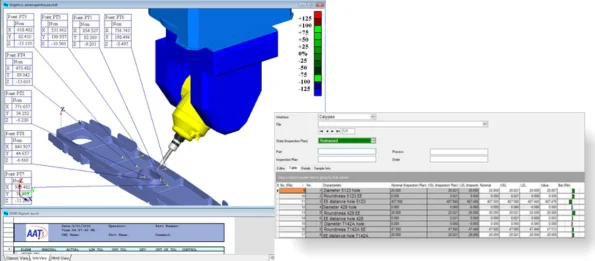

Plastics and RubberIntelgic’s machine vision AI system offers 3D Measurement capabilities for capturing and analyzing the complete geometry of complex parts in three dimensions. Using high-resolution cameras and structured light techniques, the system can create accurate 3D models of objects, enabling precise measurements of features such as depth, volume, angles, and surface contours. This is especially useful for inspecting intricate components in industries like aerospace, medical devices, and metal fabrication, where understanding the full 3D structure is critical. The 3D measurement data ensures the highest levels of quality control and supports detailed analysis for product development and manufacturing processes.

©2025 Intelgic Inc. All Rights Reserved.