Ceramic Surface Inspection Automation Using Machine Vision AI

Published on: Dec 02, 2024

Written by: Soumen das

Automated Optical Inspection (AOI) System for ceramic inspection

Ceramic materials are integral to industries ranging from construction and manufacturing to electronics and healthcare. Ensuring the quality of ceramic surfaces is critical, as defects can compromise performance, durability, and aesthetic value. Traditional inspection methods, which often rely on human inspection, are time-consuming, inconsistent, and prone to errors. Machine Vision AI offers a transformative approach to ceramic surface inspection, providing automation, precision, and real-time defect detection.

This article explores the challenges of inspecting ceramic surfaces, the components of an automated inspection system, and how machine vision AI enhances the efficiency and reliability of the inspection process.

System for ceramic inspection.png)

Challenges in Ceramic Surface Inspection

Inspecting ceramic surfaces involves identifying a wide range of defects and ensuring uniformity in appearance and functionality. Key challenges include:

- Diverse Defects:

- Defects can range from cracks, chips, and pinholes to color variations, glaze inconsistencies, and surface roughness.

- Many defects are microscopic, requiring high-resolution imaging to detect.

- Reflective and Textured Surfaces:

- Polished or glazed ceramics can produce glare, complicating image capture and analysis.

- Textured surfaces require advanced imaging techniques to differentiate between design features and actual defects.

- High Production Volumes:

- Manufacturers often produce ceramics in large quantities, necessitating fast and efficient inspection systems.

- Manual Inspection Limitations:

- Human inspectors can miss subtle defects, especially during prolonged inspections or at high speeds.

- Inconsistent results and subjectivity can affect quality control.

- Variety in Shapes and Sizes:

- Ceramic products, such as tiles, plates, or electronic components, vary widely in dimensions, requiring adaptable inspection systems.

Automated Inspection with Machine Vision AI

Machine vision AI combines high-resolution imaging, tailored lighting solutions, and AI-powered defect detection algorithms to address these challenges effectively. These systems automate the inspection process, delivering consistent, accurate, and real-time results. Key Components of a Machine Vision AI System for Ceramic Inspection are:

Imaging Solutions Accurate defect detection begins with capturing high-quality images of ceramic surfaces. Intelgic provides imaging solutions tailored to meet the specific requirements of ceramic inspection:

- High-Resolution Cameras:

- Capture detailed images to detect defects as small as a few microns.

- Multi-camera setups can be used for inspecting larger ceramic surfaces or products with complex geometries.

- CIS (Contact Image Sensor) Modules:

- Ideal for inspecting continuous ceramic sheets or tiles at high speeds.

- Customizable to match the dimensions of the inspected material, ensuring consistent imaging across the entire surface.

- Specialized Imaging Systems:

- Compact cameras for inspecting intricate ceramic parts, such as electronic substrates or medical implants.

Lighting Solutions Proper illumination is crucial for highlighting surface defects, especially on reflective or textured ceramics. Key lighting techniques include:

- Diffuse Lighting:

- Reduces glare on polished or glazed surfaces.

- Provides even illumination for detecting fine cracks and surface irregularities.

- Directional Lighting:

- Enhances the visibility of texture and contour defects.

- Useful for detecting scratches, chips, or uneven glaze applications.

- Multi-Angle Lighting:

- Captures defects from various perspectives to ensure comprehensive inspection.

- Suitable for complex shapes or highly textured surfaces.

Machine Vision AI Software The core of an automated inspection system is the AI-powered software that processes captured images, detects defects, and provides actionable insights:

- Defect Detection Algorithms:

- Trained on datasets of ceramic defects, these algorithms identify cracks, chips, pinholes, stains, and other anomalies.

- Capable of distinguishing between acceptable natural variations and true defects.

- Surface Uniformity Analysis:

- Ensures consistent color, texture, and glaze application across ceramic products.

- Real-Time Processing:

- Analyzes images instantly, providing immediate feedback for sorting or corrective actions.

- Customizable Models:

- Adapts to the unique inspection requirements of different ceramic products, such as tiles, plates, or components.

Electromechanical Integration To ensure smooth operation, the inspection system is integrated with electromechanical components:

- Automated Conveyors:

- Transport ceramic products under the imaging devices at consistent speeds.

- Ensures alignment and stability during inspection.

- Sorting Mechanisms:

- Automatically separate defective items from acceptable products based on inspection results.

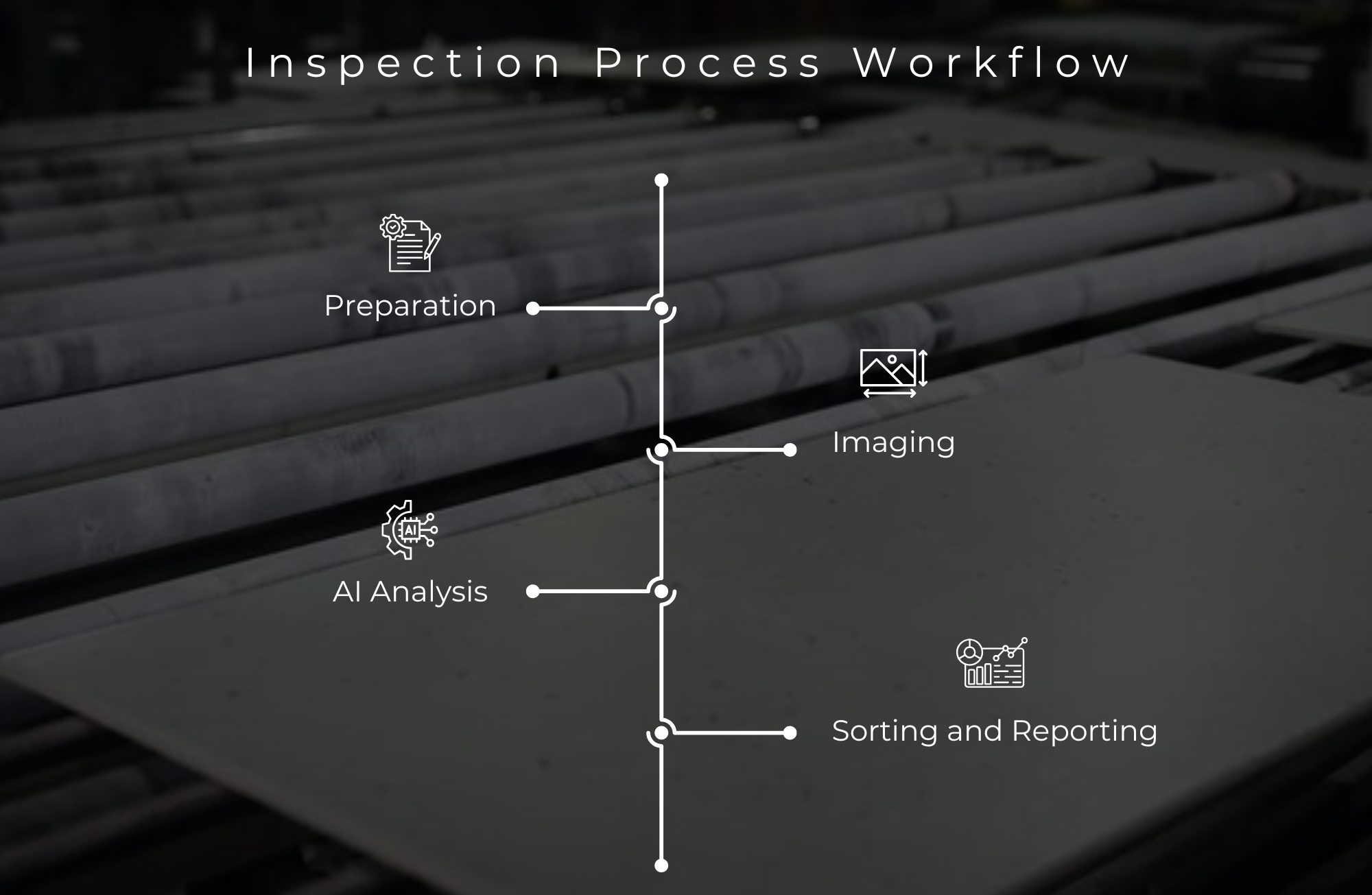

Inspection Process Workflow

- Preparation

- Ceramic products are loaded onto a conveyor system.

- Products are aligned and stabilized for consistent imaging.

- Imaging

- High-resolution cameras or CIS modules capture images of the surface.

- Lighting systems illuminate the surface to enhance defect visibility.

- AI Analysis

- The machine vision AI software processes images to detect defects, analyze surface uniformity, and classify defects by severity.

- Results are displayed in real-time for immediate decision-making.

- Sorting and Reporting

- Defective products are flagged and separated automatically.

- Detailed inspection reports are generated, including defect locations, classifications, and images.

Applications of Ceramic Inspection Automation

Automated ceramic inspection systems are versatile and can be used in various industries:

- Construction:

- Inspect tiles, slabs, and other construction ceramics for cracks, chips, and surface irregularities.

- Consumer Goods:

- Ensure the quality of ceramic plates, bowls, and decorative items.

- Electronics:

- Detect defects in ceramic substrates, insulators, and capacitors used in electronic devices.

- Medical Devices:

- Inspect ceramic components in implants and surgical instruments for structural integrity and surface finish.

Benefits of Automated Ceramic Inspection

- Enhanced Accuracy:

- Detects even the smallest defects with high precision, ensuring consistent quality.

- Increased Efficiency:

- Speeds up the inspection process, enabling high-throughput production without compromising accuracy.

- Reduced Costs:

- Minimizes waste by identifying defective products early in the production process.

- Reduces the need for manual inspection, lowering labor costs.

- Objective and Consistent Results:

- Eliminates subjectivity and human error, ensuring reliable inspection outcomes.

- Scalability and Adaptability:

- Systems can be customized for various ceramic products and production volumes.

Why Choose Intelgic for Ceramic Surface Inspection Automation?

Intelgic provides state-of-the-art machine vision AI systems tailored to the specific requirements of ceramic inspection. Our expertise includes:

- Comprehensive Solutions:

Integrated imaging, lighting, and AI software for a seamless inspection process. - Customizable Systems:

Adaptable to different ceramic products, defect types, and manufacturing environments. - Advanced AI Technology:

Capable of real-time defect detection and analysis with high precision. - Global Expertise with Local Support:

Based in Utah, USA, Intelgic serves manufacturers nationwide with cutting-edge solutions and dedicated customer support.

Automating ceramic surface inspection with machine vision AI is a game-changer for manufacturers, ensuring precision, efficiency, and consistency in quality control. By integrating high-resolution imaging, optimized lighting, and AI-powered software, Intelgic delivers tailored solutions that address the unique challenges of ceramic inspection. Whether you produce tiles, electronic components, or medical devices, Intelgic’s systems can help you achieve superior quality, reduce waste, and stay competitive in the market.

Contact Intelgic today to learn how our ceramic surface inspection systems can transform your production process and elevate your product quality.