When and Why to Use CIS Cameras

Published on: Nov 26, 2024

Written by: Soumen das

Image Sensor (CIS) camera module

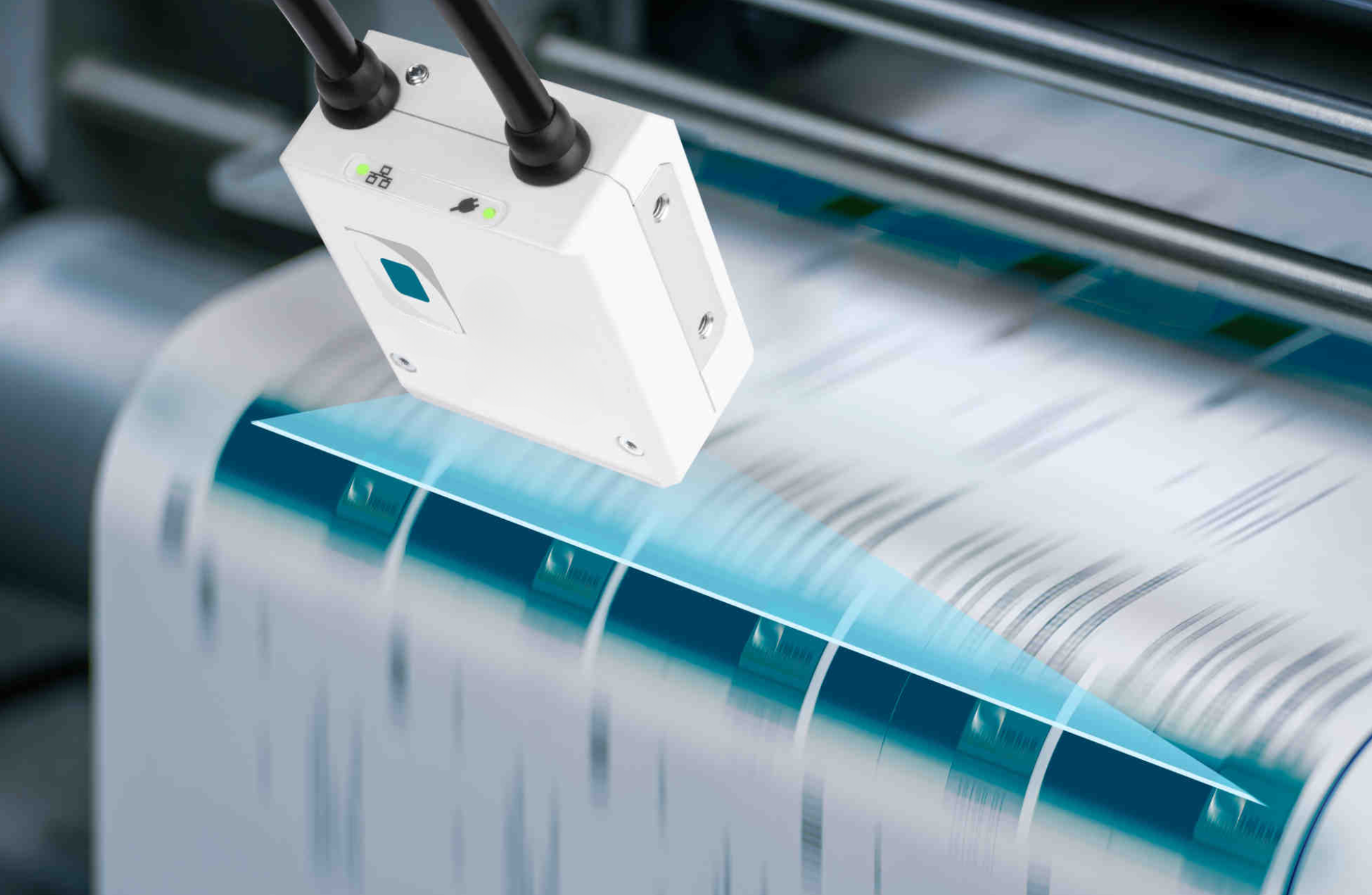

In high-speed manufacturing environments, inspecting continuous sheets of materials for defects is a challenging task. Ensuring precise and reliable inspection requires choosing the right imaging solution, and one of the most advanced tools for such applications is the Contact Image Sensor (CIS) camera module. CIS cameras excel in scenarios involving fast-moving, wide sheets where traditional imaging solutions face limitations.

This article explores when to use CIS cameras, how they work, and their advantages and limitations compared to other imaging technologies like line scan cameras.

camera module.png)

Understanding the Basics of Line Scan Cameras

Before diving into CIS cameras, it’s essential to understand the prevalent line scan camera technology:

-

What is a Line Scan Camera?

A line scan camera captures images line by line and stitches them together to form a 2D image. It is widely used in applications where materials are continuously moving on a fast conveyor belt. -

Applications of Line Scan Cameras:

Line scan cameras are ideal for inspecting continuous sheets such as textiles, films, or metal surfaces, especially when precision and speed are critical.

Examples:-

Film inspection

-

Textile defect detection

-

Metal sheet quality control

-

-

Limitations of Line Scan Cameras:

-

Working Distance: If the defect size is very small (e.g., less than 1 mm or at the micron level), the camera needs to be positioned closer to the sheet. This reduces the Field of View (FOV) and requires multiple cameras to cover the entire width of the sheet.

-

Complex Setup: Using multiple cameras for wide sheets increases system complexity and costs.

-

Why Use CIS Cameras?

Contact Image Sensor (CIS) cameras address many of the limitations of line scan cameras, offering a versatile solution for specific applications. Here's a detailed breakdown of why and when CIS cameras should be used:

Wide Sheet Inspection

-

When the width of the sheet is large, using multiple line scan cameras to cover the entire surface becomes complex and costly.

-

CIS Solution:

CIS cameras are customizable in length and can be tailored to match the width of the sheet. This eliminates the need for multiple cameras, simplifying the system setup.

Micron-Level Defect Detection

-

For detecting defects smaller than 1 mm or at the micron level, high-resolution sensors (such as 8k or 16k) are required.

-

CIS Solution:

A CIS module with a 16k image sensor can efficiently capture micron-level defects with unparalleled precision.

Close Proximity Imaging

-

CIS cameras operate at a very close working distance (15–35 mm). This proximity allows them to capture highly detailed images of the sheet, making them ideal for applications requiring extreme accuracy.

Vibration-Free Environments

-

CIS cameras are sensitive to vibrations due to their close proximity to the sheet. When vibration can be minimized, CIS cameras deliver exceptional results.

-

Best for: Smooth and stable conveyor systems.

Shiny and Reflective Surface Inspection

-

Traditional cameras struggle with reflective or shiny materials due to glare and uneven light distribution.

-

CIS Solution:

CIS modules excel at inspecting materials like:-

Foil paper

-

Aluminum-coated sheets

-

Films and smooth surfaces

-

Label scanning

-

Coating materials

-

Fast-Moving Lines

-

CIS modules can handle high-speed production lines effectively, making them a reliable choice for fast-moving materials such as films or continuous labels.

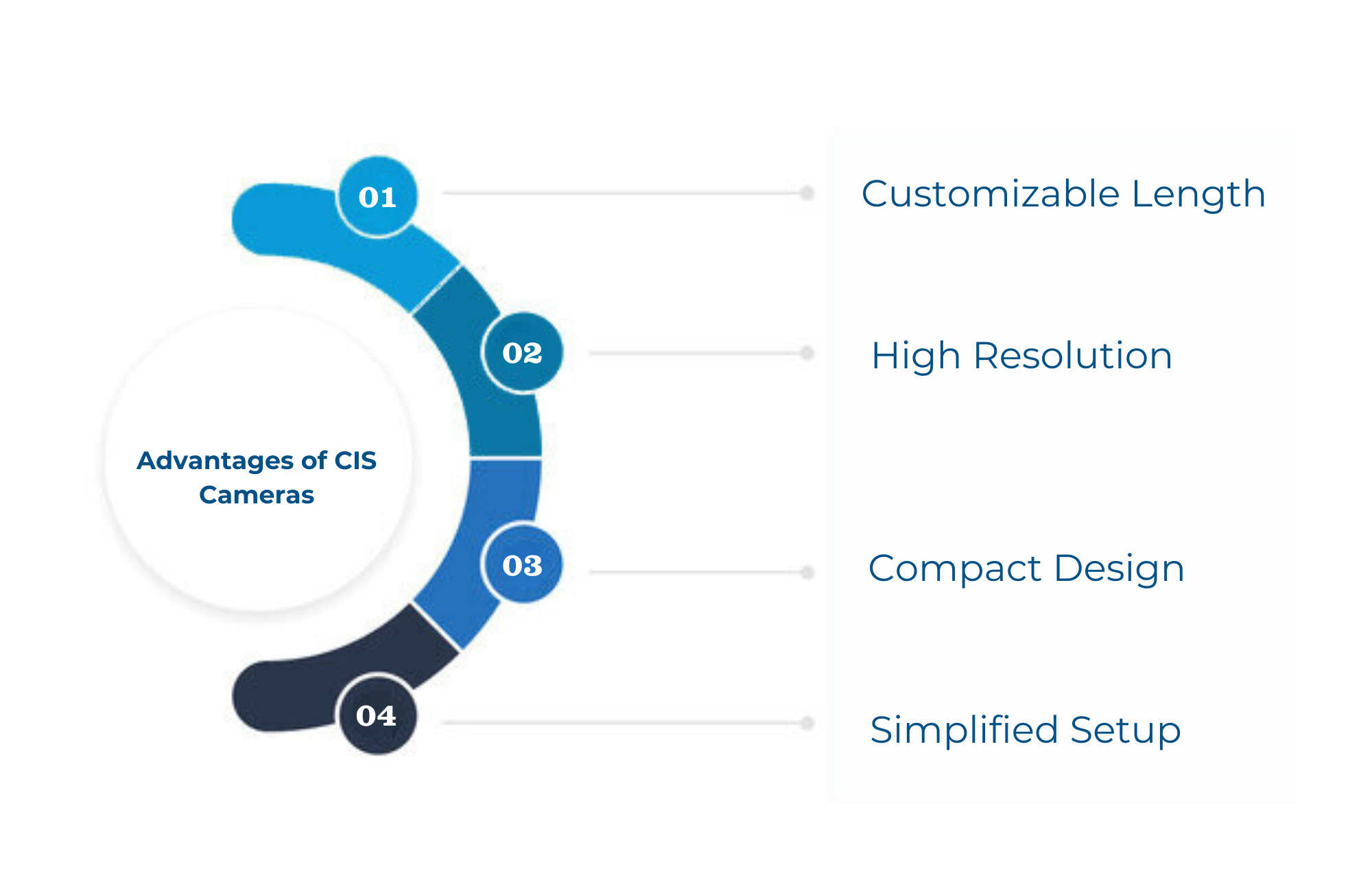

Advantages of CIS Cameras

-

Customizable Length:

CIS cameras are fully customizable, allowing manufacturers to match the camera length to the sheet width, eliminating the need for multiple cameras. -

High Resolution:

With sensors like 8k or 16k, CIS cameras capture intricate details and can detect micron-level defects. -

Compact Design:

CIS modules are compact and designed for close-proximity inspection, making them ideal for space-constrained setups. -

Simplified Setup:

Unlike line scan cameras requiring complex multi-camera systems for wide sheets, CIS cameras offer an all-in-one solution.

Limitations of CIS Cameras

-

Close Working Distance:

CIS cameras operate at a distance of 15–35 mm from the sheet. This can pose challenges if:-

The sheet vibrates significantly.

-

There are irregularities on the surface.

-

-

Not Suitable for Rough Surfaces:

CIS cameras are not ideal for inspecting rough or uneven surfaces. For such applications, other imaging solutions, such as line scan cameras or area scan cameras, may be more effective.

Applications of CIS Cameras

CIS cameras are most effective in specific use cases where their unique capabilities shine. Some key applications include:

-

Foil Inspection: Detecting scratches, dents, or irregular coatings on reflective surfaces like aluminum foil.

-

Film Quality Control: Identifying micron-level defects in thin films used in packaging or electronics.

-

Label Scanning: Ensuring the accuracy and quality of printed labels on continuous sheets.

-

Smooth Surface Inspection: Detecting imperfections in polished or glossy materials.

-

Coating Inspection: Evaluating uniformity and quality of coatings on metal sheets or other surfaces.

Choosing the Right Imaging Solution

Selecting the appropriate imaging technology depends on several factors, including:

-

Material Type:

-

Smooth and reflective materials → CIS Cameras

-

Rough or irregular surfaces → Line Scan Cameras

-

-

Defect Size:

-

Sub-millimeter or micron-level defects → High-resolution CIS or line scan cameras.

-

-

Width of the Sheet:

-

Wide sheets → CIS cameras for a single-camera solution.

-

Narrow sheets → Line scan cameras can suffice.

-

-

Line Speed:

-

High-speed production lines → Both CIS and line scan cameras, depending on application requirements.

-

-

Surface Vibration:

-

Stable surfaces → CIS Cameras.

-

Vibrating or uneven surfaces → Alternative imaging solutions.

-

CIS cameras provide a robust and efficient solution for inspecting continuous sheets in manufacturing processes, particularly for applications involving shiny, reflective, or smooth surfaces. Their ability to detect micron-level defects with customizable length and high resolution makes them a standout choice for complex inspection tasks. While they have limitations, such as sensitivity to vibrations and close working distances, their advantages in precision and simplicity make them indispensable for many industries.

By carefully evaluating factors like material type, defect size, sheet width, and line speed, manufacturers can choose the optimal imaging solution for their specific needs—whether it’s a CIS camera, line scan camera, or a combination of both.