Automated Optical Inspection (AOI) System for Automotive Parts Inspection

Published on: Dec 04, 2024

Written by: Soumen das

Inspection Process Automation for Automotive

In the automotive industry, maintaining stringent quality standards is critical for ensuring safety, performance, and customer satisfaction. Automated Optical Inspection (AOI) systems have become a cornerstone for achieving these goals, offering precision, efficiency, and reliability in detecting defects in automotive parts. From inspecting small components like screws and bolts to complex assemblies such as engine blocks and chassis systems, AOI systems are transforming the way manufacturers maintain quality control.

Inspection Challenges for Automotive Industry

The automotive industry demands perfection in every component, as even minor defects can lead to significant safety risks, performance issues, or costly recalls. Traditional inspection methods, such as manual inspections, are often slow, inconsistent, and prone to human error. AOI systems address these challenges by automating the inspection process and ensuring that every part meets the highest quality standards.

Key Challenges in Automotive Parts Inspection

- Complex Geometries: Automotive parts often have intricate shapes and features, requiring advanced imaging solutions to inspect all surfaces and details.

- High Production Volumes: The industry operates at high speeds, demanding fast and accurate inspection systems.

- Material Diversity: Parts are made from various materials such as metals, plastics, and composites, each with unique inspection requirements.

- Micron-Level Defects: Small defects like cracks, scratches, and dimensional inaccuracies can compromise part performance and safety.

Essential Components of AOI Systems for Automotive Parts Inspection

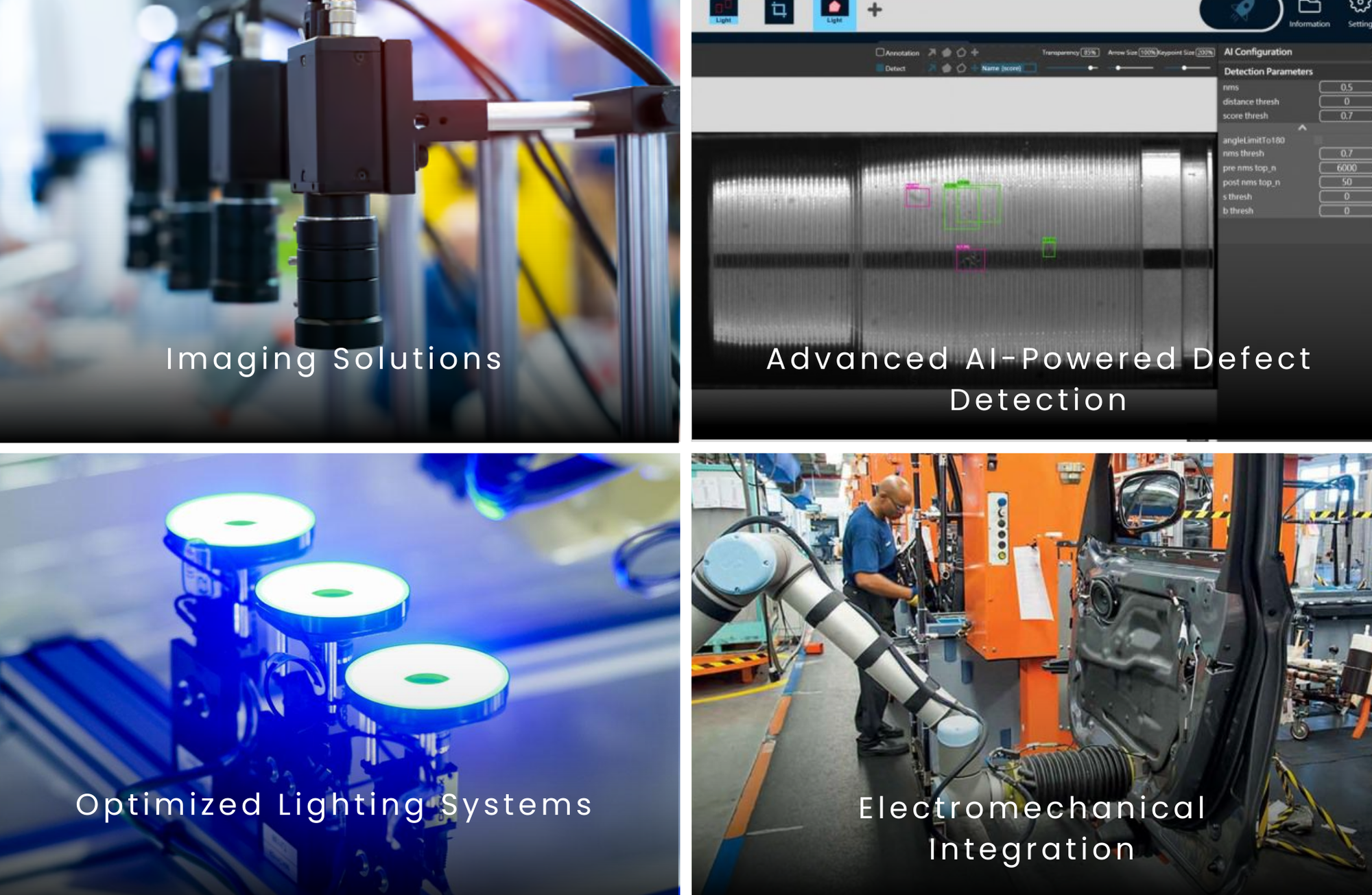

High-Resolution Imaging Solutions

The foundation of an AOI system is its imaging capability, which ensures every part is thoroughly inspected.

- CIS (Contact Image Sensors):

Ideal for inspecting flat or continuous surfaces, such as metal sheets, leather material, glasses and similar products, with high-speed and high-resolution line-scan imaging. - Machine Vision Cameras:

High-resolution cameras capture intricate details of complex parts, such as gears, pistons, and engine blocks, enabling the detection of micro-defects. - Multi-Camera Systems:

For complex assemblies, large parts and multi surface parts, synchronized multi-camera setups provide 360-degree coverage to inspect all surfaces and features.

Advanced AI-Powered Defect Detection

Intelgic’s Live Vision AI software is the brain behind its AOI systems, delivering real-time defect detection with precision and speed.

- Defect Types Detected:

- Splits, Cracks, scratches, and dents

- Surface irregularities and texture deviations

- Dimensional inaccuracies and misalignments

- Coating inconsistencies and discoloration

- Customizable AI Algorithms:

The AI models are tailored to specific part types, materials, and defect types, ensuring high detection accuracy and minimal false positives. - Real-Time Processing:

The system processes high-speed video streams, identifying defects instantly and providing actionable insights.

Lighting plays a crucial role in capturing clear images and ensuring defects are visible.

- Diffuse Lighting:

Reduces glare and ensures uniform illumination, especially on reflective metal surfaces. - Directional Lighting:

Enhances contrast to highlight surface irregularities like scratches and dents. - Multi-Angle Lighting:

Captures defects from various perspectives, ensuring comprehensive coverage for complex geometries.

Electromechanical Integration

To handle diverse automotive parts, Intelgic integrates custom electromechanical systems into its AOI solutions.

- Robotic Arms:

Position and rotate parts for complete surface inspection. Robotic arms are used to automate complex inspection tasks such as mounting cameras, lighting and control uniform movement of cameras and lighting devices. - Precision Conveyors:

Transport parts under imaging systems at consistent speeds. - Automated Sorting Mechanisms:

Separate defective parts from acceptable ones, streamlining the inspection process.

AOI Systems for Versatile Automotive Parts Inspection

AOI systems are versatile and can be used across various automotive components and assemblies:

- Metal Components:

- Inspect engine blocks, gears, shafts, and chassis components for cracks, wear, and dimensional accuracy.

- Plastic and Composite Parts:

- Ensure the integrity of dashboards, bumpers, and interior trims by detecting surface defects and inconsistencies.

- Welding and Soldering Joints:

- Verify the quality of welds and soldered connections in assemblies such as exhaust systems and electronics.

- Electronics and PCB Assemblies:

- Inspect printed circuit boards and electronic modules for alignment, soldering defects, and connectivity issues.

- Coated and Painted Surfaces:

- Detect coating defects, discoloration, and uneven paint application on metal or plastic parts.

Intelgic’s Expertise in AOI for Automotive Parts

Intelgic stands out as a leading provider of custom AOI systems tailored to the automotive industry. Our solutions are built with:

- State-of-the-Art AI Software:

Designed for accurate anomaly detection and real-time processing. - Customized Imaging Solutions:

High-resolution cameras and CIS sensors tailored to the specific needs of automotive part inspection. - Electromechanical Systems:

Fully integrated robotic arms, conveyors, and sorting mechanisms for seamless automation. - Comprehensive Support:

From consultation and system design to implementation and training, Intelgic ensures your AOI system operates flawlessly.

Large Parts Inspection in Automotive Manufacturing

Large automotive parts, such as chassis, doors, bonnets, and panels, require specialized inspection solutions due to their size, complexity, and diverse inspection criteria. Intelgic’s Automated Optical Inspection (AOI) systems are designed to handle these challenges effectively, ensuring precision and efficiency for large parts inspection.

Inspection of Moving Large Parts

Certain large automotive components, such as chassis for large trucks, can measure over 20 feet in length. Inspecting such parts demands advanced imaging systems capable of covering the entire length with high precision.

- Line-Scan Cameras for Moving Parts:

- Line-scan cameras are ideal for inspecting large parts as they move along a conveyor system.

- These cameras capture detailed images line by line, enabling the detection of minor defects such as splits, cracks, scratches, and dents, even on massive components.

- High-speed data capture ensures seamless inspection without slowing production.

Inspection of Stationary Parts

For parts like doors, bonnets, and panels, which are typically inspected while stationary, Intelgic uses area-scan cameras with large fields of view (FOV).

- Inspection Criteria:

- Detection of splits, cracks, and surface scratches.

- Measurement of dimensions, hole positions, and the number of holes to ensure compliance with design specifications.

- Verification of overall part integrity and surface quality.

- Area-Scan Cameras:

- Provide comprehensive coverage of large, stationary parts with high-resolution imaging.

- Adaptable to different inspection criteria, ensuring both surface and dimensional accuracy.

Powder Coating Process Automation

In the automotive industry, powder coating is commonly applied to large parts for durability and corrosion resistance. However, identifying and labeling parts during the powder coating process, especially on hanging lines, is often done manually—a method prone to errors and inefficiencies.

- Automated Part Recognition and Labeling:

- Intelgic’s machine vision systems, combined with AI, can automate the recognition and labeling of parts during the powder coating process.

- The system compares each part with a golden template, accurately identifying and classifying parts based on their unique features, dimensions, and shapes.

- Benefits of Automation:

- Eliminates manual errors in part identification and labeling.

- Streamlines the powder coating workflow, ensuring accurate tracking of parts throughout the process.

- Enhances operational efficiency and traceability.

In the fast-paced and quality-driven automotive industry, Automated Optical Inspection (AOI) systems have become indispensable for maintaining high standards and meeting production demands. Intelgic’s custom AOI solutions deliver the precision, speed, and adaptability needed to inspect complex automotive parts and assemblies with confidence. Whether you’re inspecting gears, electronics, or painted surfaces, Intelgic’s advanced systems ensure superior quality control and operational efficiency.

Contact Intelgic today to learn how our AOI systems can revolutionize your automotive manufacturing process and elevate your quality standards.