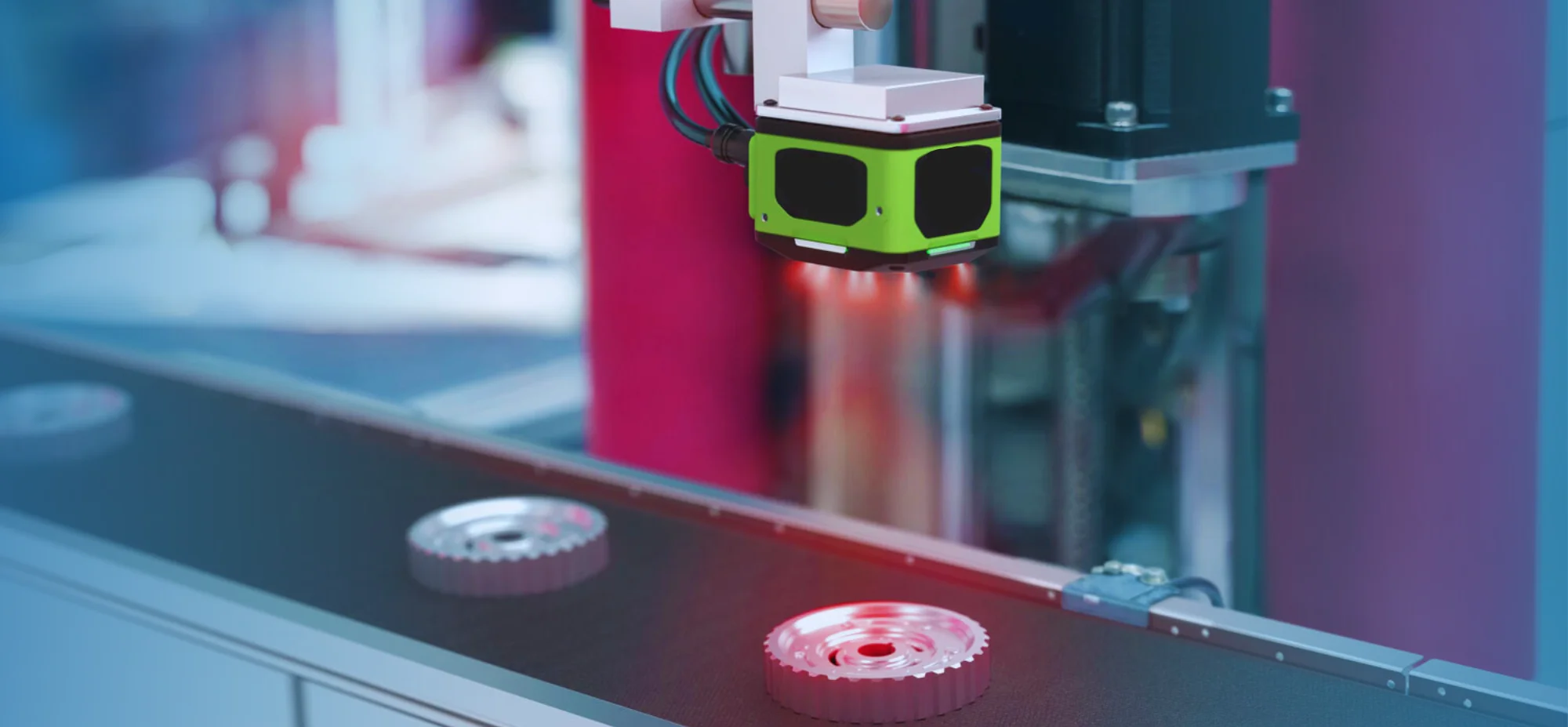

At Intelgic, we offer advanced surface defect detection solutions using cutting-edge CIS imaging systems and other machine vision cameras. Our solutions are customized to meet the specific needs of various industries, ensuring precise and reliable defect detection across a wide range of surfaces. Whether it’s plastic film, metal, glass, ceramic, or textiles, we’ve got you covered.

Intelgic’s surface defect detection systems are capable of identifying defects of various sizes, ensuring high precision and quality control.

Our high-resolution imaging systems can detect even the tiniest imperfections.

We customize our imaging systems to cover small and large fields of view (FOV) based on your requirements.

We can detect defects from 25 mm to less than 0.01 mm, offering precise inspection for all sizes.

At Intelgic, we don’t believe in a one-size-fits-all approach. We customize our camera systems—be it CIS imaging systems or regular machine vision cameras—based on your specific requirements, ensuring that our solutions deliver optimal performance for your unique needs. Whether you need small or large fields of view, our system covers defects from 0.01 mm upwards.

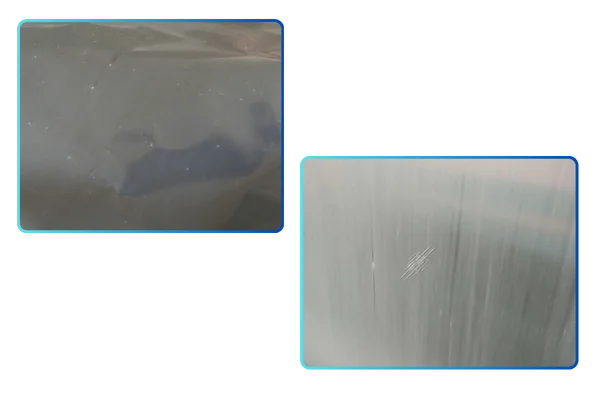

Plastic Film, Sheets, and Battery Foil Inspection

Our system inspects defects during the coating, slitting, and lamination processes, including:

Mismatch, bubbling, coating voids, wrinkles, dimension measurement.

Notching, lamination, tab surface inspection, and particle detection.

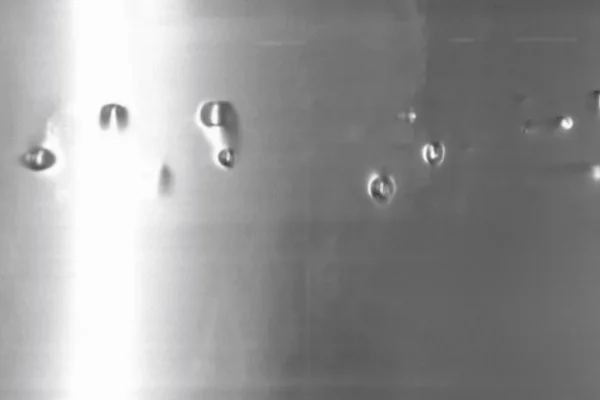

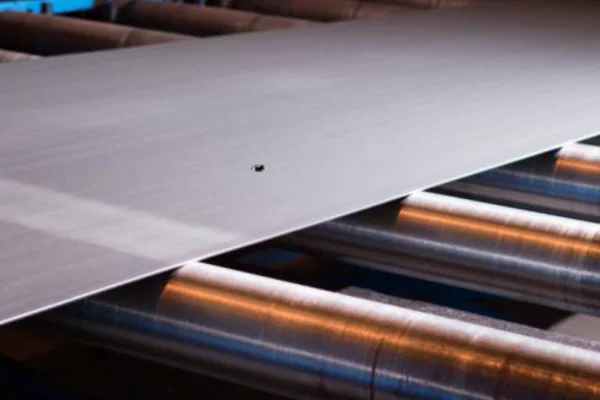

Our metal surface inspection solutions are designed to ensure top-tier quality control for steel, aluminum, and other metal surfaces during and after manufacturing.

Intelgic’s advanced machine vision system inspects various types of glass to ensure a flawless surface, detecting even the smallest defects in real-time.

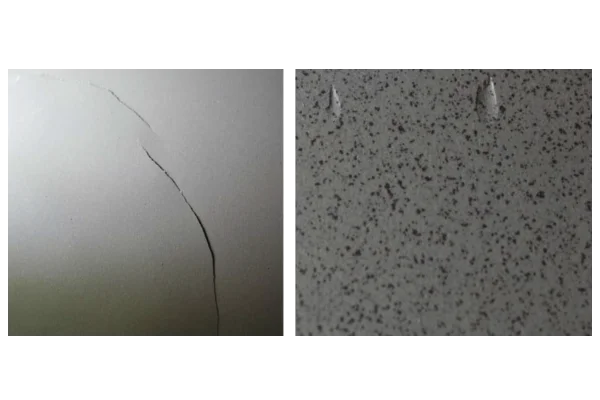

Our vision system ensures ceramic tiles and products meet stringent quality standards, detecting even the smallest surface flaws.

Our vision systems provide reliable defect detection for both wood and metal panels, ensuring they are free from surface imperfections.

Intelgic’s defect detection system ensures the highest quality in leather and textile products, identifying even the most subtle imperfections.

Our vision system accurately detects defects during the coating and lamination processes, ensuring high-quality output for foil paper and laminated materials.

Our vision system accurately detects defects during the coating and lamination processes, ensuring high-quality output for foil paper and laminated materials

We specialize in building customized machine vision systems to inspect large sheets used in various industries. Our advanced technology ensures even the smallest defects are identified.

For industries such as automotive manufacturing, our system is capable of inspecting large parts, ensuring defect-free components before assem

Intelgic’s vision system inspects ready parts to ensure defect-free components before they move to assembly or shipping.

©2025 Intelgic Inc. All Rights Reserved.