How to detect defects on Glass or similar product surfaces

Published on: Oct 16, 2024

Written by: Soumen das

How to Detect Defects on Glass and Similar Products Using CIS Imaging Systems

Glass and glass-like materials are widely used across multiple industries, from construction and automotive to consumer electronics and packaging. However, due to their transparency, reflectivity, and delicate surface structure, detecting defects on glass can be challenging. Defects such as scratches, cracks, inclusions, bubbles, and coating irregularities can compromise the quality and integrity of the final product, leading to customer dissatisfaction, safety concerns, and financial losses.

For these reasons, the inspection of glass products requires highly specialized techniques and technologies that can identify even the smallest imperfections. One of the most effective and versatile methods for detecting defects on glass is using Contact Image Sensor (CIS) imaging systems. CIS systems provide high-resolution imaging capabilities with the flexibility to customize resolution, pixel size, and working distance to match specific inspection requirements.

This article will explore the use of CIS imaging systems for detecting defects in glass and similar materials, covering the advantages of this technology, the importance of proper lighting, and the customizable features that make CIS systems suitable for a wide range of glass inspection applications.

Why Defect Detection on Glass is Challenging

Glass and glass-like materials present several challenges for defect detection:

- Transparency: The transparent nature of glass can make it difficult to detect defects such as scratches, chips, or inclusions, especially when the defect does not alter the refractive properties of the material significantly.

- Reflectivity: Glass surfaces can be highly reflective, causing glare and reflections that obscure defects during inspection. This makes lighting and sensor alignment critical.

- Surface Sensitivity: Glass surfaces are prone to scratches, smudges, and other surface-level defects, which can be difficult to detect without high-resolution imaging.

- Thin and Brittle: The thin, brittle structure of glass can result in microscopic cracks that are challenging to identify but can lead to breakage if undetected.

To overcome these challenges, manufacturers must use advanced imaging technologies that can capture highly detailed images, even on transparent or reflective surfaces.

.png)

CIS Imaging Systems: A Powerful Solution for Glass Defect Detection

Contact Image Sensor (CIS) technology is an ideal solution for inspecting glass and glass-like materials. CIS imaging systems are designed to scan surfaces with exceptional resolution and accuracy, making them well-suited for detecting even the smallest defects on transparent and reflective surfaces.

How CIS Imaging Works

CIS systems use a linear array of image sensors to capture images line by line as the glass or material moves beneath the sensor. These systems are typically mounted at a close working distance (typically between 15 mm and 30 mm), allowing them to capture detailed images of the glass surface with minimal distortion. CIS systems offer several advantages for inspecting glass materials:

- High Resolution: CIS imaging systems are capable of achieving very high resolution, down to micron levels, allowing them to detect tiny defects such as scratches, cracks, and surface irregularities.

- Close Working Distance: The close working distance of CIS systems allows for precise inspection with minimal optical distortion, which is especially important for flat, transparent materials like glass.

- Customizable Width: CIS systems can be customized based on the width of the material being inspected, providing full flexibility to accommodate different product sizes. This makes them ideal for inspecting large glass sheets, panels, or substrates.

- Flexible Pixel Size and Resolution: The resolution and pixel size can be selected based on the size of the defects that need to be detected. For example, if the minimum defect size is very small, a higher resolution with smaller pixel size can be chosen to capture finer details.

Key Advantages of CIS Imaging for Glass Inspection

- High-Speed Scanning: CIS systems are capable of high-speed scanning, making them suitable for real-time, inline inspection in fast-paced production environments.

- No Distortion: The close proximity between the sensor and the glass surface minimizes optical distortion, ensuring that the captured images accurately reflect the condition of the glass.

- Customization: CIS systems can be customized in terms of width, resolution, pixel size, and sensor configuration, providing manufacturers with a flexible solution for different types of glass products.

The Role of Lighting in Glass Inspection

Lighting is one of the most important factors when inspecting glass materials using CIS imaging systems. Proper lighting ensures that defects on the glass surface are highlighted and can be accurately detected by the imaging system. Since glass is transparent and reflective, the angle, intensity, and type of lighting used can significantly affect the quality of the inspection.

1. Lighting Angle

The angle at which light is projected onto the glass surface is critical for creating the necessary contrast between defects and the surrounding material. For example:

- Low-Angle Lighting: Low-angle lighting is effective for detecting surface-level defects such as scratches and cracks. This type of lighting casts shadows on surface irregularities, making them more visible to the imaging system.

- Direct Lighting: Direct lighting can be used to inspect internal defects such as bubbles, inclusions, and voids within the glass material.

- Diffuse Lighting: Diffuse lighting provides uniform illumination without casting harsh shadows or causing glare. This is ideal for inspecting glass surfaces where reflections could otherwise obscure defects.

2. Lighting Intensity and Contrast

The intensity of the lighting must be adjusted to create sufficient contrast between the defect and the glass material. Higher contrast makes it easier for the imaging system to detect small imperfections.

3. Backlighting

Backlighting is particularly useful for inspecting transparent materials like glass. By placing the light source behind the glass and using the CIS system to capture the silhouette of the defects, backlighting makes it easier to detect internal defects, such as inclusions, cracks, or air bubbles, within the glass.

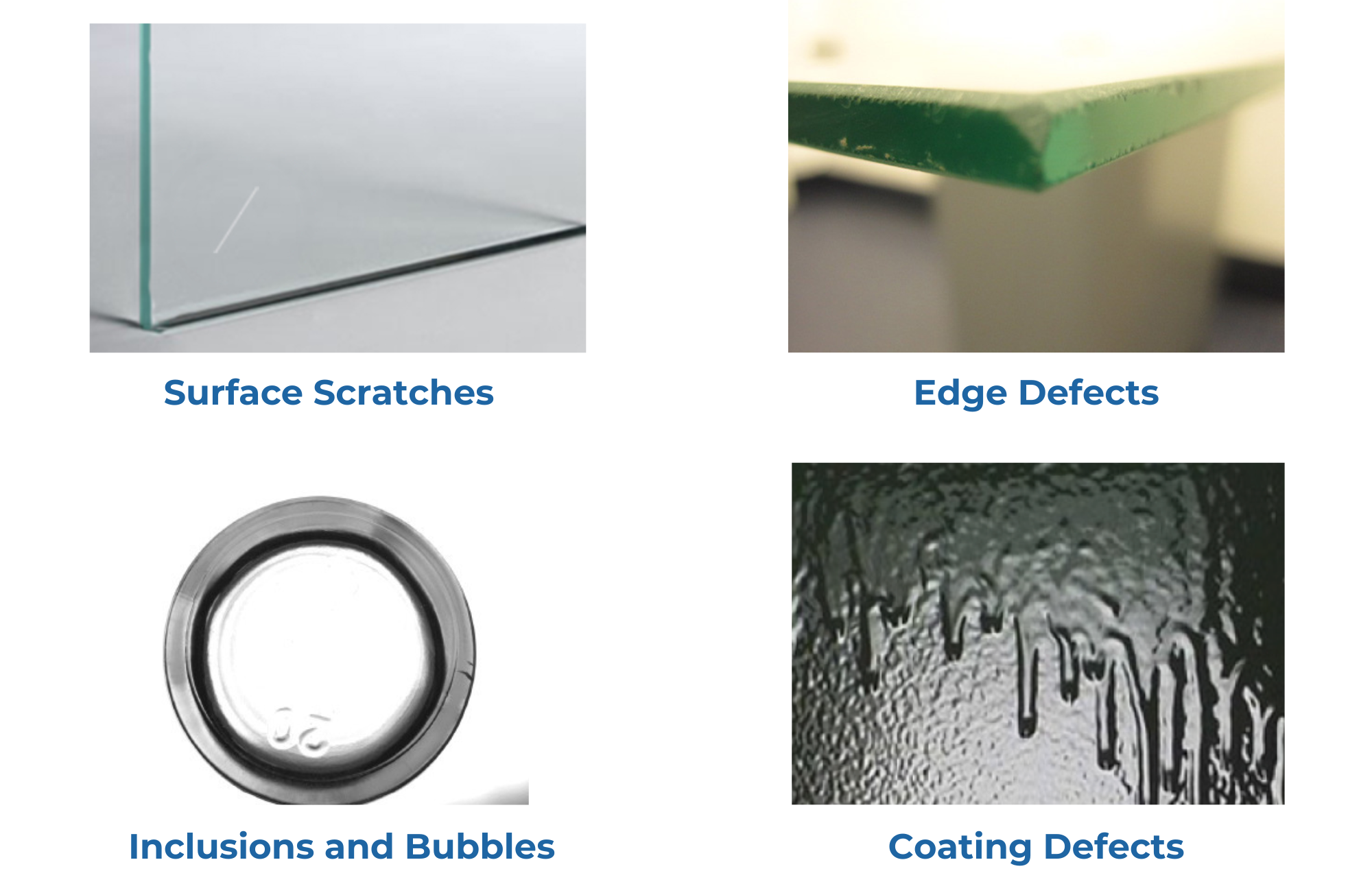

Types of Defects Detected on Glass and Similar Materials

The use of CIS imaging systems, combined with proper lighting, enables the detection of a wide variety of defects on glass and similar materials. Some common defects include:

1. Surface Scratches and Cracks

Scratches and cracks are some of the most common defects found on glass surfaces. These defects can occur during manufacturing, handling, or transportation. Even small scratches or micro-cracks can compromise the strength and safety of glass products.

- CIS Imaging Solution: CIS systems can capture high-resolution images of the surface, allowing for the detection of even the smallest surface-level scratches and cracks. Proper lighting ensures that these defects are highlighted clearly in the images.

2. Inclusions and Bubbles

Inclusions and bubbles are internal defects that occur during the glass manufacturing process. These imperfections can affect the optical properties and structural integrity of the glass.

- CIS Imaging Solution: With the use of backlighting, CIS systems can detect inclusions and bubbles by capturing the shadows or distortions caused by these internal defects.

3. Coating Defects

In some cases, glass may be coated with materials to enhance its properties (e.g., anti-reflective coatings or protective films). Defects in the coating, such as uneven application, peeling, or voids, can reduce the effectiveness of the coating.

- CIS Imaging Solution: CIS systems can be configured to detect coating defects by capturing variations in the surface reflectivity or texture. Proper lighting ensures that differences in the coating are visible.

4. Edge Defects

The edges of glass products are often subject to chipping, cracking, or other damage during cutting or handling. These defects can affect the overall structural integrity of the glass.

- CIS Imaging Solution: CIS systems can be positioned to inspect the edges of glass panels, detecting chips, cracks, or other irregularities that could lead to product failure.

Customizing CIS Imaging Systems for Specific Glass Inspection Needs

One of the key strengths of CIS imaging systems is their flexibility. These systems can be customized to meet the specific requirements of different glass inspection applications. The following features can be adjusted to optimize the system for detecting defects on glass:

1. Resolution and Pixel Size

The resolution and pixel size of the CIS system can be tailored to the size of the defects that need to be detected. For example, if the minimum defect size is 10 microns, the pixel size and resolution of the imaging system can be adjusted to ensure that defects of this size are captured with sufficient detail.

2. Width Customization

CIS systems can be customized to match the width of the glass material being inspected. Whether inspecting narrow glass strips or wide glass panels, the system can be configured to provide full coverage without missing any part of the surface.

3. Working Distance

The close working distance of CIS systems (typically between 15 mm and 30 mm) provides flexibility for different inspection setups. Depending on the space available and the size of the material, the working distance can be adjusted to optimize the quality of the captured images.

Detecting defects on glass and similar materials is a complex task that requires high-resolution imaging, precise lighting, and advanced image processing. CIS imaging systems provide an effective solution for inspecting glass surfaces, offering high-resolution, customizable imaging capabilities with a close working distance that minimizes distortion.

By integrating CIS imaging systems into glass inspection processes, manufacturers can detect surface and internal defects such as scratches, cracks, bubbles, and inclusions, ensuring the quality and reliability of their glass products. Proper lighting techniques, such as low-angle lighting or backlighting, enhance the visibility of defects, allowing for more accurate and efficient inspections.

With the ability to customize resolution, pixel size, and width, CIS imaging systems provide a flexible and powerful tool for inspecting glass products in industries ranging from automotive and electronics to construction and consumer goods.