Automotive Glass Inspection Automation

Clarity on every road. Precision inspection for windshields, sidelites, backlites, and more with Live Vision AI.

Book a call

Automotive glass must meet demanding optical and safety requirements while integrating various functional components.

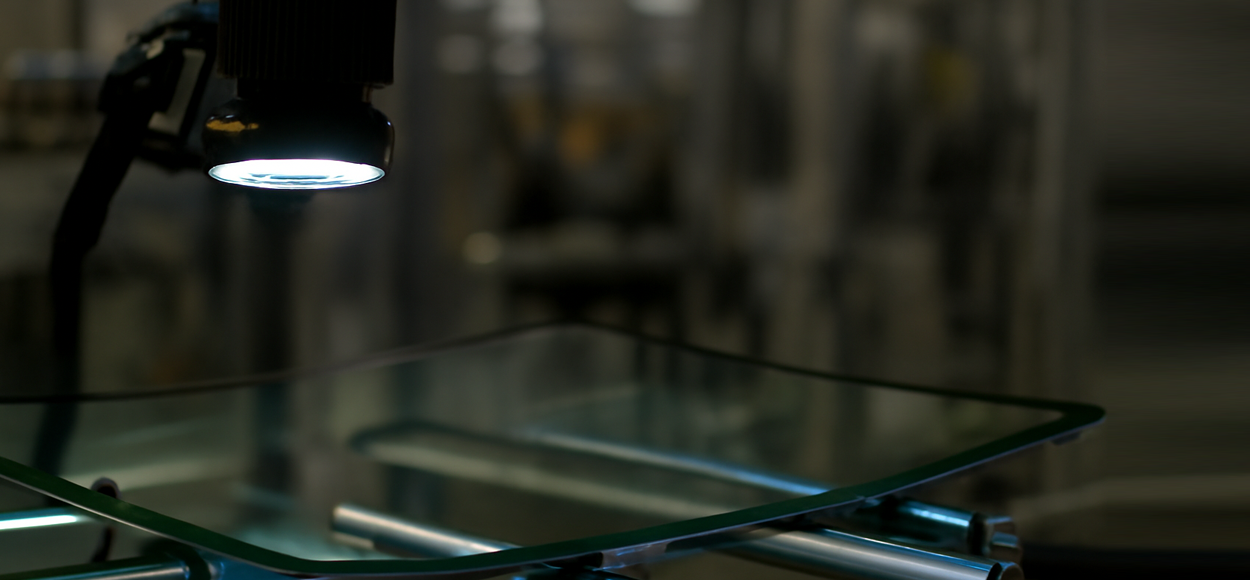

Our turnkey solution combines precision optics, application-specific lighting geometry, multi-axis motion, and Live Vision AI.

Low-angle oblique + controlled dark-field reveals hairline scratches without glare. Telecentric backlight creates crisp silhouettes for edge inspection.

Trained on automotive datasets to separate true defects from heater lines, prints, and structured reflections with high accuracy.

Tamper-evident digital record for every PASS panel with defect snapshots, measurement summaries, and full traceability.

Comprehensive defect detection across all critical areas of automotive glass.

Hairline scratches, sleeks, scuffs, digs/pits, stains, water spots, haze and rainbow artifacts on coated zones.

Ceramic frit pinholes, voids, smears, edge raggedness. Logo/mark presence, contrast, size, and position.

Perimeter chips, micro-cracks, shelling; bevel/chamfer quality. Hole/slot presence and size; VIN viewport sizing.

ADAS camera & sensor brackets position/orientation. Backlite defogger lines continuity. Encapsulation quality.

Outer contour vs. CAD overlay. Curvature/sag checks. Optional deflectometry for distortion/slope mapping in HUD region.

OCR/OCV of part numbers, E-marks, date/shift codes; barcode/2D code verification for complete traceability.

Precision-engineered components working in harmony for reliable inspection.

Precision-engineered for automotive glass inspection requirements.

Yes. AI models are trained on heater line patterns and use frequency/shape cues to avoid false positives; low‑angle dark‑field highlights true micro‑scratches.

Yes. We measure bracket pose vs. datums and check bead presence, width, and squeeze‑out. Orientation errors and missing/extra components are flagged.

Optionally, a deflectometry module maps slope/distortion and wedge proxies in the driver eye‑box and HUD region for process tuning and acceptance decisions.

With multi‑axis rails/gantry and soft‑nest or vacuum fixtures that stabilize the part while keeping optical surfaces safe.

Per‑panel DQC, shift/day reports, defect Pareto, and full audit logs with user actions; secure sharing for OEM/Tier‑1 stakeholders.

©2025 Intelgic Inc. All Rights Reserved.