AI driven Machine Vision System

Maintaining flawless quality in your electronics manufacturing is crucial. Even the smallest defect can lead to costly product failures. Intelgic's Machine Vision system, powered by AI, offers a powerful solution to identify and eliminate these defects, ensuring exceptional quality control throughout your production process.

Microscopic Defect Detection using AI

In electronics manufacturing, many components and circuits are so small that identifying defects with the naked eye is not feasible. Traditionally, microscopes have been employed to detect these minuscule imperfections. However, Intelgic’s vision system transforms this process by utilizing AI to enhance the resolution of images, magnifying tiny defects to visible levels without the need for cumbersome microscope setups. Our system employs advanced image processing algorithms to ensure thorough and accurate visual inspections.

Comprehensive Visual Inspection for Electronics

Intelgic’s Machine Vision System is equipped to identify a wide array of defects that are commonly or uncommonly encountered in electronics manufacturing. These include, but are not limited to:

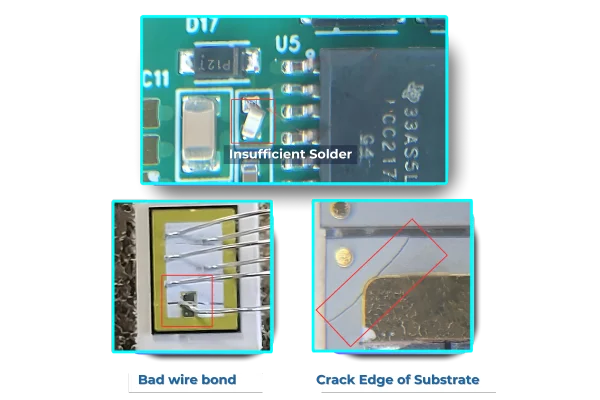

Missing Wire Bonds:

Detecting absence or misplacement of wire bonds that connect microchips to their packages.

Soldering Errors:

Identifying insufficient, excessive, or misplaced solder that can lead to poor electrical connections and circuit failure.

Cracked Edges on Substrates:

Spotting cracks or chips on the edges of substrates which can compromise the structural integrity of the circuit boards.

Bad Wire Bonds:

Recognizing poorly made wire bonds that could result in inadequate mechanical hold and electrical connectivity.

Missing Components:

Ensuring all necessary components are present and correctly placed on the PCB.

Component Misalignment:

Detecting improperly aligned components which could affect the functionality of the electronic device.

Unwanted Solder Bridges:

Identifying accidental solder connections between conductors that can cause short circuits.

Incorrect Components:

Wrong components installed, leading to malfunction.

Bent or Misaligned Components:

Physical damage to components that can affect functionality.

Lifted Leads:

Components not properly soldered to the PCB, causing connection issues.

Etching Defects:

Imperfections in the PCB copper traces due to faulty etching processes.

Scratches or Damage:

Physical damage to the PCB that can compromise electrical integrity.

Contamination:

Foreign material on the PCB that can lead to electrical shorts or malfunctions.

Why Intelgic's AI-powered Machine Vision system

A compelling alternative to the traditional machine vision system

- Cost-Effective: Traditional systems can range in price from $200,000 to upwards of $2 million, depending on complexity and functionality. Whereas, Intelgic's solution is 5X - 10X less than traditional systems.

- Exceptional Accuracy: Our state of the art AI algorithms will give a very high accuracy for all kinds of defect detection. We finetune AI algorithms based on your products and use cases until we achieve the desired accuracy level.

- High Scalability: Simply add cameras to your network as your production lines expand. Intelgic's AI seamlessly integrates the new data stream, eliminating the need for costly reconfiguration.

- Faster Implementation: Our out-of-the-box solution requires minimal setup, allowing you to be up and running quickly with minimal disruption to your production flow.

Get Started with Intelgic

Take your electronics manufacturing to the next level with Intelgic’s Machine Vision System. Reduce costs, enhance efficiency, and improve product quality through superior defect detection capabilities. Contact us today to learn how our system can integrate into your production line or to schedule a demonstration.

Embrace innovation in electronics manufacturing with Intelgic’s Machine Vision System, where cutting-edge technology meets practical, scalable solutions for unmatched quality control.

©2025 Intelgic Inc. All Rights Reserved.