Automated Lens Inspection System for Precision Optical Quality

Precision Inspection for Precision Optics.

AI-powered quality inspection system tailored for transparent and sensitive lenses.

Book a call

Intelgic is a pioneer in designing and developing the fully automated inspection system for lenses.

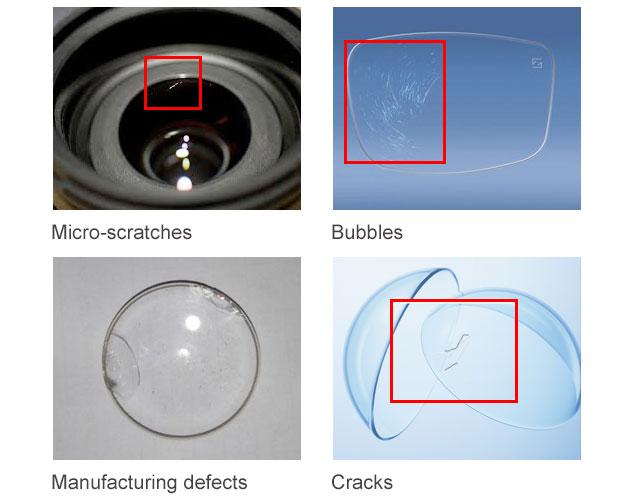

Lenses are critical components in medical devices, eyewear, diagnostic equipment, imaging tools, and scientific instruments. Given their transparent nature, curved surfaces, and extreme sensitivity to scratches or minute visual defects, inspecting lenses requires a highly specialized system. Intelgic provides an advanced AI-based lens inspection system designed to detect even the smallest imperfections on a wide range of transparent lenses—ensuring consistent optical quality, regulatory compliance, and reduced rework or rejection costs.

Transparent lenses present unique inspection difficulties that conventional systems struggle with

Reflection and refraction distort conventional imaging

Complex shapes complicate focus and lighting

Scratches or bubbles invisible to human inspectors

Multiple geometries require adaptable systems

Our system detects defects that compromise optical quality and performance

Specialized solutions for transparent materials and complex geometries

Trained on thousands of defect samples to distinguish between acceptable marks and true defects with severity classification.

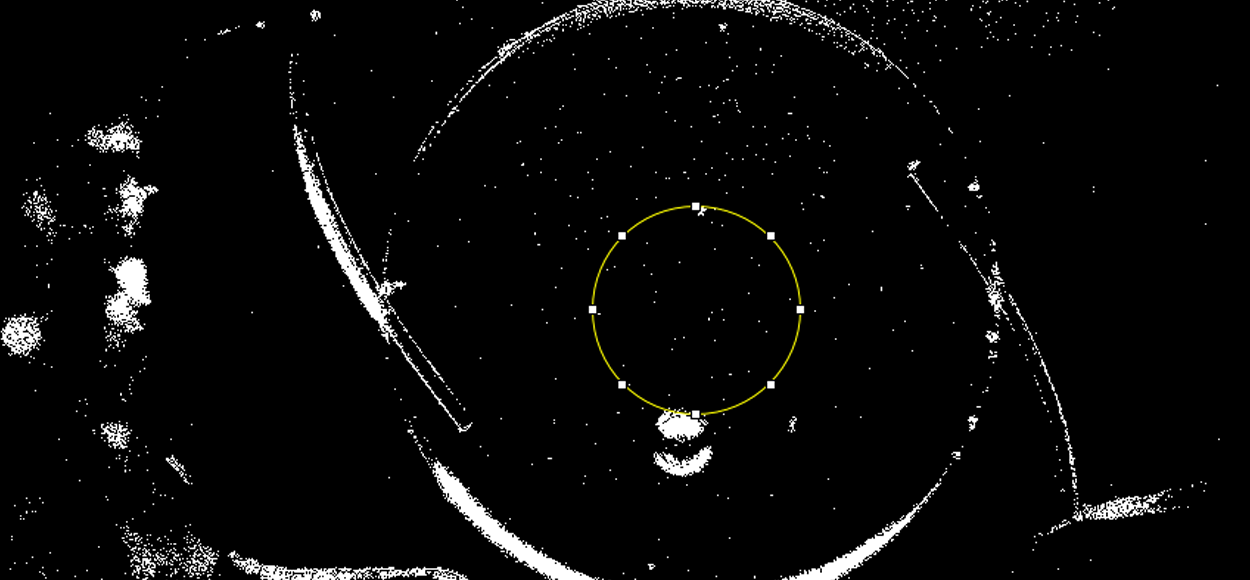

Backlighting, coaxial illumination, and dome lighting overcome optical challenges of transparent materials.

Real-time Pass/Fail decisioning with digital quality certificates and full traceability integration.

Adaptable for a wide range of precision optical applications

Medical-grade inspection for IOLs with micron-level precision

High-speed inspection for soft and rigid gas permeable lenses

Precision optics inspection for imaging applications

Critical defect detection for high-power laser applications

Expert solutions for your most challenging inspection requirements

Specialized in inspecting transparent and curved surfaces with proprietary techniques.

Tailored systems for any lens shape, size, and production requirements.

Meeting strict quality standards for medical devices and precision optics.

Intelgic designs and delivers custom lens inspection systems tailored to your device, production speed, and quality standards. From standalone units to fully integrated inline inspection stations, we provide end-to-end solutions that ensure every lens leaving your facility is flawless and compliant.

Contact us today to schedule a demo or request a proposal.

©2025 Intelgic Inc. All Rights Reserved.