Aircraft Window & Windshield Inspection Automation

See safety, not just defects. Intelgic automates visual and dimensional inspection of aircraft transparencies with Live Vision AI.

Book a call

Aircraft windows are transparent, curved, multi-layered, and highly polished, introducing inspection issues that standard systems miss.

Defects can vanish without the right illumination path and background control.

Specular surfaces & AR/conductive coatings mask sleeks, pits, and stains.

Thickness gradients cause refraction and double imaging, shifting apparent defect positions.

Hide sub-surface flaws (bubbles/seeds, delamination) unless lighting is carefully controlled.

Conductive films add patterns that can be mis-classified as defects.

Fastener zones & sealant boundaries are hard to illuminate and easy to miss.

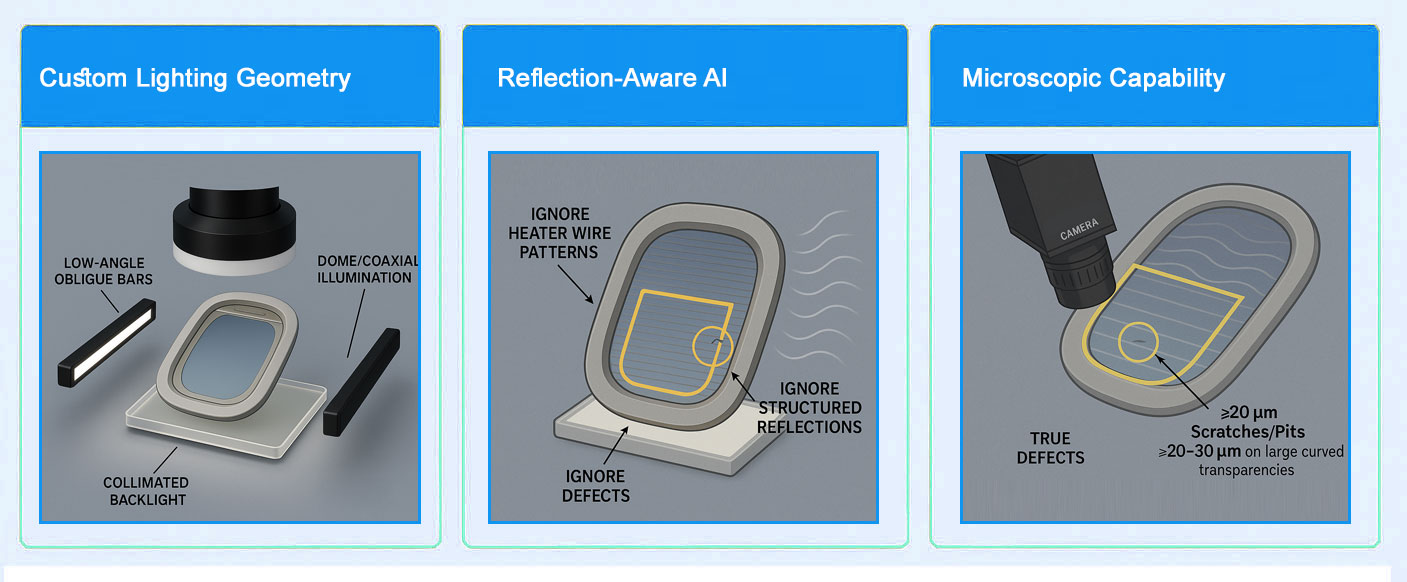

Our solution combines precision optics, application-specific lighting geometry, multi-axis motion, and Live Vision AI to detect micro-defects and validate geometry.

Matched to part size, shape, and layer stack with low-angle oblique bars, collimated backlight, and dome/coaxial illumination.

Trained on aerospace datasets to ignore heater wire patterns and structured reflections while detecting true defects.

Detects <10 µm scratches/pits on flats and ≈20–30 µm on large curved transparencies.

Comprehensive defect detection across all critical areas of aircraft transparencies.

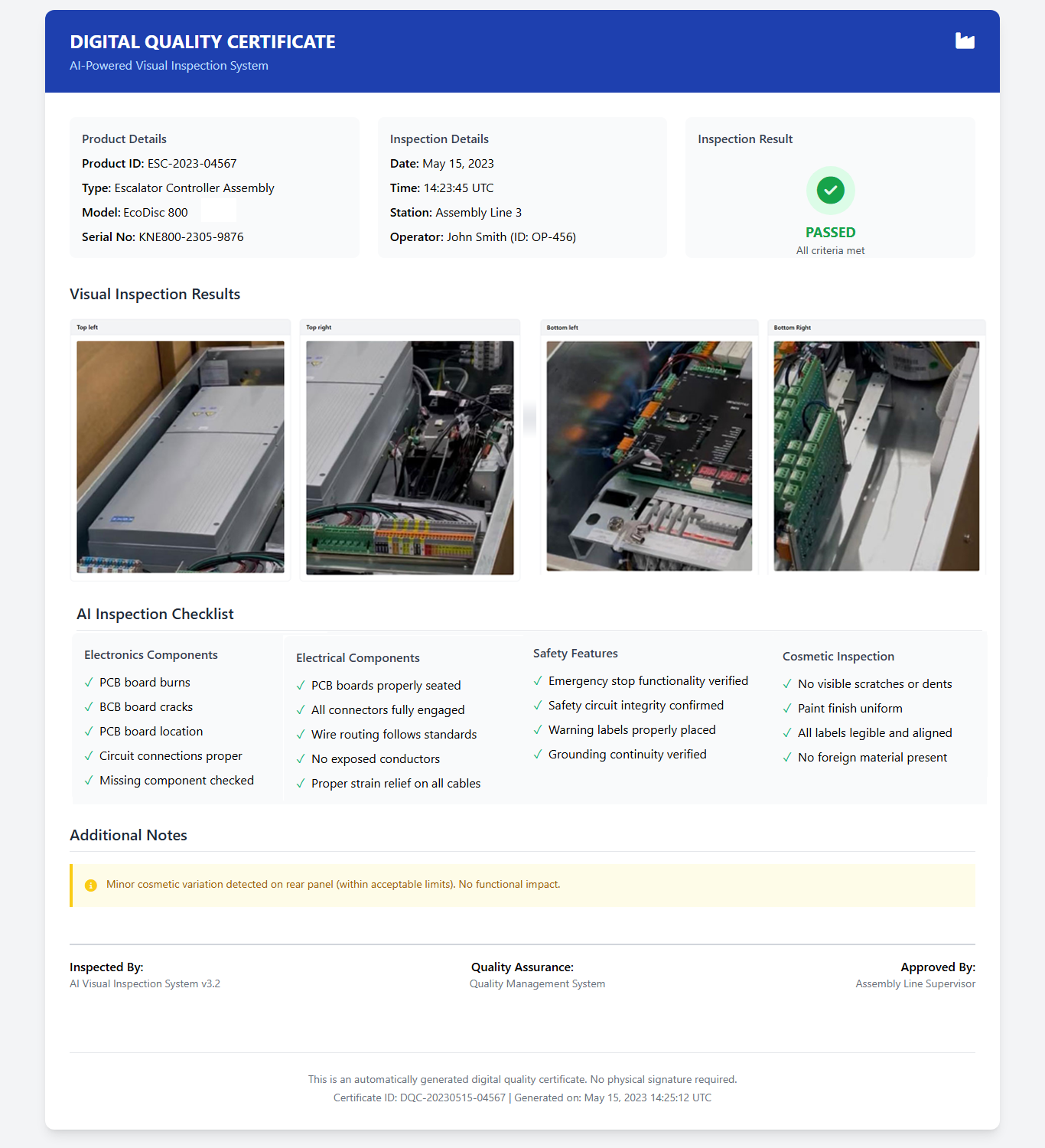

For every PASS transparency, Intelgic issues a digital, shareable, tamper-evident record of inspection results.

Yes. The AI is trained on heater wire geometries and uses frequency/shape cues to prevent false positives; low‑angle dark‑field isolates true micro‑scratches.

Multi‑angle and dual‑side illumination accentuate interlayer anomalies such as bubbles, seeds, and early delamination for targeted review.

Optionally, a deflectometry module produces reflection‑based slope/cosmetic maps to support process tuning and acceptance decisions.

With multi‑axis rails/gantry and soft‑nest or vacuum fixtures that stabilize the part while keeping optical surfaces safe.

Per‑part DQC, shift/day reports, defect Pareto, and full audit logs with user actions; secure sharing for OEM/MRO stakeholders.

©2025 Intelgic Inc. All Rights Reserved.