Automating Wooden Panel Inspection using Machine Vision Cameras and AI

Published on: Feb 03, 2025

Written by: Content team, Intelgic

Automating Wooden Panel Inspection using Machine Vision Cameras and AI

Wooden panels are indispensable across a range of industries, including furniture manufacturing, construction, and interior design. Ensuring their quality is paramount, as even the most subtle imperfections can compromise both their functionality and visual appeal. Traditional manual inspection methods are not only labor-intensive but also prone to human error. The advent of automation, powered by machine vision technologies and artificial intelligence (AI), offers a transformative solution, significantly enhancing the precision and efficiency of the inspection process. This article delves into the automation of wooden panel inspection, exploring the various machine vision systems available, the pivotal role of AI in identifying defects, and how Intelgic distinguishes itself in this specialized domain.

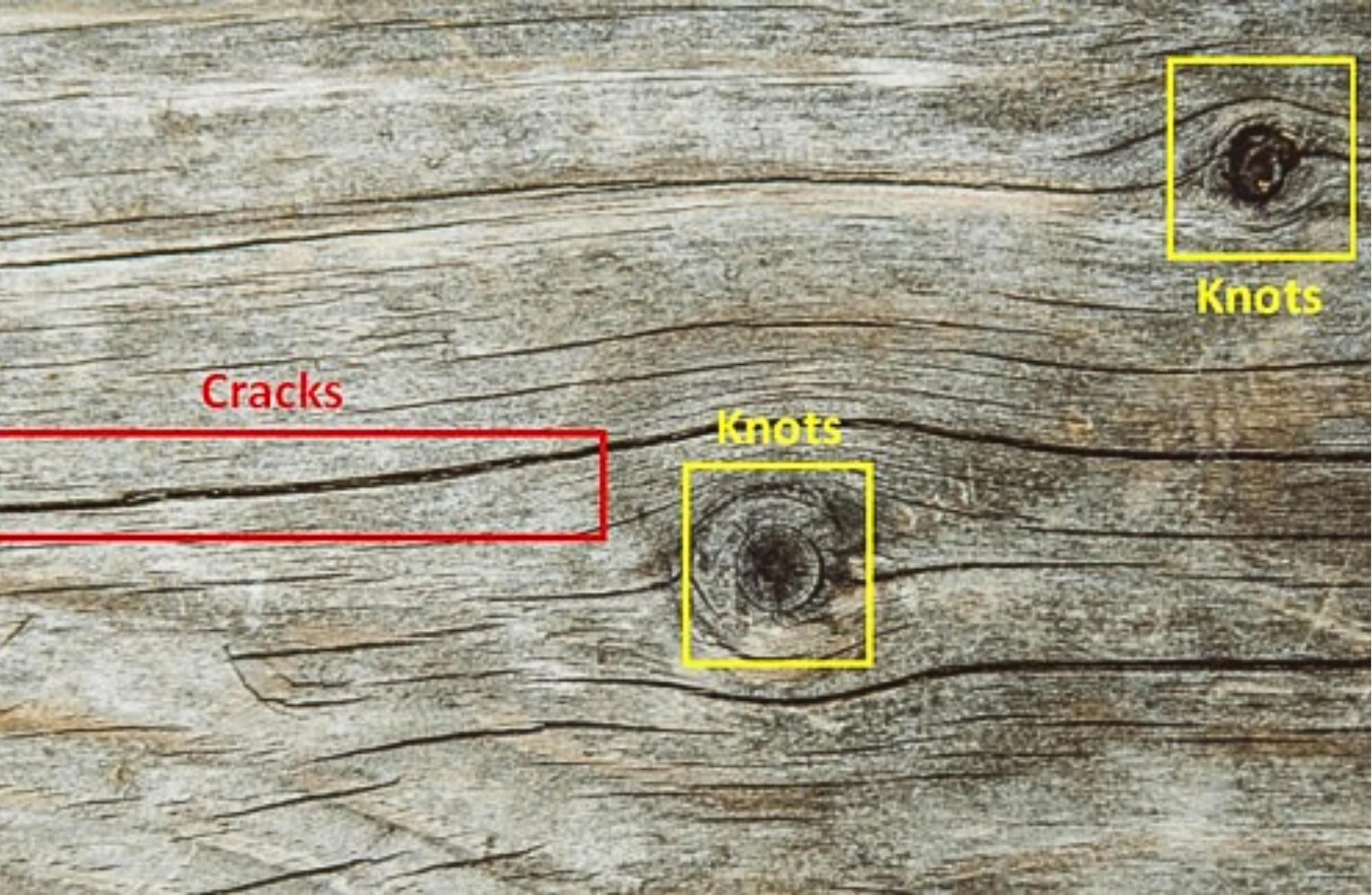

Common Defects in Wooden Panels

Wooden panels, while natural and aesthetically pleasing, are prone to several types of defects that can compromise their structural integrity and visual appeal. These defects include:

- Cracks and Splits: Resulting from internal stresses, uneven drying, or environmental factors like moisture variation, cracks and splits weaken the wood and can render panels unusable.

- Knots: Knots are areas in the wood where branches were once located. Though small knots are often acceptable, larger or mispositioned knots may weaken the panel.

- Warping: Warping occurs when moisture is absorbed or lost unevenly, causing the wood to bend or twist, which can make the panel unsuitable for installation.

- Color Inconsistencies: Variations in color and grain patterns may occur naturally in wood, but extreme inconsistencies are undesirable in finished panels.

- Scratches and Surface Imperfections: Panels can develop scratches or dents from handling, transport, or manufacturing processes, diminishing their overall quality.

- Delamination: Particularly in laminated wood panels, delamination occurs when adhesive bonds fail, causing the layers of the panel to separate.

- Thickness Variations: Inconsistent thickness across the surface of the panel can be due to improper milling or cutting, affecting the fitting and usability of the panel.

Challenges in Wooden Panel Inspection

Inspecting wooden panels on a large scale comes with several challenges:

- Surface Variability: The natural properties of wood, such as varying grain patterns, textures, and colors, can make it difficult to distinguish between defects and natural variations.

- Hidden Internal Defects: Defects such as internal cracks, moisture content variations, or delamination are often not visible on the surface, requiring advanced imaging technologies to detect.

- Speed and Throughput: Manual inspection is slow and cannot keep up with the fast pace of modern production lines. Automated systems must provide both speed and accuracy.

- Environmental Variability: Wood is highly sensitive to environmental factors such as humidity, temperature, and lighting. These factors can alter the appearance of the wood, making it challenging to detect defects consistently.

- Complex Geometry: Panels may have irregular shapes, warped surfaces, or varying thicknesses, necessitating adaptable inspection systems capable of analyzing these complex geometries.

Key Components of AI Powered Wooden Panel Inspection

Automating the inspection of wooden panels involves integrating various technologies that work in tandem to capture, process, and analyze images for defects. Key components of this process include advanced imaging systems, lighting systems, and AI software. Each element plays a critical role in ensuring accurate and efficient defect detection.

Advanced Imaging Systems

In wooden panel inspection, various machine vision cameras are used to capture detailed images and enable defect detection. These cameras are essential for automating the process and ensuring consistent quality. Types of cameras used include:

- Line Scan Cameras: These cameras capture images one line at a time as the panel moves through the inspection area. Line scan cameras are ideal for high-speed applications and provide detailed, continuous inspection of long wooden panels, detecting defects along their entire length.

- Area Scan Cameras: These cameras capture the entire surface of the panel in a single shot, providing a comprehensive view of the panel. Area scan cameras are effective for detecting surface defects and are commonly used for applications that require high-resolution images for detailed analysis.

- Infrared (IR) Cameras: These cameras detect temperature variations across the surface, identifying hidden defects such as moisture content or internal cracks.

- 3D Cameras: These cameras use stereo vision or laser triangulation to measure depth, helping detect dimensional issues such as warping or inconsistent thickness.

Types of Illuminations for Lighting Systems

Lighting plays a crucial role in machine vision systems, as it directly impacts the quality of the captured images. The right illumination ensures that defects, no matter how subtle, are visible to the cameras. Several types of lighting are used in automated wooden panel inspection:

- Diffuse Lighting: Spreads light evenly over the surface, reducing shadows and highlighting surface defects like scratches and color inconsistencies.

- Backlighting: Illuminates the panel from behind to create high contrast, helping detect internal defects, cracks, or delamination.

- Structured Light: Projects a pattern (grid or stripe) onto the panel to detect geometric defects like warping or irregular thickness.

- Direct or Point Lighting: Focuses on specific areas, providing high contrast to highlight localized defects such as knots or cracks.

- Ultraviolet (UV) Lighting: Reveals defects or contaminants, such as moisture or oil stains, that are not visible under normal lighting.

AI Software for Defect Detection

Intelgic's Live Vision software plays a central role in the automated inspection of wooden panels, analyzing images captured by machine vision cameras to detect defects based on learned patterns. The software utilizes several key AI technologies to enhance accuracy. Machine learning algorithms, trained on extensive datasets of labeled images, allow the system to classify defects by learning from both defective and non-defective panels. Over time, this enables the AI to improve its defect identification capabilities. Deep learning models, particularly convolutional neural networks (CNNs), are highly effective at recognizing complex patterns, such as fine cracks or subtle grain variations, that might be difficult for human inspectors to detect. Additionally, anomaly detection techniques within Intelgic's Live Vision software compare panels to a "perfect" model, flagging any deviations as potential defects, making it well-suited for identifying unusual or previously unrecognized issues.

Inspection Process Flow

The automation process for wooden panel inspection using machine vision and AI follows a structured workflow:

- Panel Placement: Wooden panels are placed on an automated conveyor or transport system, which moves them through the inspection station.

- Image Capture: The area scan or line scan cameras capture images of the panel's surface as it passes through the inspection area. Multiple camera angles or imaging systems may be used to provide a comprehensive analysis of the panel.

- Image Preprocessing: The captured images are processed to enhance their quality. Preprocessing steps include noise reduction, contrast adjustment, and image sharpening to highlight defects.

- Defect Detection: The AI software analyzes the images to detect and classify defects such as cracks, warping, color inconsistencies, and knots. The software uses deep learning models to identify patterns in the wood and flag defects.

- Real-Time Feedback: The system provides real-time feedback to operators and the production line, enabling immediate corrective actions if necessary.

Benefits of Using AI for Wooden Panel Inspection

AI-powered machine vision systems offer numerous advantages in wooden panel inspection:

- Accuracy and Precision: AI systems are capable of detecting even the smallest defects with high accuracy, reducing the risk of human error.

- Speed: Automated systems can inspect large volumes of panels quickly, ensuring high throughput and minimizing production delays.

- Cost Efficiency: By reducing the need for manual inspection and early defect detection, AI systems help lower production costs and minimize material waste.

- Consistency: Unlike human inspectors, AI systems are not subject to fatigue and can maintain consistent performance over extended periods, ensuring uniform quality control.

- Scalability: AI systems can easily scale to accommodate higher production volumes, making them suitable for both small and large manufacturing operations.

How Intelgic Stands Out in Wooden Panel Inspection

Intelgic stands at the forefront of AI-driven industrial automation, particularly excelling in wooden panel inspection. What truly differentiates Intelgic is its focus on providing all-encompassing, tailor-made solutions that cater to the individual demands of each client, ensuring the highest standards of accuracy and efficiency throughout the inspection process. Key advantages include:

- Tailored AI Models: Intelgic works with manufacturers to create custom AI models, trained on specific panel types and production processes, ensuring high accuracy and relevance in defect detection.

- Integrated Solutions: Intelgic offers complete, integrated solutions that combine advanced machine vision systems, Live Vision AI software, and real-time analytics for a seamless inspection process.

- Ongoing Support: Intelgic provides continuous optimization and support, ensuring that systems remain efficient and accurate as production conditions evolve.

In conclusion, automating the inspection of wooden panels using machine vision cameras, lighting systems, and AI provides manufacturers with a powerful tool to enhance quality control. By integrating area scan and line scan cameras, advanced lighting techniques, and AI software, companies can significantly improve defect detection, efficiency, and consistency. Intelgic’s customized solutions ensure that manufacturers can leverage the full potential of AI to streamline production and maintain high standards of quality.