Ensure Defect-Free Ceramic Plates with Fully Automated Inspection

Crack-free. Spotless. Reliable.

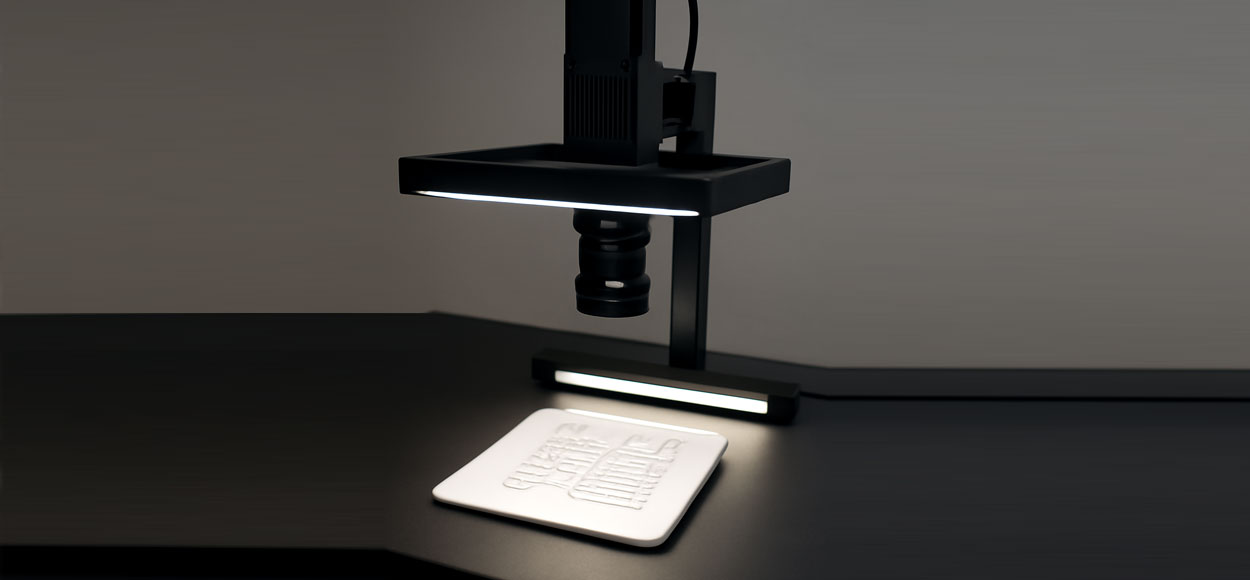

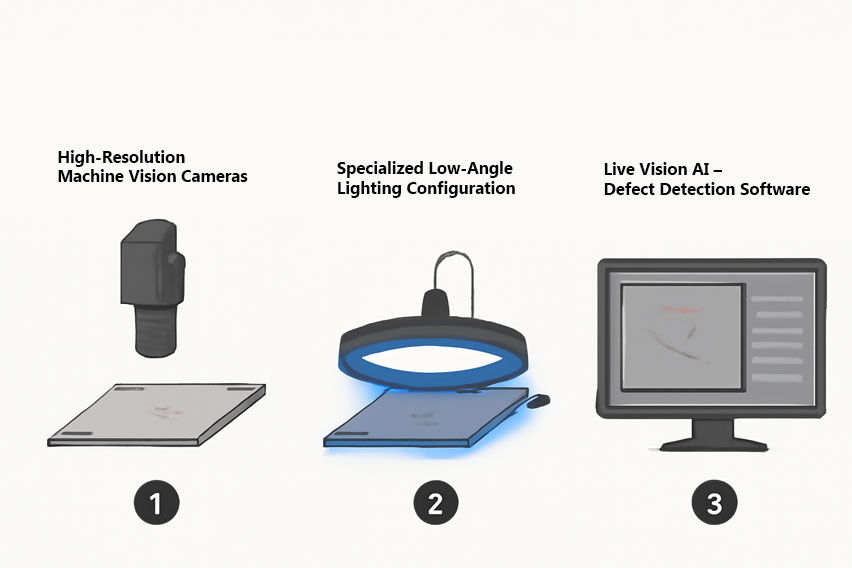

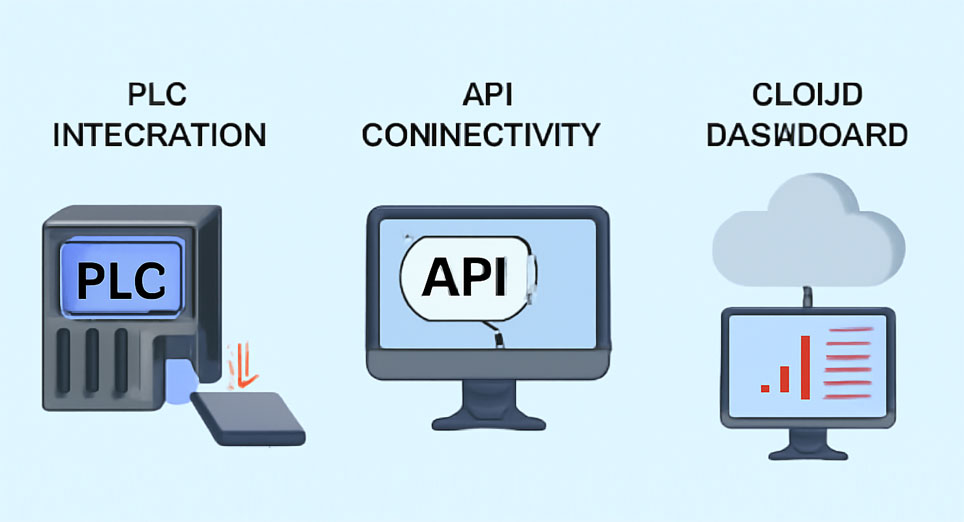

Automate the inspection of silica ceramic plates using Intelgic’s advanced machine vision system with smart lighting and high-resolution cameras. Designed for plates from 10 mm to 200 mm, our turnkey solution detects cracks, black spots, micro-waves, and more—so your production meets the highest quality standards.

Book a call