What is Motion Blur?

Published on: Dec 05, 2024

Written by: Soumen das

What is Motion Blur ?

Motion blur is a phenomenon that occurs when a moving object is captured by a camera or imaging device, resulting in a blurred or smeared appearance of the object in the image. This effect happens when there is a mismatch between the movement of the object and the exposure time or frame capture rate of the imaging system. While motion blur can be an intentional artistic effect in photography or film, it is often undesirable in technical fields like machine vision or automated optical inspection (AOI), where clarity and precision are essential.

Understanding the Causes of Motion Blur

Motion blur is primarily caused by relative motion between the camera and the object being imaged during the exposure period. Here are the key factors that contribute to motion blur:

-

Object Movement Speed:

The faster the object moves during the exposure, the greater the likelihood of blur. For example, a fast-moving conveyor belt in a production line can cause motion blur if the imaging system is not configured correctly. -

Camera Exposure Time:

-

Long Exposure Time: If the camera’s exposure time is too long, the moving object appears smeared in the image as light from different positions is recorded over the same sensor area.

-

Short Exposure Time: A shorter exposure reduces motion blur but requires more light for proper image brightness.

-

-

Camera Frame Rate:

A low frame rate may miss critical details of a moving object, causing blur or gaps in the image. -

Relative Camera Motion:

If the camera itself moves during the exposure, it can introduce blur into the captured image, even if the object is stationary.

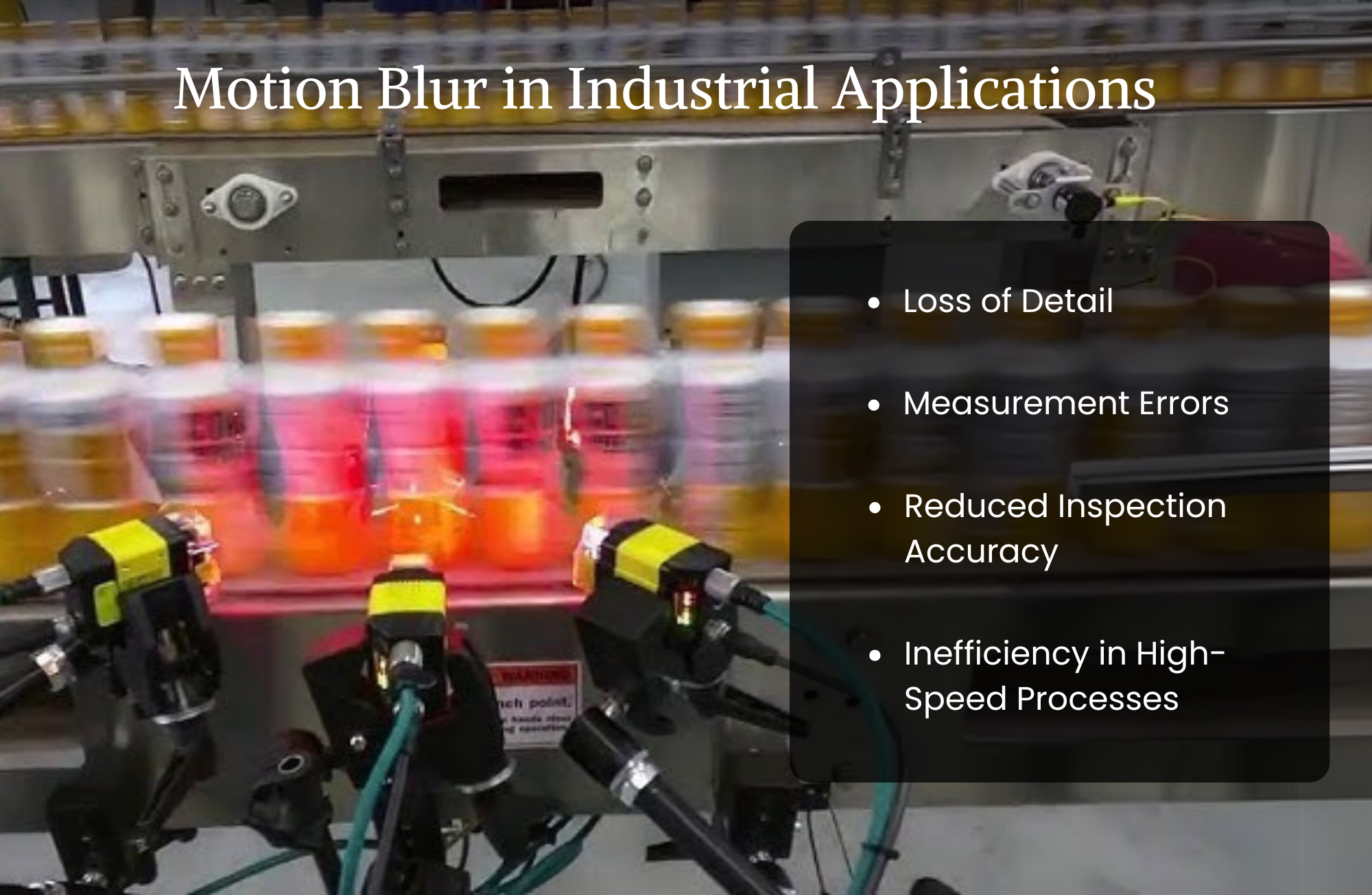

Motion Blur in Industrial Applications

Motion blur is particularly problematic in industrial and technical imaging applications, such as defect detection, automated inspection, or high-speed manufacturing. Here’s why:

-

Loss of Detail:

Motion blur obscures fine details, making it difficult to detect small defects like cracks, scratches, or dimensional inconsistencies. -

Measurement Errors:

In precision industries, blurred edges or features can lead to inaccurate measurements, compromising quality control. -

Reduced Inspection Accuracy:

Automated inspection systems rely on sharp, high-contrast images to identify anomalies. Motion blur can result in missed defects or false positives. -

Inefficiency in High-Speed Processes:

In fast-moving production lines, motion blur can make it challenging to inspect products efficiently and accurately.

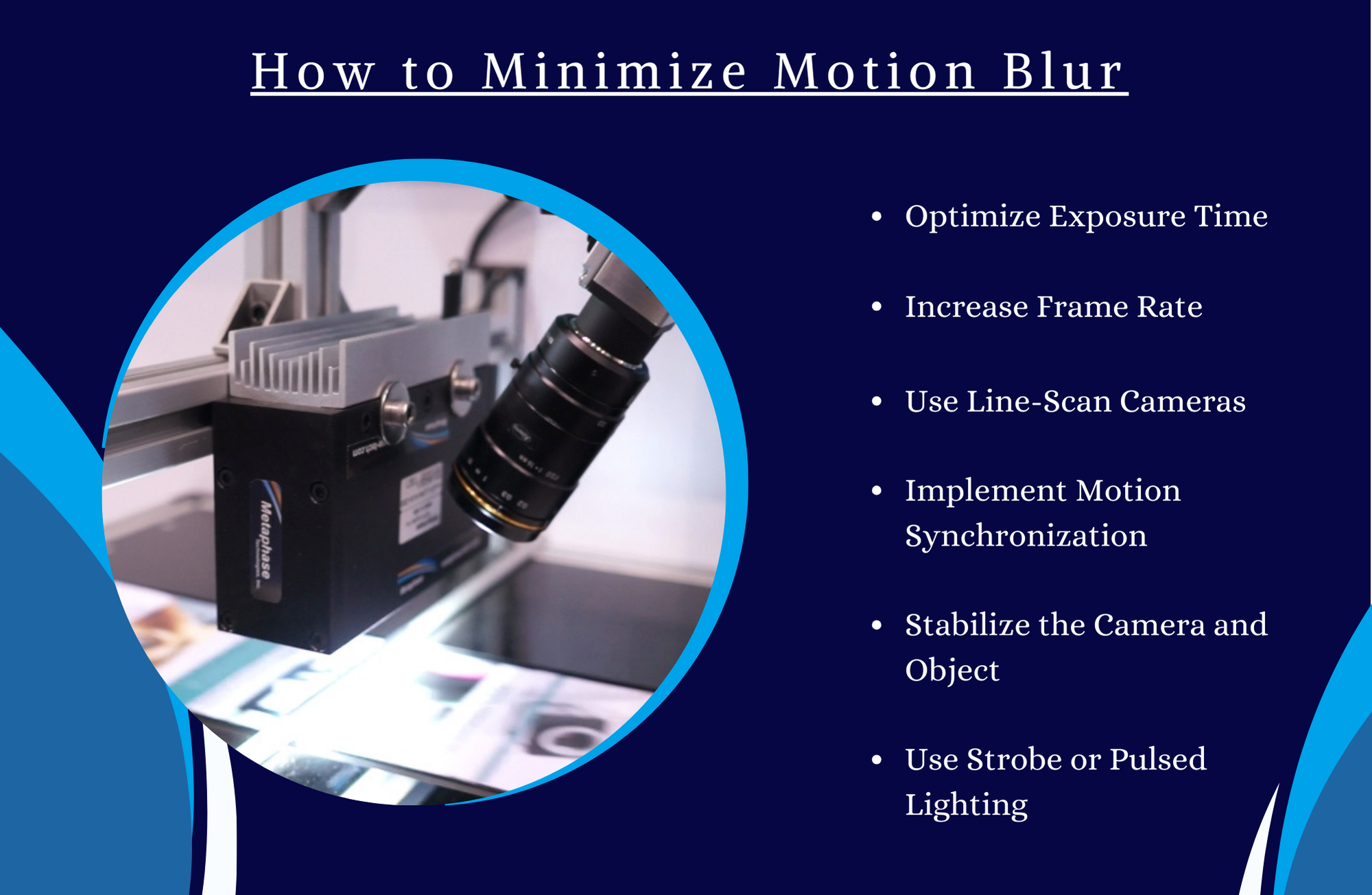

How to Minimize Motion Blur

Motion blur can be mitigated through careful system design and configuration. Here are some strategies:

-

Optimize Exposure Time:

-

Use shorter exposure times to reduce the impact of object motion.

-

Pair this with proper lighting to maintain image brightness despite reduced exposure.

-

-

Increase Frame Rate:

-

Use high-frame-rate cameras to capture more frames per second, reducing the relative motion recorded in each frame.

-

This is particularly useful in high-speed production lines.

-

-

Use Line-Scan Cameras:

-

For moving objects like conveyor belts, line-scan cameras capture images one line at a time, stitching them into a high-resolution image.

-

This approach is ideal for continuous inspection processes.

-

-

Implement Motion Synchronization:

-

Synchronize the camera’s capture rate with the object’s movement using encoders or triggers to ensure sharp images.

-

-

Stabilize the Camera and Object:

-

Ensure both the camera and the object remain stable during imaging to avoid introducing additional motion.

-

-

Use Strobe or Pulsed Lighting:

-

Pulsed lighting flashes for a very short duration, effectively “freezing” the motion of the object during the exposure, even at high speeds.

-

Intentional Motion Blur in Art and Photography

While motion blur is undesirable in technical and industrial contexts, it is often used deliberately in photography, videography, and visual arts to create a sense of movement and dynamism. For instance:

-

Panning Shots: Capture a moving subject sharply while blurring the background.

-

Long Exposure Photography: Create artistic effects like light trails or flowing water.

-

Cinematic Motion Blur: Adds realism to fast-moving scenes in movies or games.

The Science Behind Motion Blur: Shutter Speed and Motion

Motion blur can be explained using the relationship between shutter speed and object motion:

-

Shutter Speed (Exposure Time):

Shutter speed determines how long the camera sensor is exposed to light. The longer the exposure, the more motion is captured, leading to blur. -

Motion Path:

The distance traveled by the object during the exposure time determines the extent of blur. For example:-

If an object moves 1 mm during the exposure time, its image will appear smeared over that distance.

-

Reducing exposure time minimizes the motion path captured, resulting in a sharper image.

-

Motion Blur vs. Focus Blur

It’s important to distinguish motion blur from focus blur:

-

Motion Blur: Caused by the relative motion of the object or camera during exposure.

-

Focus Blur: Occurs when the object is outside the camera’s depth of field, resulting in an out-of-focus image.

While both degrade image quality, their solutions differ. Motion blur is addressed through faster exposure or synchronization, while focus blur requires proper lens and focus adjustments.

Motion blur is a critical consideration in both photography and industrial imaging. While it can be an artistic tool in creative fields, it poses significant challenges in machine vision and automated optical inspection. Minimizing motion blur requires optimizing camera settings, using specialized imaging devices like line-scan cameras, and employing advanced lighting techniques.

By addressing motion blur effectively, industries can ensure sharper images, better defect detection, and improved quality control, contributing to more efficient and reliable manufacturing processes. For tailored machine vision solutions, Intelgic offers expertise in designing and implementing systems that eliminate motion blur while meeting the unique needs of your production line.