Translucent Plastic Inspection Automation

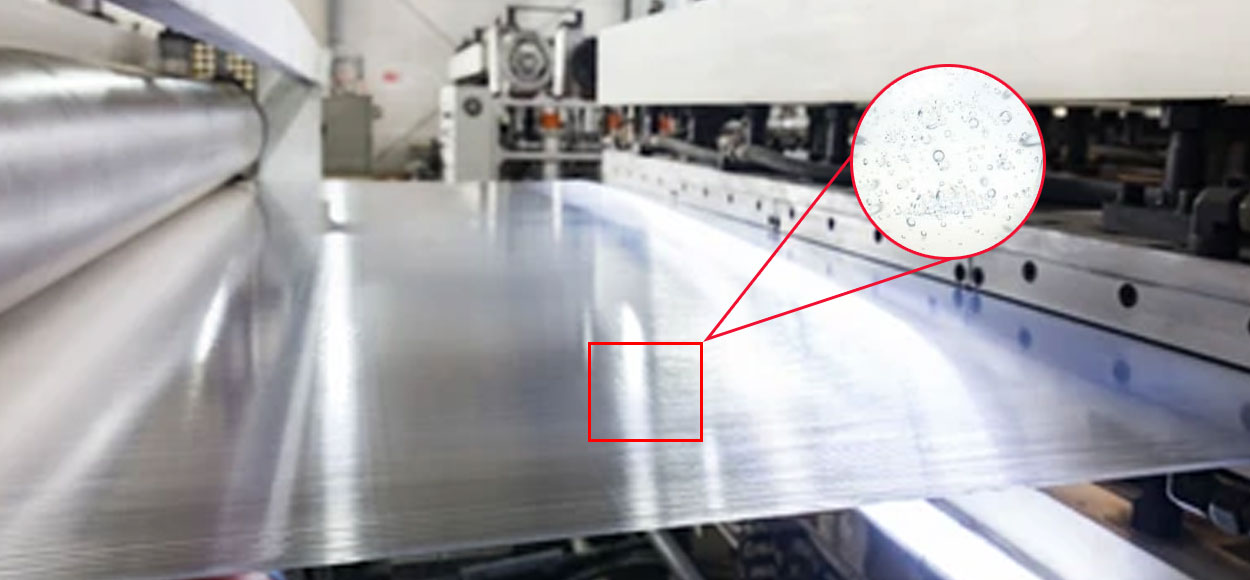

See through the scatter with our advanced vision systems designed for translucent and semi-transparent materials

Book a call

Our systems are optimized for a wide range of translucent and semi-transparent plastics across industries

Translucent parts transmit light but scatter it internally, creating unique inspection challenges

Defects blend with milky background, making detection difficult

Bubbles, gels, and contaminants don't register in standard bright-field

Altered brightness causes false calls in traditional systems

Gloss vs. matte zones from molding create inconsistent readings

Transmission/backlight converts internal structure into measurable contrast

Manages surface glare and visualizes stress in transparent materials

Optional UV/NIR enhances contrast on specific resins and additives

Adaptive background models with thickness-aware false-positive control

With the right optics, Intelgic detects surface scratches <10 µm and internal inclusions ≈20–50 µm (material-dependent), far beyond human inspection capabilities.

Comprehensive inspection capabilities across material, surface, geometry, and functional aspects

Our solutions serve critical quality control needs across multiple industries

Precision-engineered components working in harmony for reliable inspection

Typical system capabilities across different applications

Detection of surface sleeks and micro-scratches

Bubbles, gels, and foreign particles (material-dependent)

Up to 90 parts/min on rotary cells for small/medium parts

Actual performance depends on material, thickness, optics, and your acceptance criteria. Intelgic tunes lighting, optics, motion, and AI to your specific targets.

Yes. We use calibrated transmission and AI models that compensate for expected thickness gradients, reducing false calls.

Yes. Transmission lighting (diffuse or collimated) reveals sub‑surface inclusions. Spectral tuning can further improve contrast on some resins.

We combine transmission for internals with polarized/coaxial or dark‑field for surface cosmetics, then fuse results.

Yes. We provide stimulus‑controlled tests to map hot‑spots and uniformity under specified LED conditions.

Yes. Line‑scan transmission supports continuous inspection up to 80 m/min, with pinhole and inclusion detection.

©2025 Intelgic Inc. All Rights Reserved.